Title: “SourcifyChina: Your Reliable Source for Premium Stainless Metal Fabrication from China Factories”

When it comes to high-quality stainless metal fabrication, SourcifyChina is your go-to reliable partner. With top-tier China factory connections, we ensure precision, durability, and exceptional craftsmanship for all your fabrication needs. Trust SourcifyChina for unparalleled excellence.

SourcifyChina Factory offers unparalleled expertise in stainless metal fabrication, ensuring top-quality products that meet international standards. Their advanced technology and skilled workforce guarantee precision and durability.

Choosing SourcifyChina means reliable delivery times, crucial for maintaining your supply chain efficiency. They understand the importance of timely deliveries in a competitive market.

Their competitive pricing ensures that you get the best value for your investment, without compromising on quality. SourcifyChina’s commitment to cost-effective solutions makes them a preferred choice for many buyers.

Customer support at SourcifyChina is exceptional, with a dedicated team ready to assist you at every step. Their focus on building long-term relationships ensures a seamless purchasing experience.

Finally, their robust quality control measures ensure that each product undergoes strict inspections, meeting all quality benchmarks. With SourcifyChina, you can be assured of receiving only the best stainless metal fabrication products.

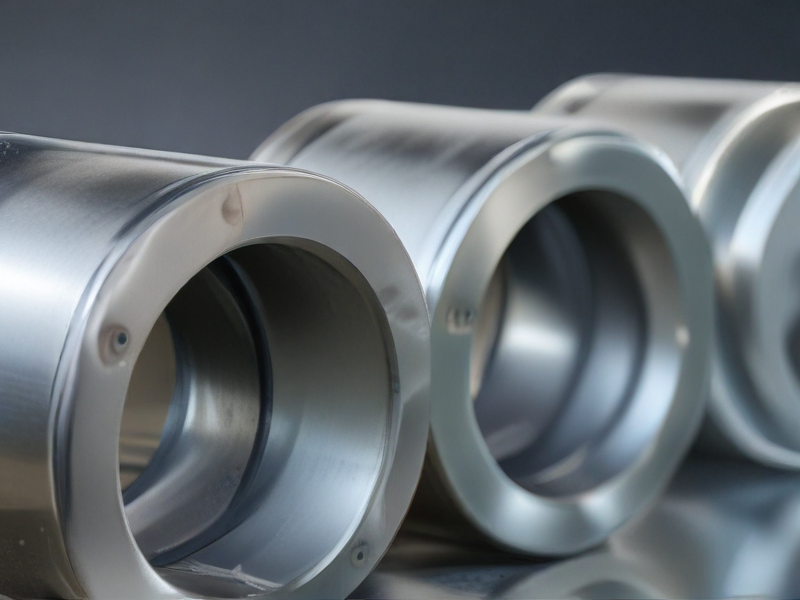

Stainless metal fabrication encompasses various types, techniques, and options to create durable and corrosion-resistant products. This process is essential in industries like construction, automotive, and healthcare due to stainless steel’s robustness and versatility.

– Types of Stainless Steel:

– Austenitic

– Ferritic

– Martensitic

– Duplex

– Precipitation-Hardening (PH)

– Techniques for Fabrication:

– Cutting: Laser cutting, water jet cutting, and plasma cutting.

– Forming: Bending, deep drawing, and roll forming.

– Joining: TIG welding, MIG welding, and spot welding.

– Finishing: Polishing, brushing, and electroplating.

– Options and Customizations:

– Custom Shapes: Tailored designs and bespoke dimensions.

– Surface Treatments: Anodizing, passivation, and powder coating.

– Perforations and Patterns: Custom hole patterns for aesthetic and functional purposes.

– Precision Engineering: High tolerance and precision parts for critical applications.

– Applications:

– Construction: Handrails, cladding, and structural components.

– Automotive: Exhaust systems, trim, and structural parts.

– Healthcare: Surgical instruments, hospital furniture, and sanitary fittings.

– Food & Beverage: Processing equipment, storage tanks, and kitchenware.

Stainless metal fabrication offers a plethora of options to meet various industrial needs, ensuring both aesthetic appeal and durability. With advancements in technology, the customization possibilities are virtually limitless, allowing for innovative and precise solutions across multiple sectors.

Stainless metal fabrication is indispensable in numerous industries due to its durability and resistance to corrosion. Its applications span across medical, food processing, automotive, and construction sectors.

– Medical Equipment: Surgical instruments, hospital beds, and medical devices.

– Food Processing: Machinery, storage tanks, and kitchen equipment.

– Automotive: Exhaust systems, trim, and structural components.

– Construction: Structural supports, handrails, and façade elements.

– Aerospace: Aircraft components and support structures.

– Marine: Shipbuilding, railings, and fittings.

– Chemical Processing: Reactors, pipelines, and storage vessels.

– Pharmaceuticals: Cleanroom equipment, shelving, and conveyors.

– Energy: Oil and gas platforms, wind turbines, and nuclear plant components.

– Electronics: Enclosures, connectors, and semiconductor manufacturing tools.

– Architecture: Balustrades, cladding, and sculpture.

– Consumer Goods: Appliances like refrigerators, dishwashers, and cutlery.

– Water Treatment: Filtration systems, pumps, and desalination equipment.

– HVAC: Ductwork, boilers, and heat exchangers.

– Tool and Die: Precision tools and molds.

– Militaristic: Armored vehicles and missile components.

– Agricultural: Dairy equipment, silos, and fencing.

– Mining: Screens, chutes, and hoppers.

– Renewable Energy: Solar panel structures and frame mounts.

– Telecommunications: Antennas, cabinets, and mounting brackets.

Stainless metal fabrication plays a critical role in enhancing the performance and longevity of products across these diverse areas.

SourcifyChina specializes in high-grade stainless metal fabrication, offering remarkable solutions for diverse industrial applications. Their services encompass precise cutting, welding, and forming, ensuring each product meets exacting standards.

The company uses top-quality stainless steel materials renowned for their durability and resistance to rust and corrosion. This choice of material guarantees longevity and superior performance in various environments, including harsh and demanding conditions.

Customers benefit from SourcifyChina’s advanced manufacturing techniques, which combine innovation with meticulous craftsmanship. The result is a lineup of stainless steel products that are as robust as they are reliable, perfect for a wide range of uses.

Whether for automotive, construction, or consumer goods, SourcifyChina provides tailored solutions to meet specific requirements. Their commitment to quality and precision ensures that every project is executed flawlessly, reinforcing their reputation as industry leaders.

In essence, SourcifyChina’s stainless metal fabrication leverages superior materials and state-of-the-art technology to deliver excellence. Their unwavering dedication to quality and customer satisfaction solidifies their standing in the market, making them a trusted partner for stainless steel needs.

SourcifyChina specializes in stainless metal fabrication, embracing rigorous quality control measures in their manufacturing process. Starting with raw materials, they ensure all inputs meet stringent industry standards to guarantee high-quality end products.

Advanced machinery and technology are employed to maintain precision and consistency throughout each production stage. CNC machines offer exacting tolerances, while automated welding equipment ensures uniformity and strength in metal joints.

The quality control team conducts frequent inspections, from material receipt to final assembly. Each part undergoes dimensional checks, surface inspections, and stress testing to identify any deviations from specifications.

For assurance, SourcifyChina follows ISO 9001 standards, embedding quality management into every layer of its operations. Periodic audits and continuous improvement initiatives help maintain compliance and enhance manufacturing processes.

Final product testing includes load and endurance tests to validate durability and performance. Only fully compliant items advance to packaging, ensuring that customers receive reliable, top-tier metal fabrications.

SourcifyChina also values customer feedback, implementing suggestions to refine their processes further. This commitment not only meets but often exceeds customer expectations, fostering trust and long-term partnerships.

Sustainability and efficiency are also vital, with measures to minimize waste and energy use, aligning with modern environmental standards. The controlled environment is critical in preventing contamination and ensuring product purity.

Training programs keep staff updated on the latest quality standards and technological advances. Skilled professionals, dedicated to excellence, form the backbone of SourcifyChina’s high-quality production.

In conclusion, SourcifyChina’s meticulous quality control in stainless metal fabrication ensures robust, precise, and reliable products, continually exceeding industry benchmarks and customer expectations. Their holistic approach to quality management fosters consistent improvements and sustained excellence.

SourcifyChina specializes in stainless metal fabrication, offering comprehensive services that cater to diverse industrial needs. Their capability includes precision cutting, bending, welding, and assembling stainless steel components.

Utilizing advanced technology, SourcifyChina ensures high-quality outcomes with exact tolerances. Their fabrication process incorporates CNC machining and laser cutting to guarantee precision and consistency across all projects.

The company prides itself on robust design support and engineering solutions. They work closely with clients to develop custom metal fabrication solutions, ensuring that each product meets specific requirements and standards.

SourcifyChina’s experienced team executes projects with impeccable attention to detail. Their skilled workforce ensures that every fabricated metal component reflects superior craftsmanship and durability.

They also place a strong emphasis on quality control, rigorously testing and inspecting all products. This commitment to excellence has earned them a reputation for reliability in stainless metal fabrication.

Finally, SourcifyChina is dedicated to sustainable practices, minimizing waste and utilizing eco-friendly materials. Their approach not only supports environmental sustainability but also promotes cost-efficiency for clients in the long run.

Stainless steel fabrication offers numerous advantages, making it a preferred choice in various industries due to its durability, corrosion resistance, and aesthetic appeal.

– Durability: Stainless steel is exceptionally durable, with high resistance to wear and tear, making it ideal for both structural applications and consumer products.

– Corrosion Resistance: One of the main benefits is its resistance to rust and corrosion, even in harsh environments, which extends the lifespan of the fabricated products.

– Low Maintenance: Stainless steel requires minimal maintenance due to its self-healing oxide layer, reducing long-term operational costs.

– Hygienic: Stainless steel is non-porous and easy to clean, making it a preferred material in hygienic environments such as kitchens, hospitals, and laboratories.

– Aesthetic Appeal: It offers a sleek, modern look that is visually appealing, making it popular in architectural and design applications.

– Sustainability: Stainless steel is 100% recyclable, contributing to environmental sustainability and making it an eco-friendly material choice.

– Heat and Fire Resistance: It can withstand high temperatures and fire without degrading, enhancing safety in various applications.

– Versatility: Stainless steel can be easily shaped, welded, and manufactured, allowing for a wide range of uses from industrial equipment to decorative elements.

– Economic Efficiency: Although the initial cost may be higher, its longevity and low maintenance requirements offer cost efficiency over time.

– Strength-to-Weight Ratio: Stainless steel has a high strength-to-weight ratio, which allows for the production of strong yet lightweight components.

Incorporating stainless steel into fabrication processes ensures a long-lasting, reliable, and environmentally considerate outcome that meets a variety of functional needs while also enhancing the aesthetic value of the final product.

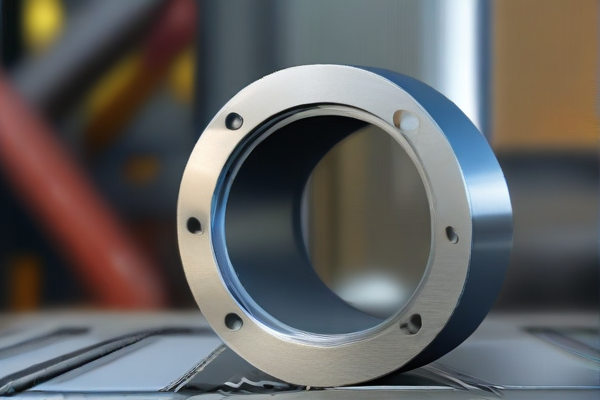

Stainless metal fabrication boasts durability, corrosion resistance, and aesthetic appeal, making it ideal for diverse applications. Key features include:

– Durability: Stainless steel offers exceptional strength and longevity, ensuring structures and components remain intact over time.

– Corrosion Resistance: Its natural resistance to rust and corrosion makes it suitable for environments exposed to moisture and chemicals.

– Aesthetic Appeal: Stainless steel’s sleek, modern look enhances the visual appeal of both industrial and residential projects.

– Versatility: Adaptable to various forms and functions, stainless steel can be molded, welded, and customized to meet specific project needs.

– Hygienic Properties: Non-porous surface prevents bacteria buildup, making it ideal for medical and food preparation applications.

– Temperature Resilience: Withstands extreme temperatures, maintaining integrity in both high heat and freezing conditions.

– Recyclability: Environmentally friendly, stainless steel is fully recyclable, contributing to sustainable building practices.

– Low Maintenance: Requires minimal upkeep due to its resistant properties, reducing long-term maintenance costs.

– Precision Engineering: Enables detailed and precise fabrication, crucial for intricate designs and specialized equipment.

– Non-Magnetic Options: Certain grades provide non-magnetic properties, beneficial in specific industries like electronics and medical devices.

SourcifyChina is a leading manufacturer specializing in stainless metal fabrication. They offer a wide range of customized products tailored to meet specific client requirements. Their state-of-the-art facilities ensure precision and high-quality output.

From stainless steel tanks and pressure vessels to kitchen equipment and architectural elements, SourcifyChina delivers intricate designs with utmost attention to detail. Their skilled workforce and advanced technology make them a preferred choice for bespoke metal sheets and components.

Committed to quality, SourcifyChina follows stringent quality control measures. Each custom product undergoes thorough inspections, ensuring durability and compliance with international standards. They provide comprehensive solutions from conceptual design to final delivery.

With a strong focus on customer satisfaction, SourcifyChina collaborates closely with clients, understanding their unique needs. Their responsive approach and prompt communications ensure projects run smoothly and efficiently. They also offer competitive pricing, making high-quality custom metal fabrication more accessible.

In addition to their custom products, SourcifyChina excels at complex projects. They manage everything from prototyping to production for large-scale industrial needs. Their holistic project management approach supports clients in achieving project goals within set timelines and budgets.

SourcifyChina’s dedication to innovation and excellence positions them as a trusted partner in the metal fabrication industry. They continuously invest in new technologies and training programs to stay ahead of market demands. By doing so, they maintain a competitive edge and deliver superior products.

For businesses seeking reliable and top-tier stainless metal fabrication services, SourcifyChina offers unmatched expertise and quality. Their commitment to precision, customer service, and innovation makes them a standout player in the market. Partnering with SourcifyChina ensures your custom products and projects are handled with the highest level of professionalism and care.

SourcifyChina is a renowned company specializing in stainless metal fabrication, providing comprehensive solutions tailored to meet the diverse needs of global industries. With a dedicated team of skilled engineers and state-of-the-art manufacturing facilities, the company excels in delivering high-quality, custom-fabricated stainless steel components and structures. Leveraging cutting-edge technology and adhering to stringent quality standards, SourcifyChina ensures precision and durability in every product they create. Their extensive range of services includes laser cutting, welding, bending, and surface finishing, making them a one-stop-shop for all metal fabrication needs. Committed to client satisfaction, they offer innovative, cost-effective solutions and exceptional customer service, earning them a reputation as a trusted partner in the metal fabrication industry. Whether it’s for industrial parts, architectural elements, or bespoke projects, SourcifyChina delivers excellence with reliability and efficiency.

Stainless metal fabrication plays an indispensable role in the aerospace industry, where the demand for materials that offer high strength-to-weight ratios, corrosion resistance, and durability is paramount. The stringent environmental conditions encountered in aviation—ranging from high-altitude low temperatures to continuous exposure to UV radiation—necessitate the use of robust materials that can withstand such harsh environments. Stainless steel, with its resistance to oxidation and excellent mechanical properties, is a prime choice for constructing various components like aircraft frames, engine parts, and landing gear assemblies. The precision and reliability afforded by stainless metal fabrication processes ensure that these components meet the rigorous safety and performance standards essential for modern aerospace engineering.

In the defense and marine sectors, the application of stainless metal fabrication is equally critical. Military equipment and naval vessels are often deployed in extreme conditions, including saltwater environments that can accelerate corrosion. Utilizing stainless steel in the construction of submarines, aircraft carriers, and other maritime structures provides a means to combat these corrosive challenges while maintaining structural integrity. Furthermore, the defense sector leverages stainless steel’s durability and strength in the manufacturing of armor, missile components, and various other defense apparatuses. The ability to precisely fabricate metal components ensures the functionality and reliability of sophisticated defense systems, where even minor failures can have catastrophic consequences. Through cutting-edge stainless metal fabrication techniques, these industries can produce complex, high-performance parts that are crucial for operational success and long-term sustainability.

Stainless metal fabrication plays a pivotal role in the automotive industry, where durability, strength, and resistance to corrosion are paramount. Car manufacturers rely heavily on stainless steel components for critical applications such as exhaust systems, structural body parts, and various engine components. The use of stainless steel ensures that these parts can withstand extreme temperatures, resist rust and corrosion, and maintain their integrity over time, even under strenuous conditions. This leads to enhanced vehicle longevity, better safety standards, and reduced maintenance costs. Furthermore, the aesthetic appeal of stainless steel, with its sleek and modern appearance, provides an attractive finish for high-end automobiles, where both performance and visual appeal are vital.

In the realm of electronics, stainless metal fabrication is equally indispensable. It’s commonly used in the manufacturing of casings and enclosures for electronic devices such as smartphones, laptops, and home appliances. The non-reactive nature of stainless steel ensures that sensitive electronic components are protected from electromagnetic interference (EMI) and radio frequency interference (RFI), thereby improving the reliability and performance of these devices. Moreover, stainless steel’s resistance to corrosion and oxidation extends the lifespan of electronic products, making them more durable in various environments, from humid tropical climates to arid desert conditions. The sleek and refined appearance of stainless steel also enhances the overall design of consumer electronics, aligning with the industry’s trends for devices that are both functional and visually appealing.

Stainless metal fabrication plays a pivotal role in the construction industry due to its inherent properties of corrosion resistance, durability, and aesthetic appeal. Structures such as bridges, buildings, and infrastructures often face harsh environmental conditions, necessitating materials that can withstand exposure to the elements without deteriorating. Stainless steel’s ability to resist corrosion by water, air, and various chemicals makes it an ideal choice for such applications. Furthermore, its high strength-to-weight ratio permits the design of lighter structures without compromising on strength or stability. Architectural elements, such as curtain walls, handrails, and decorative panels, also benefit from stainless metal fabrication due to its sleek finish and minimal maintenance requirements, thereby enhancing both the functionality and visual appeal of constructed environments.

In the energy sector, stainless metal fabrication is integral to the reliability and efficiency of various systems and infrastructures. Petroleum refineries, nuclear plants, and renewable energy facilities, such as wind and solar farms, utilize stainless steel components extensively. Its resistance to high temperatures and aggressive chemical environments ensures the safe handling of fuels and other hazardous materials, contributing to the longevity of energy infrastructure. For example, in wind turbines, stainless steel is used for components such as fasteners and internal fixtures to ensure durability and reduce maintenance needs. Similarly, solar power systems rely on stainless steel for mounting structures and other components that require weather resistance. Additionally, stainless steel piping systems are indispensable in geothermal and hydroelectric plants due to their ability to handle extreme temperatures and pressures. Overall, stainless metal fabrication underpins the robustness and efficiency of energy production and distribution networks.

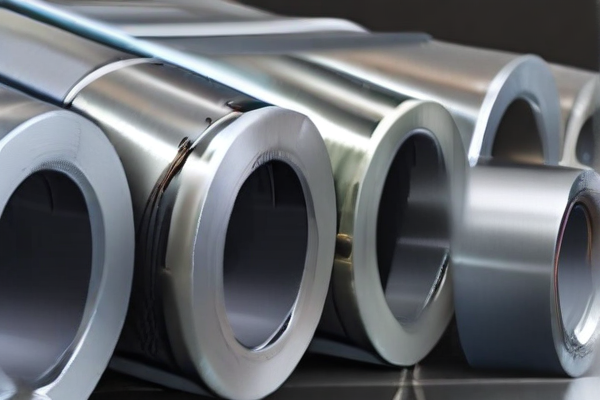

The industrial equipment sector heavily relies on stainless metal fabrication for its robustness, corrosion resistance, and durability. Stainless metal fabrication involves manipulating steel alloys that contain a minimum of 10.5% chromium, which forms an invisible and adherent chromium oxide layer that protects the metal from rust and stains. This attribute is particularly crucial in manufacturing components for industries like food processing, pharmaceuticals, and chemical production, where equipment must withstand rigorous cleaning protocols and exposure to harsh substances. The ability to fabricate complex shapes and structures from stainless steel also allows for the creation of customized machinery and components tailored to specific industrial applications, ensuring optimal performance and longevity.

Moreover, stainless metal fabrication is integral in developing high-strength equipment such as pressure vessels, heat exchangers, and storage tanks, which are essential in energy, oil, and gas industries. The material’s exceptional mechanical properties enable it to endure extreme temperatures, high pressures, and abrasive environments, thereby enhancing the safety and efficiency of industrial operations. Additionally, advancements in fabrication techniques such as laser cutting, CNC machining, and welding have further elevated the precision and quality of stainless steel components. This not only extends the service life of the equipment but also reduces maintenance costs and downtime, offering significant economic benefits to industrial operators. Overall, the application of stainless metal fabrication in the industrial equipment sector is indispensable, fostering innovation and resilience in various industrial processes.

Stainless steel metal fabrication plays a critical role in the development of medical devices due to its robustness, corrosion resistance, and biocompatibility. In medical applications, precision and reliability are paramount, and stainless steel meets these demands admirably. Devices such as surgical instruments, orthopedic implants, and dental tools often utilize stainless steel to ensure durability and sterility. The non-reactive nature of stainless steel makes it ideal for use within the human body, as it minimizes the risk of adverse reactions or infections. Furthermore, its ability to withstand repeated sterilization processes without degradation ensures that these medical devices remain effective and safe for long-term use.

Advancements in stainless steel fabrication techniques have further expanded its application in the medical field. Cutting-edge technologies such as laser cutting, CNC machining, and 3D printing enable the production of complex and highly precise components. This precision is essential for specialized instruments used in minimally invasive surgeries, where minute details and tight tolerances are crucial. Additionally, the surface finish of stainless steel can be finely controlled, providing a smooth, non-porous surface that is easy to clean and disinfect. These attributes make stainless steel not only a functional choice for medical devices but also a cost-effective one, as its longevity and reliability reduce the need for frequent replacements.

Stainless metal fabrication, a vital process in both machining and manufacturing, involves the creation of components and structures from stainless steel through techniques like cutting, bending, welding, and assembling. Machining stainless steel requires specialized tools and approaches due to its hardness and resistance to wear and heat. Advanced techniques such as CNC (Computer Numerical Control) machining enable precision and efficiency, allowing for the creation of intricate designs and tight tolerances that are essential in industries such as aerospace, automotive, and medical devices. These precise methods ensure consistent quality and durability of the final products, meeting the rigorous standards demanded by these sectors.

In manufacturing, stainless steel is celebrated for its exceptional corrosion resistance, strength, and aesthetic appeal, making it a preferred material for both functional and decorative applications. Stainless metal fabrication in manufacturing covers a wide range of products including kitchen equipment, architectural components, industrial machinery, and transportation parts. The inherent properties of stainless steel, such as its non-reactive nature and ease of sanitation, make it indispensable in food processing and pharmaceutical industries where hygiene is paramount. Additionally, developments in fabrication technologies, like laser cutting and robotic welding, have enhanced production speed and accuracy, allowing manufacturers to produce high-quality stainless steel products more efficiently and cost-effectively.

Sure, here are some FAQs with answers for manufacturing stainless metal fabrication quality work from SourcifyChina factory:

Q1: What types of stainless metal fabrication services does SourcifyChina offer?

A1: SourcifyChina offers a comprehensive range of stainless metal fabrication services, including cutting, bending, welding, machining, and finishing. We cater to various industries, ensuring high-quality and precision in each project.

Q2: How does SourcifyChina ensure the quality of their stainless metal fabrication work?

A2: We implement stringent quality control measures, including ISO certification standards, regular inspections, and rigorous testing protocols. Our skilled professionals and state-of-the-art machinery guarantee top-notch quality in every fabrication project.

Q3: Can SourcifyChina handle custom stainless metal fabrication projects?

A3: Absolutely! SourcifyChina specializes in customized stainless metal fabrication, tailored to meet the specific requirements of our clients. We work closely with you to understand your needs and deliver bespoke solutions.

Q4: What materials does SourcifyChina use for stainless metal fabrication?

A4: We primarily use a variety of stainless steel grades, including 304, 316, and other specialty alloys, ensuring durability and corrosion resistance. Selection of material depends on the specific application and project requirements.

Q5: What is the typical lead time for a stainless metal fabrication project at SourcifyChina?

A5: Lead times vary depending on the complexity and scope of the project. However, we always aim to deliver within the agreed timelines and can provide expedited services if necessary. Please contact us for a precise estimate.

Q6: How can I get a quote for my stainless metal fabrication project?

A6: You can request a quote by visiting our website and filling out the inquiry form, or by contacting our sales team directly. Provide as much detail as possible about your project to ensure an accurate estimate.

Q7: Does SourcifyChina offer post-fabrication services such as assembly or shipping?

A7: Yes, we provide a full range of post-fabrication services, including assembly, packaging, and shipping, ensuring that your products are delivered ready-to-use and on time.

Q8: Are there any minimum order requirements for stainless metal fabrication at SourcifyChina?

A8: SourcifyChina can accommodate both small and large orders. However, minimum order quantities might apply depending on the complexity and requirements of the project. Contact us to discuss your specific needs.

Stainless steel fabrication is prevalent in various industries due to its durability, corrosion resistance, and aesthetic appeal. If you are considering working with a manufacturing partner like SourcifyChina factory for stainless metal fabrication, here are some valuable tips:

1. Define Specifications Clearly:

Ensure you have detailed specifications for your project, including dimensions, material grades, finishes, and tolerances. Clarity prevents misunderstandings and ensures precision.

2. Choose the Right Stainless Steel Grade:

Different grades, such as 304 or 316, offer varying levels of corrosion resistance and strength. Consult with SourcifyChina to select the most suitable grade for your application.

3. Design for Manufacturability:

Simplify designs to reduce complexity in welding and machining. This can help in minimizing costs and potential errors.

4. Surface Finishes:

Decide on the type of finish—be it brushed, mirror, or matte. Each finish has distinct characteristics and cost implications.

5. Prototyping:

Start with a prototype to validate the design and fabrication process. This step can identify potential issues early, saving time and money in the long run.

6. Quality Control:

Verify that SourcifyChina follows stringent quality control measures, including inspections and testing for weld integrity, dimensions, and surface finish.

7. Lead Times:

Discuss production timelines in detail. Factor in potential delays in material supply or manufacturing to better plan your project timeline.

8. Communication:

Maintain open communication channels with the factory. Regular updates can help address issues promptly and keep the project on track.

9. Check Compliance:

Ensure the factory complies with international standards and certifications pertinent to your industry. This guarantees the reliability and safety of your product.

10. Cost Assessment:

Request detailed quotes that include all costs—material, labor, shipping, and any additional services. Transparency helps in better budget management.

Working with a reputed partner like SourcifyChina can streamline your stainless metal fabrication project with exceptional quality and efficiency.

Sure, here is a list of Frequently Asked Questions (FAQ) with answers for sourcing stainless metal fabrication from SourcifyChina factory:

1. What services does SourcifyChina factory offer for stainless metal fabrication?

SourcifyChina provides a comprehensive range of services in stainless metal fabrication, including laser cutting, welding, bending, machining, and surface finishing. We cater to both small and large-scale production runs.

2. What materials can SourcifyChina work with?

SourcifyChina specializes in various grades of stainless steel but also has experience in working with other metals such as aluminum, carbon steel, and copper alloys.

3. How can I request a quote for my project?

To request a quote, you can upload your design files and project specifications directly on our website or send them via email. Include details such as material type, dimensions, quantities, and any special requirements.

4. What is the typical lead time for a project?

Lead times vary based on the complexity and volume of the project. However, standard lead times range from 2 to 6 weeks. We also offer expedited services for urgent projects.

5. Can SourcifyChina provide a sample before full production?

Yes, we can produce a prototype or sample for approval before proceeding with full-scale production to ensure it meets your specifications and quality standards.

6. What quality control measures are in place?

SourcifyChina implements strict quality control protocols, including material inspection, in-process quality checks, and final inspections with detailed reporting to ensure each product meets the highest standards.

7. What are the payment terms?

Our standard payment terms are 30% deposit upon order confirmation and the remaining 70% upon completion and prior to shipment. We also offer flexible payment options for bulk and repeat orders.

8. Do you provide after-sales support?

Yes, SourcifyChina offers comprehensive after-sales support, including troubleshooting, adjustments, and any necessary post-production modifications.

9. What are your shipping options?

We offer a variety of shipping options to meet your needs, including air freight, sea freight, and express courier services. We can also handle all export documentation and customs clearance.

10. How can I ensure the confidentiality of my design?

Sourcing stainless metal fabrication from SourcifyChina factory involves several key steps to ensure quality and reliability. Here are some tips:

1. Research and Identify Needs:

– Clarify your specifications including dimensions, material grade, tolerances, and finishing requirements.

– Determine your budget and production timelines.

2. Verify Factory Credentials:

– Check SourcifyChina’s certifications such as ISO 9001 for quality management.

– Look for reviews and testimonials from previous clients.

3. Initial Contact:

– Reach out via their official website or trusted sourcing platforms.

– Provide a detailed RFQ (Request for Quotation) with specs and quantities.

4. Sample Request:

– Ask for samples prior to bulk orders to assess quality.

– Evaluate the sample for adherence to your specifications and finish quality.

5. Audit the Facility:

– If possible, conduct a factory visit or hire a third-party inspection service.

– Assess their production capabilities, equipment, and workflow.

6. Quality Control:

– Establish clear quality control measures and agreements.

– Request regular production updates and quality check reports.

7. Negotiation:

– Negotiate pricing, payment terms, and delivery schedules.

– Ensure you understand Incoterms (FOB, CIF, etc.) for shipping.

8. Document Everything:

– Keep clear records of all agreements and communications.

– Ensure contracts outline all terms, including confidentiality clauses if necessary.

9. Shipping and Logistics:

– Arrange reliable logistics and understand customs regulations.

– Use tracking to monitor your shipment.

10. Build Relationship:

– Maintain open communication for future orders.

– Provide feedback to continuously improve product quality and service.

Following these steps will help you efficiently source high-quality stainless metal fabrication from SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.