Choosing SourcifyChina for stainless steel sheet fabrication ensures quality and reliability. Located in China, they leverage advanced technology and rigorous quality control methods to deliver superior products.

Their experienced team guarantees precise fabrication, catering to various industrial needs. Competitive pricing combined with excellent customer service makes them an ideal choice.

Moreover, SourcifyChina’s efficient supply chain and strategic location enable timely delivery, reducing lead times. Their commitment to sustainability ensures environmentally responsible production processes, aligning with global standards.

With a strong reputation for customer satisfaction and continuous improvement, SourcifyChina stands out. Partnering with them promises not only high-quality products but also a seamless, trustworthy purchasing experience.

Stainless steel sheet fabrication offers diverse methods for shaping and manipulating stainless steel sheets into desired forms. Key techniques include laser cutting, bending, welding, and finishing, each suited for various applications and project requirements.

– Laser Cutting: Precision cutting with minimal waste

– Plasma Cutting: Cost-effective for thicker sheets

– Water Jet Cutting: Accurate cutting without heat distortion

– Bending: CNC press brakes for precise angles

– Welding: TIG, MIG, and spot welding for strong joints

– Finishing: Polishing, brushing, and coating for aesthetics and protection

– Punching: Creating holes or shapes via mechanical presses

– Shearing: Straight cuts with high precision

Stainless steel sheet fabrication finds extensive applications across various industries due to its durability, resistance to corrosion, and aesthetic appeal. It is utilized in:

– Construction: Architectural panels, cladding, roofing, and structural components.

– Medical: Surgical instruments, hospital equipment, and laboratory benches.

– Food and Beverage: Processing equipment, storage tanks, and kitchenware.

– Automotive: Body panels, exhaust systems, and trim.

– Energy: Offshore platforms, power plant components, and pipelines.

– Chemical: Reactors, containment vessels, and piping.

– Aerospace: Aircraft parts, engine components, and heat shields.

– Marine: Boat fittings, shipbuilding materials, and marine hardware.

– Domestic Appliances: Ovens, refrigerators, dishwashers, and washing machines.

– Heavy Machinery: Conveyor belts, support structures, and industrial machines.

– Art and Design: Sculptures, installations, and decorative elements.

– Pharmaceutical: Cleanroom surfaces, mixing tanks, and bioprocessing equipment.

– Electronics: Enclosures, circuit board supports, and casings.

– Signage: Commercial signs, nameplates, and advertising hoardings.

– HVAC: Ductwork, air handling units, and ventilation systems.

– Water Treatment: Tanks, filters, and desalination units.

– Renewable Energy: Solar panel frames, wind turbine components, and biofuel equipment.

These various applications underscore the versatility and importance of stainless steel sheet fabrication in modern engineering and design.

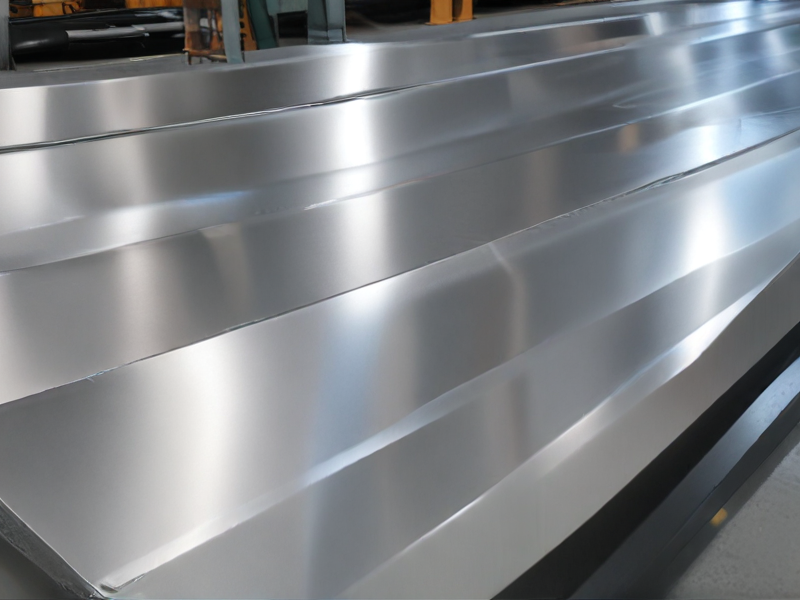

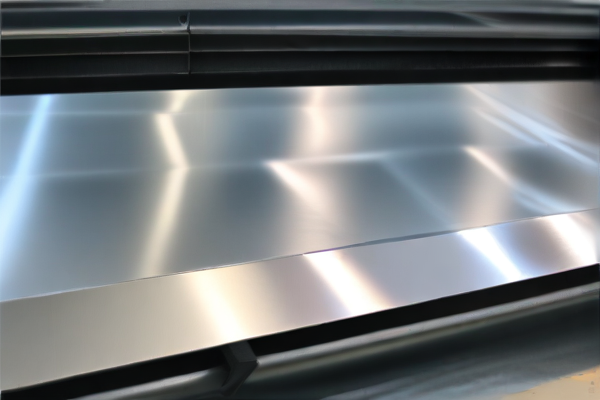

SourcifyChina specializes in stainless steel sheet fabrication, delivering high-quality sheets suitable for numerous applications. They offer durability, corrosion resistance, and aesthetic appeal, making them ideal for construction and industrial projects.

Utilizing advanced technology, SourcifyChina ensures precision in cutting, bending, and forming steel sheets to meet exact specifications. Their commitment to quality and innovation sets them apart in the industry, providing reliable and efficient services.

SourcifyChina sources premium-grade stainless steel, guaranteeing consistent performance and longevity. This commitment to quality materials is a testament to their dedication to customer satisfaction and trust.

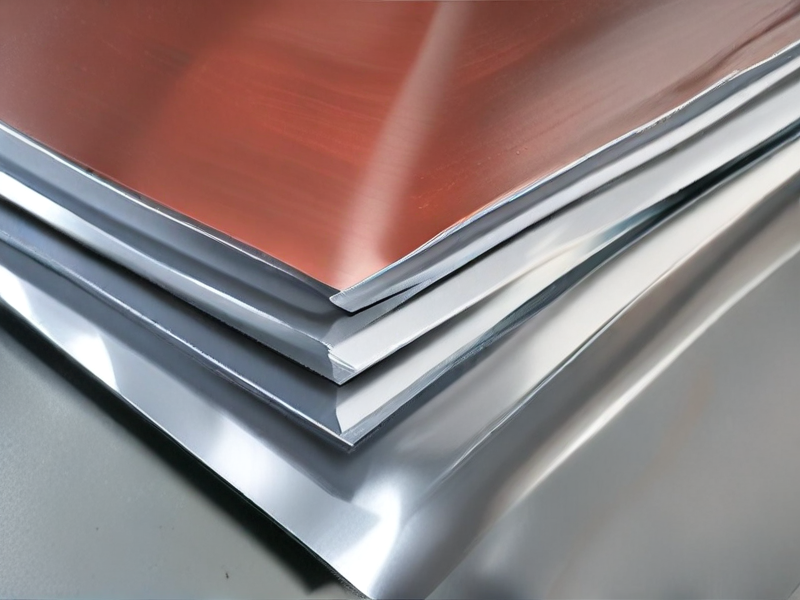

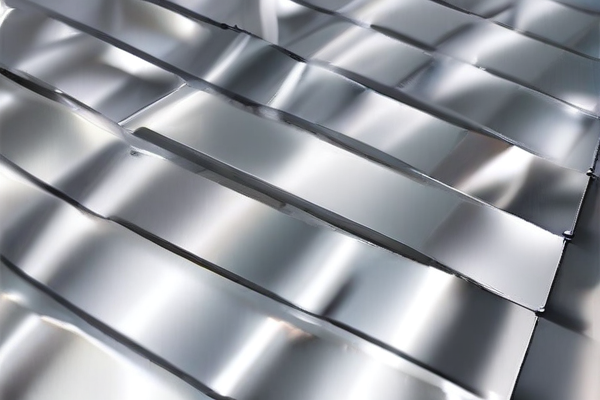

The company offers various finishes, from brushed to polished, catering to different project needs and design preferences. Their adaptable solutions make them a preferred choice for architects and engineers alike.

In addition to standard products, SourcifyChina provides custom fabrication services, allowing for unique and specialized designs. Their expert team works closely with clients to ensure each project is executed flawlessly and within budget.

With a strong focus on sustainability, SourcifyChina uses environmentally friendly practices in their fabrication processes. They aim to minimize waste and energy consumption, contributing positively to the environment.

SourcifyChina’s stainless steel sheets undergo rigorous testing to meet industry standards and client requirements. This dedication to excellence ensures that every sheet performs optimally under various conditions and applications.

Their customer support team is readily available to address inquiries and provide guidance throughout the fabrication process. This fosters seamless communication and project management, contributing to a smooth and satisfactory experience.

SourcifyChina’s commitment to quality, innovation, and customer satisfaction makes them a leader in stainless steel sheet fabrication. Their adaptability and expert services position them as a trusted partner for both standard and custom projects. With a focus on durability and precision, they continue to set benchmarks in the industry.

SourcifyChina employs rigorous quality control measures in its stainless steel sheet fabrication process. The journey begins with the careful selection of raw materials, ensuring they meet international standards for durability and performance.

The next step is precision cutting, which utilizes advanced machinery to achieve exact dimensions. This precision is crucial for the consistency and reliability of the final product. Laser cutting and CNC machinery are often employed to ensure high standards are met.

Following cutting, sheets undergo various forming processes, such as bending and rolling. At each stage, skilled technicians and automated systems inspect the sheets for flaws, monitoring for quality deviations.

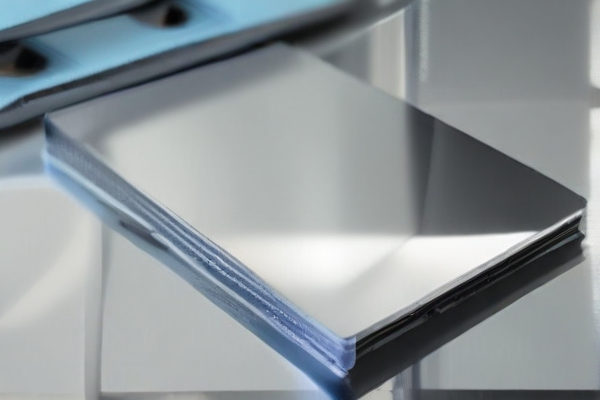

Welding and assembly come next, requiring meticulous skill and precision. Automated welding systems are calibrated to the highest standards, while human oversight ensures that all joints are secure and stable.

The final inspection phase involves comprehensive testing, including stress tests and surface inspections. These tests confirm that the stainless steel sheets meet both internal and customer-specific requirements for strength, durability, and finish.

A stringent documentation process ensures traceability throughout the manufacturing process. Records are kept of every batch, allowing for easy identification of any issues or deviations from standards.

Achieving ISO certification further solidifies the commitment to quality. This certification ensures that each process adheres to globally recognized standards, giving customers peace of mind about the reliability of the product.

Customer feedback is another critical component. Post-delivery, feedback is actively sought to identify any areas for improvement. Continuous training for the workforce ensures that they stay updated with the latest best practices and technologies.

SourcifyChina’s dedication to quality control in stainless steel sheet fabrication encompasses every stage from raw material selection to final inspection. With meticulous attention to detail, advanced technology, and a commitment to continuous improvement, they ensure that every product meets the highest standards. This approach not only meets but often exceeds customer expectations, affirming their reputation as a leader in the industry.

SourcifyChina is renowned for its advanced stainless steel sheet fabrication capabilities. Leveraging state-of-the-art machinery and technology, the company ensures high precision and superior quality in every project.

The firm offers a wide range of services, including laser cutting, welding, and CNC machining, tailored to meet the diverse needs of various industries. Automated processes enhance both efficiency and consistency.

SourcifyChina employs a team of skilled professionals dedicated to maintaining stringent quality control standards. This ensures that each fabricated product meets or exceeds client expectations and industry regulations.

Their robust supply chain management ensures timely delivery, supported by a seamless logistics network. The company’s commitment to sustainability is reflected in its eco-friendly practices and material sourcing.

Client collaboration is a cornerstone of SourcifyChina’s operations. Through open communication and customized solutions, the company ensures optimal results for every project. This client-centric approach fosters long-lasting relationships and ongoing success.

By combining cutting-edge technology, expert craftsmanship, and sustainable practices, SourcifyChina continues to lead in stainless steel sheet fabrication. Their unwavering commitment to quality and customer satisfaction makes them a trusted partner in this highly competitive industry.

Stainless steel sheet fabrication offers an array of benefits that make it a preferred choice in various industries, including construction, automotive, and medical equipment manufacturing.

– Durability: Stainless steel is highly resistant to corrosion, rust, and staining, ensuring long-lasting products.

– Strength: Its high tensile strength and toughness make it ideal for heavy-duty applications.

– Aesthetic Appeal: Stainless steel provides a sleek, modern look that enhances the visual appeal of products.

– Hygienic Properties: The non-porous surface of stainless steel is easy to clean and sanitize, crucial for medical and food industries.

– Recyclability: Stainless steel is 100% recyclable, making it an eco-friendly choice.

– Thermal Resistance: It can withstand extreme temperatures without deforming, suitable for various industrial applications.

– Low Maintenance: Requires minimal upkeep, reducing long-term costs.

– Versatility: Suitable for a wide range of fabrication techniques, from welding to cutting, allowing for diverse design possibilities.

Stainless steel sheet fabrication boasts various features, making it a versatile material in many industries, including construction, automotive, and appliances.

– Corrosion Resistance: One of the primary advantages is its resistance to rust and corrosion, ensuring durability.

– Strength and Durability: Stainless steel sheets offer excellent strength-to-weight ratios, making them ideal for structural and load-bearing applications.

– Aesthetic Appeal: With a shiny, modern finish, stainless steel sheets add a sleek look to products and structures.

– Heat Resistance: These sheets can withstand high temperatures without losing integrity.

– Workability: Stainless steel is highly malleable and can be easily cut, welded, and shaped to meet specific design needs.

– Hygiene: The non-porous surface of stainless steel is easy to clean and sterilize, making it suitable for food and medical applications.

– Recyclability: Stainless steel is 100% recyclable, contributing to sustainable building practices.

– Low Maintenance: Requires minimal upkeep to retain its appearance and properties over time.

– Cost-Effectiveness: While initially more expensive, its long lifespan often results in cost savings.

– Customization: Can be manufactured in various thicknesses and finishes, meeting diverse project requirements.

– Magnetic Properties: Available in both magnetic and non-magnetic options, depending on the alloy used.

– Weldability: Advanced welding techniques can be applied to stainless steel sheets without compromising the material’s structural integrity.

These features collectively make stainless steel sheets a preferred choice for a broad range of applications, ensuring performance, longevity, and aesthetic appeal.

SourcifyChina specializes in creating custom stainless steel sheet fabrication products tailored to meet diverse industry needs. Their expertise extends across various sectors, delivering precise and high-quality solutions. From intricate machinery components to sleek architectural elements, their fabricated products ensure durability and aesthetic appeal.

Employing advanced technology and skilled craftsmanship, SourcifyChina ensures each product meets rigorous standards. The company’s commitment to excellence is evident in the consistent quality and meticulous attention to detail, making them a trusted partner for enterprises seeking reliable stainless steel components.

SourcifyChina’s project portfolio is extensive, spanning from simple brackets to complex engineering assemblies. Each project is handled with a personalized approach, guaranteeing that client specifications are met with precision. Their capable team manages everything from initial design to final installation.

Through collaboration and innovation, SourcifyChina continues to push the boundaries in stainless steel fabrication. Their focus on customer satisfaction and continuous improvement cements their reputation in the market. Whether for industrial use or artistic applications, their custom solutions elevate functionality and style.

In summary, SourcifyChina’s stainless steel sheet fabrication services stand out for their superior quality, tailored solutions, and comprehensive project management. They remain a go-to source for businesses needing reliable and custom metal fabrication expertise.

SourcifyChina Stainless Steel Sheet Fabrication stands out as a premier provider of high-quality stainless steel sheet solutions, catering to a diverse range of industries worldwide. Renowned for their commitment to precision engineering and exceptional craftsmanship, the company leverages state-of-the-art technology and advanced machinery to deliver products that meet stringent international standards. From initial design consultation to final production, SourcifyChina ensures each project is tailored to the unique specifications and needs of their clients. This meticulous attention to detail, coupled with a robust quality control process, guarantees that every stainless steel sheet produced is of unparalleled durability and finish. Comprising a team of skilled professionals with extensive industry experience, SourcifyChina prides itself on its ability to offer innovative and cost-effective solutions, ensuring timely delivery and complete client satisfaction. Whether serving the needs of the automotive, construction, or aerospace sectors, SourcifyChina remains a trusted partner for those seeking reliable and superior stainless steel fabrication services.

Stainless steel sheet fabrication plays a critical role in the aerospace, defense, and marine industries due to its exceptional strength, corrosion resistance, and versatility. For aerospace applications, stainless steel sheets are utilized in the construction of various aircraft components such as fuselage skins, engine parts, and landing gear structures. The material’s ability to withstand extreme temperatures and its high tensile strength make it ideal for ensuring the durability and safety of aircraft. Additionally, the non-corrosive properties of stainless steel help protect critical parts from the harsh conditions encountered at high altitudes and during high-speed flights, thus prolonging the lifespan and reliability of aerospace components.

In the defense and marine sectors, stainless steel sheet fabrication is essential for building robust and reliable machinery and structures. Defense applications include the manufacturing of armored vehicles, weaponry, and military infrastructure, where the material’s durability and resistance to wear are paramount. In the marine industry, stainless steel sheets are integral in the construction of ship hulls, decks, and underwater pipelines. The alloy’s resistance to seawater corrosion and biofouling ensures that marine vessels and structures maintain their integrity and functionality over extended periods. Moreover, the ease of fabrication and welding of stainless steel sheets allows for custom designs and repairs, facilitating the construction of specialized defense and marine equipment tailored to specific operational needs.

Stainless steel sheet fabrication plays an integral role in the automotive industry, offering a blend of durability, strength, and aesthetic appeal. Automotive manufacturers leverage this versatile metal to produce crucial components such as body panels, frames, exhaust systems, and trim. The corrosion resistance of stainless steel ensures longevity and reduced maintenance, which is particularly beneficial in environments exposed to harsh weather conditions and road salts. Additionally, the ability to form complex shapes and designs through advanced fabrication techniques allows for innovation in vehicle design, enhancing both performance and safety. The lower weight of certain stainless steel alloys also contributes to improved fuel efficiency, aligning with the industry’s push towards more sustainable practices.

In the realm of electronics, stainless steel sheet fabrication is equally significant. It is frequently used in the creation of enclosures, casings, and internal structural components for a variety of electronic devices. The non-corrosive nature of stainless steel protects sensitive electronic parts from environmental damage, thereby prolonging device lifespan. Its superior thermal and electrical conductivity is advantageous in managing heat dissipation in high-performance computers, smartphones, and other electronic gadgets. Additionally, the sleek, polished finish of fabricated stainless steel is not only functional but also adds a premium aesthetic quality to consumer electronics. With its robustness, ease of sterilization, and resilience against wear, stainless steel remains a material of choice in fabricating medical electronics and equipment where hygiene is of utmost importance.

Stainless steel sheet fabrication plays a pivotal role in the construction industry due to its durability, corrosion resistance, and aesthetic appeal. In building structures, stainless steel sheets are utilized for forming facades, roofing, and cladding that not only enhance the visual impact but also provide longevity and reduced maintenance requirements. The material’s ability to withstand extreme weather conditions and its resistance to rust make it an ideal choice for exterior applications. Additionally, its inherent strength and flexibility allow it to be crafted into various shapes and sizes, catering to innovative architectural designs. Interior applications in construction, such as kitchen countertops, backsplashes, and custom fixtures, benefit from stainless steel’s hygienic properties and ease of cleaning, creating environments that are both functional and visually appealing.

In the energy sector, stainless steel sheet fabrication is crucial for developing equipment and infrastructure that can endure harsh operational conditions. For instance, in renewable energy applications like wind turbines and solar panels, stainless steel components ensure structural integrity and long-term performance despite exposure to the elements. In the oil and gas industry, stainless steel’s ability to resist corrosion from chemicals and saline environments makes it indispensable for constructing pipelines, storage tanks, and refineries. The material’s thermal resistance is equally important in high-temperature environments such as power plants and energy generation facilities, where it is used in heat exchangers, boilers, and various other components. Thus, the fabrication of stainless steel sheets not only improves efficiency and safety in energy production but also contributes to the overall reliability and sustainability of energy infrastructure.

The industrial equipment industry extensively utilizes stainless steel sheet fabrication due to its remarkable durability, resistance to corrosion, and ease of maintenance. Stainless steel sheets are crucial for manufacturing a wide array of industrial equipment including tanks, pipelines, conveyors, and heavy machinery. Given its resistance to extreme temperatures and chemical interactions, stainless steel becomes an ideal material for equipment used in harsh environments such as chemical processing plants, oil refineries, and food processing units. The fabrication process involves cutting, welding, bending, and assembling the stainless steel sheets to form the desired components, ensuring precision and strength in the final products. These processes are often performed using advanced technologies such as CNC machines and laser cutters, which provide high accuracy and efficiency.

Moreover, stainless steel sheet fabrication supports the customization of industrial equipment, meeting specific requirements and standards for different sectors. This adaptability is particularly beneficial as industries continuously evolve and demand specialized equipment for optimized performance and productivity. For instance, in the pharmaceutical industry, stringent hygiene standards necessitate equipment that is not only robust but also easy to sterilize. Stainless steel’s smooth surface and non-porous nature make it perfect for such applications. Additionally, the recyclability of stainless steel aligns with growing environmental concerns, contributing to sustainable manufacturing practices in the industrial equipment sector. Overall, the use of stainless steel sheet fabrication is instrumental in producing reliable, high-quality industrial equipment that caters to the rigorous demands of various industries.

Stainless steel sheet fabrication plays a pivotal role in the manufacture of medical devices, delivering precision, durability, and hygiene essential for the healthcare industry. Stainless steel, especially grades like 304 and 316L, is widely used because of its excellent resistance to corrosion, ease of sterilization, and superior mechanical properties. The fabrication process involves cutting, bending, forming, and welding stainless steel sheets to create various intricate components, including surgical instruments, orthopedic implants, and medical device housings. For example, surgical instruments made from stainless steel are highly durable, maintain a sharp edge, and can undergo repeated sterilization cycles without degradation. Similarly, orthopedic implants benefit from the alloy’s biocompatibility and mechanical strength, ensuring that devices such as bone plates and screws perform reliably within the human body.

Moreover, stainless steel sheet fabrication supports the development of complex and customized medical devices through advanced techniques such as laser cutting and CNC machining. These processes enable high precision and consistency, crucial for producing intricate components that meet stringent regulatory standards. Precision fabrication ensures that devices fit seamlessly within existing medical systems and with other device components, enhancing the overall efficacy and safety of medical treatments. Additionally, the non-porous surface of stainless steel sheets discourages bacterial growth, which is vital for maintaining sterility in medical environments. The adaptability of stainless steel sheet fabrication makes it indispensable in crafting a wide array of life-saving medical devices, underscoring its essential role in modern healthcare technology.

Stainless steel sheet fabrication is pivotal in the realm of machining and manufacturing due to its exceptional properties and versatility. The process involves cutting, bending, forming, and assembling stainless steel sheets into various products and components, leveraging the material’s remarkable resistance to corrosion, aesthetic appeal, and durability. Techniques such as laser cutting, waterjet cutting, and CNC machining provide precision and efficiency, ensuring intricate designs and high-quality finishes. Businesses across sectors such as automotive, aerospace, food processing, and medical device manufacturing rely heavily on stainless steel sheet fabrication for both functional and decorative purposes, underscoring its indispensable role in modern industry.

In manufacturing applications, stainless steel sheet fabrication is not only about creating durable products but also enhancing efficiency and cost-effectiveness. Advanced technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM) streamline the process, reducing lead times and minimizing material waste. The recyclability of stainless steel further supports sustainable manufacturing practices, meeting the growing demand for eco-friendly production. Additionally, the non-reactive nature of stainless steel makes it ideal for critical environments where sanitation and hygiene are paramount, such as in pharmaceutical and food industries. This combination of technological advancements, material properties, and environmental considerations makes stainless steel sheet fabrication a cornerstone of contemporary manufacturing.

Certainly! Here are some frequently asked questions (FAQ) about the manufacturing of stainless steel sheet fabrication quality work from SourcifyChina factory with answers:

Q: What types of stainless steel sheets do you fabricate?

A: SourcifyChina fabricates a variety of stainless steel sheets including 304, 316, and 430 grades, ensuring high-quality and corrosion-resistant materials.

Q: What are your quality control measures?

A: We employ rigorous quality control measures that include material verification, dimensional inspection, surface finish assessment, and compliance with international standards such as ISO 9001.

Q: Do you provide custom fabrication services?

A: Yes, SourcifyChina offers custom fabrication services tailored to your specifications, including cutting, bending, welding, and finishing.

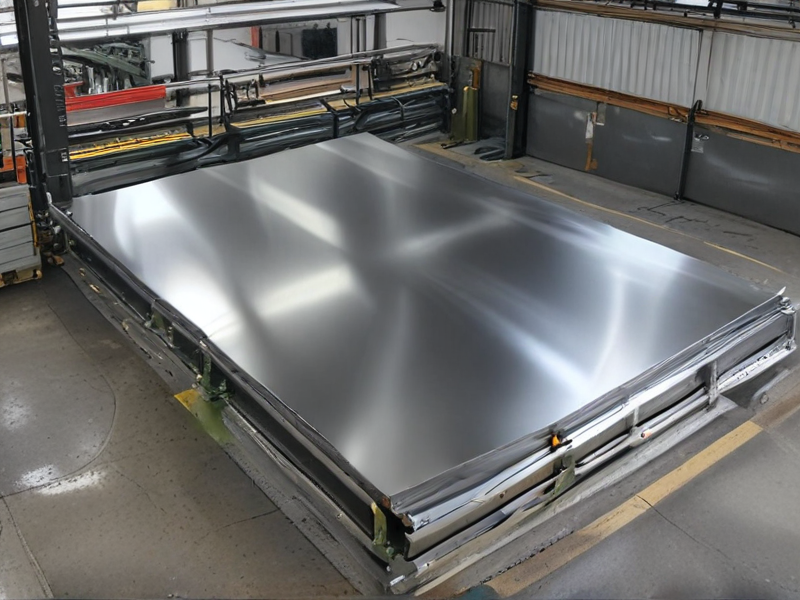

Q: What is the maximum sheet size you can handle?

A: We can handle stainless steel sheets up to a size of 3000mm x 1500mm, but custom sizes can also be accommodated upon request.

Q: Can you provide surface finishing options?

A: Absolutely, we offer a range of surface finishes including mill finish, brushed, mirror, and electro-polished finishes to meet your aesthetic and functional requirements.

Q: How long does production usually take?

A: Lead times vary depending on the complexity and volume of the order but generally range from 2 to 6 weeks.

Q: Do you offer prototyping services?

A: Yes, we provide rapid prototyping services to help you visualize and refine your product before full-scale production.

Q: What are your pricing terms?

A: Our pricing is competitive and depends on the material, complexity, and volume of the order. We offer both FOB and CIF terms.

Q: How do you ensure the durability of fabricated stainless steel sheets?

A: We use high-quality raw materials and adhere to stringent manufacturing practices to ensure long-lasting and durable products.

Q: Can you assist with design and engineering support?

A: Yes, our experienced team provides comprehensive design and engineering support to optimize your product for manufacturability and performance.

Q: Are there any minimum order quantities (MOQs)?

A: While we are flexible with order quantities, certain projects may have MOQs based on the complexity and material requirements. Please contact us for specific details.

Q: How do I get a quote for my project?

Stainless steel sheet fabrication is a specialized process that transforms raw materials into precise components for various industries. When collaborating with a reputable factory like SourcifyChina, consider the following tips:

Choose the right grade of stainless steel tailored to your specific application. Common grades include 304 for general use and 316 for higher corrosion resistance.

Ensure that the factory employs advanced machinery such as CNC lasers and presses for cutting, bending, and shaping to achieve high precision and minimize waste.

Discuss finishing options like polishing, brushing, or coating to enhance durability and aesthetic appeal. SourcifyChina offers various finishes to meet your needs.

Look for stringent quality control measures. SourcifyChina typically implements rigorous inspections at each stage of fabrication to ensure the highest quality.

Collaborate closely with their design team for custom solutions. Detailed technical drawings and prototypes are essential for meeting exact specifications.

Take advantage of SourcifyChina’s competitive pricing without compromising on quality. Bulk orders often come with discounts, reducing overall costs.

Clarify lead times upfront. Efficient workflow management at SourcifyChina ensures timely delivery, crucial for maintaining your project schedule.

Ensure the factory complies with international standards and certifications. SourcifyChina’s adherence to ISO and other relevant standards guarantees reliable performance and safety.

Maintain clear and consistent communication. Use project management tools for tracking progress, addressing concerns, and making adjustments as needed.

Check the availability of after-sales support. SourcifyChina provides ongoing assistance post-delivery, ensuring any issues are promptly resolved.

By considering these factors, you can effectively leverage SourcifyChina’s capabilities to achieve superior stainless steel sheet fabrication.

Certainly! Here is a list of frequently asked questions (FAQ) along with their answers for sourcing stainless steel sheet fabrication from SourcifyChina factory:

Q1: What types of stainless steel sheet grades do you offer?

A1: SourcifyChina offers a variety of stainless steel grades including 304, 316, 430, and more. Please contact us for specific grade availability and recommendations based on your project needs.

Q2: What is the minimum order quantity (MOQ) for stainless steel sheet fabrication?

A2: The MOQ for custom stainless steel sheet fabrication varies depending on the complexity of the design and the specific grade used. Typically, it starts from 100 sheets.

Q3: What is the typical turnaround time for an order?

A3: Standard lead time is usually 4-6 weeks. However, it can vary depending on order size, design complexity, and current factory workload. Expedited services may be available upon request.

Q4: Do you provide prototyping services before mass production?

A4: Yes, SourcifyChina offers prototyping services to ensure the design meets your requirements before moving on to mass production. Additional costs and lead time may apply for prototyping.

Q5: What are the tolerances for stainless steel sheet fabrication?

A5: Tolerances depend on the specific fabrication processes used. Generally, we adhere to industry standards but can also meet custom tolerance requirements upon request.

Q6: Can you provide surface finishes and coatings?

A6: Yes, we offer a variety of surface finishes including brushed, mirror, and satin finishes, as well as coating options like powder coating and anodizing.

Q7: How do you ensure quality and consistency in your products?

A7: SourcifyChina implements strict quality control measures including material verification, in-process inspections, and final quality checks to ensure every product meets our high standards.

Q8: What payment methods do you accept?

A8: We accept various payment methods including wire transfers, letters of credit, and PayPal. Terms and conditions apply based on the agreement.

Q9: How can I request a quote?

A9: You can request a quote by visiting our website and filling out the quote request form or by contacting our sales team directly via email or phone.

Q10: Do you provide shipping services?

Sourcing stainless steel sheet fabrication from SourcifyChina factory can be an efficient way to meet your production needs cost-effectively. Here are some tips to make the process smoother:

1. Clear Requirements: Define your specifications thoroughly. Include details like type of stainless steel, thickness, dimensions, surface finish, and any fabrication processes (cutting, bending, welding, etc.).

2. Request Quotes: Contact SourcifyChina directly or use their platform to request a quote. Provide comprehensive information to get accurate pricing.

3. Check Capabilities: Ensure the factory has the capabilities and experience required. Look at past projects, ask for samples, and verify they can meet your quality standards.

4. Quality Assurance: Discuss their quality control processes. Align on inspection criteria, testing methods, and acceptable tolerances before production begins.

5. Lead Times: Clarify production and shipping timelines upfront. Make sure the factory can meet your deadlines to avoid project delays.

6. Communication: Maintain open and regular communication. Designate a point of contact and use clear, concise messaging to avoid misunderstandings.

7. Bulk Orders: Inquire about discounts for large orders. Discuss batch production capabilities, which can also reduce manufacturing costs.

8. Payment Terms: Negotiate payment terms that are mutually beneficial. Consider splitting payments to manage risk (e.g., 30% upfront, 70% upon delivery).

9. Logistics: Plan for shipping and customs. Work with a reliable freight forwarder to handle import duties and ensure timely delivery.

10. Sustainability: If important for your brand, check the factory’s adherence to environmental standards and certifications.

By following these tips, you can efficiently source high-quality stainless steel sheet fabrication from SourcifyChina, ensuring your project runs smoothly from start to finish.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.