Technology and Applications of stainless steel s

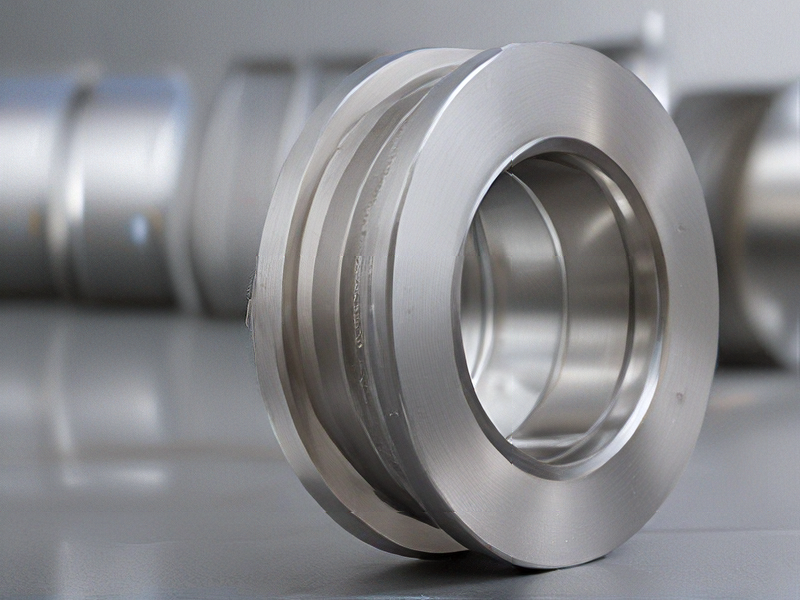

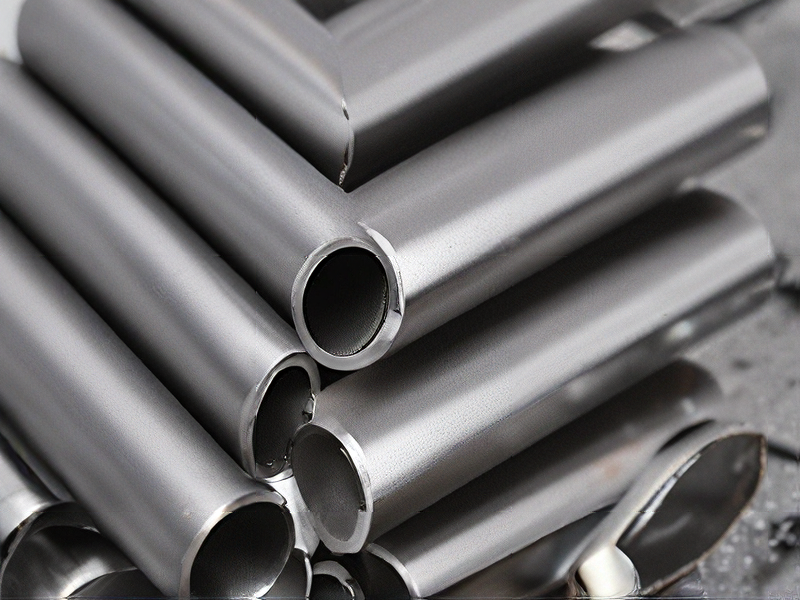

Stainless steel is an alloy primarily composed of iron, chromium, and often nickel, which provides exceptional corrosion resistance, durability, and aesthetic appeal. Its unique properties make it an ideal material for various applications across multiple industries.

One of the most common uses of stainless steel is in the food and beverage industry, where it is favored for its hygiene and ease of cleaning. Equipment like tanks, pipes, and processing machinery are often made from stainless steel to prevent contamination and maintain product quality.

In the medical field, stainless steel is invaluable due to its biocompatibility and resistance to corrosion. Surgical instruments, implants, and hospital equipment utilize stainless steel to ensure safety and reliability in sterile environments.

Architecture and construction also benefit from stainless steel, which is used in facades, structural components, and interior design fixtures. Its strength and aesthetic versatility allow for innovative designs while ensuring longevity and minimal maintenance.

In the automotive and aerospace sectors, stainless steel components are employed to enhance performance and reduce weight without sacrificing durability. This is vital for improving fuel efficiency and safety.

Furthermore, with the rise of renewable energy technologies, stainless steel is increasingly used in solar panels and wind turbines due to its resistance to harsh environmental conditions.

Overall, the technology and applications of stainless steel are vast and varied, making it a cornerstone material in modern engineering and design. Its unique properties not only enhance functional performance but also contribute to sustainability by promoting recycling and reducing the lifecycle impact of products.

Quality Testing Methods for stainless steel s and how to control quality

Quality testing methods for stainless steel are crucial to ensure it meets mechanical, chemical, and physical standards. The following are key methods and quality control strategies:

1. Visual Inspection: Initial assessments involve examining the surface for defects like cracks, pits, or inconsistencies. This technique is quick and non-destructive.

2. Mechanical Testing:

– Tensile Testing measures strength, elongation, and yield point.

– Hardness Testing (Rockwell, Brinell) evaluates material hardness, which is vital for wear resistance.

– Impact Testing determines toughness and how materials behave under sudden loads.

3. Chemical Analysis: Techniques like spectrometry or X-ray fluorescence (XRF) identify the elemental composition of stainless steel, ensuring compliance with specifications such as ASTM or ISO standards.

4. Corrosion Resistance Testing: The Ferric Chloride Test or Salt Spray Test simulates corrosive environments to assess the material’s resistance to pitting and crevice corrosion.

5. Non-destructive Testing (NDT): Methods such as ultrasonic testing (UT) and radiographic testing (RT) help detect internal flaws without damaging the material.

Quality Control Strategies

– Standard Operating Procedures (SOPs): Establish clear guidelines for testing methods and frequency.

– Calibration and Maintenance: Regularly calibrate equipment to ensure accurate measurements.

– Training Personnel: Continuously train quality control staff on the latest testing techniques and standards.

– Documentation and Traceability: Maintain detailed records of test results and procedures for accountability and traceability.

– Supplier Quality Management: Assess and routinely audit suppliers to ensure raw materials meet quality requirements.

Implementing these methods and strategies bolsters the integrity and performance of stainless steel in various applications.

Tips for Procurement and Considerations when Purchasing from stainless steel s

When procuring stainless steel, consider the following tips and key factors to ensure that you make informed purchasing decisions:

1. Material Grades: Identify which stainless steel grade suits your application. Common grades include 304 (general-purpose) and 316 (corrosive environments). Each grade offers different properties such as corrosion resistance, tensile strength, and formability.

2. Supplier Reputation: Choose suppliers with a proven track record and positive reviews. Verify their certifications and compliance with industry standards, ensuring they meet quality requirements.

3. Cost vs. Quality: While budget is important, prioritize quality to avoid future expenses related to corrosion or failure. Compare prices among suppliers but be wary of unusually low bids.

4. Specifications and Standards: Ensure that the stainless steel complies with necessary specifications, such as ASTM standards, which ensure consistency and quality.

5. Finish and Treatment: Different finishes (e.g., brushed, polished) affect aesthetics and performance. Select a finish suitable for your application, considering factors such as maintenance and exposure to elements.

6. Supply Chain and Logistics: Evaluate the supplier’s ability to deliver on time and their logistics capabilities. Consistent delivery schedules are crucial for project timelines.

7. Customization and Fabrication: Determine if you need custom fabrication services. A supplier who offers cutting, welding, or coating can reduce project lead times.

8. Sustainability and Scrap Value: Consider suppliers that prioritize sustainability. Stainless steel has a high scrap value, making it an eco-friendly choice if sourced from responsible suppliers.

By carefully considering these factors, you can make a more informed decision and choose the right stainless steel products for your needs.

FAQs on Sourcing and Manufacturing from stainless steel s in China

FAQs on Sourcing and Manufacturing Stainless Steel in China

Q1: Why source stainless steel products from China?

A1: China is a leading manufacturer due to its competitive pricing, vast production capabilities, and access to advanced technologies. This allows businesses to achieve cost-effective sourcing without compromising quality.

Q2: What types of stainless steel products can I source?

A2: You can source a wide range of products including kitchenware, industrial components, medical instruments, and custom fabrication items, all made from various grades of stainless steel.

Q3: How do I find reliable manufacturers?

A3: Utilize platforms like Alibaba, Global Sources, or trade shows. Check reviews, request samples, and verify company credentials through third-party audits or industry certifications.

Q4: What are the key factors to consider during sourcing?

A4: Consider the manufacturer’s reputation, production capacity, quality control measures, compliance with international standards, lead times, and communication capabilities.

Q5: How can I ensure product quality?

A5: Implement a robust quality assurance process, including pre-production samples, in-process inspections, and final random inspections. Certifications like ISO 9001 can also indicate adherence to quality standards.

Q6: What are the typical payment terms?

A6: Payment terms vary, but a common practice is 30% upfront and 70% before shipment. Always discuss and agree on terms in advance to avoid misunderstandings.

Q7: What is the lead time for manufacturing?

A7: Lead times can range from a few weeks to several months depending on order size, complexity, and the manufacturer’s production schedule. Always confirm estimated lead times before placing orders.

Q8: Are there import duties for stainless steel products?

A8: Yes, import duties vary by country and product type. Check with local customs regulations to understand applicable tariffs before sourcing.