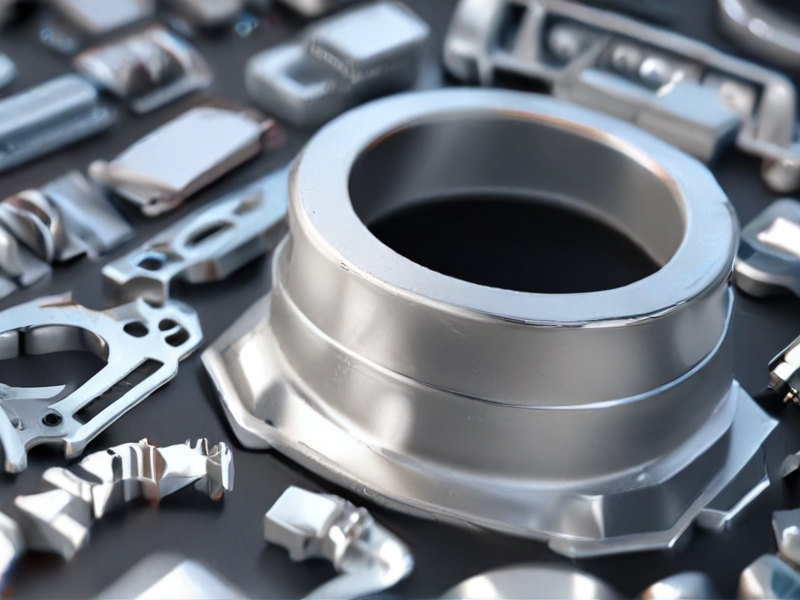

Finding Reliable Suppliers: SourcifyChina Connects You with Top-Quality Factory Stamping Parts Manufacturers in China for Efficient and Cost-Effective Production

If you’re searching for dependable manufacturers for your stamping parts, SourcifyChina is your go-to platform, partnering you with the best factory suppliers in China to ensure quality and efficiency in your production process.

Choosing SourcifyChina Factory for purchasing stamping parts from China offers unmatched quality, reliability, and pricing. Our factory ensures that each product meets stringent international standards, ensuring your peace of mind.

Our experienced team of professionals exercises rigorous quality control at every production stage. This commitment to excellence ensures that our stamping parts exceed your expectations.

SourcifyChina Factory is strategically located, providing swift production and efficient logistics services. Leveraging China’s robust manufacturing ecosystem allows us to offer competitive prices without compromising quality.

Customer satisfaction is the cornerstone of our business philosophy. We offer personalized service and dedicated support from order placement to delivery, ensuring a seamless purchasing experience.

In summary, SourcifyChina Factory is your go-to partner for high-quality, cost-effective stamping parts. Our commitment to excellence, strategic location, and customer-centric approach make us the ideal choice.

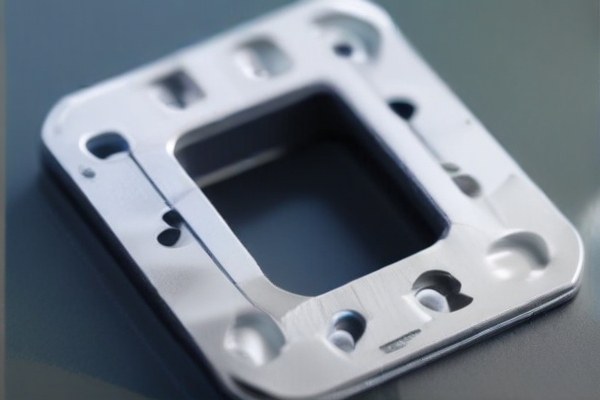

Stamping parts suppliers offer various options, including progressive die stamping, single-hit stamping, and transfer stamping. These processes accommodate different part complexities, materials, and production volumes to meet specific industry needs.

– Progressive Die Stamping: Uses a series of dies in one machine to progressively shape the part, ideal for high-volume production.

– Single-Hit Stamping: Involves one die operation per machine cycle, suitable for low- to medium-volume and complex parts.

– Transfer Stamping: Moves the part through multiple stations, each performing a different operation, perfect for large, intricate parts.

– Materials: Suppliers work with steel, aluminum, copper, and more.

– Customization: Tailored solutions for automotive, electronics, aerospace, and other industries.

– Quality Assurance: Advanced inspection methods to ensure precision and consistency.

– Prototyping: Rapid development of prototypes for testing and evaluation before full-scale production.

– Cost Optimization: Efficient processes designed to reduce material waste and production costs.

– Lead Times: Vary based on project complexity and volume, generally ranging from a few weeks to several months.

– Technology: Utilization of modern technology like CNC machines and automation for enhanced precision and efficiency.

– Supplier Certifications: Look for ISO 9001, IATF 16949, or other relevant certifications ensuring quality and reliability.

– Geographical Location: Local versus international suppliers, impacts shipping costs and lead times.

– Customer Support: Comprehensive support from design consultation to post-production services.

Choosing the right stamping supplier involves evaluating these factors to ensure they align with your project requirements and standards.

Stamping parts suppliers provide essential components for various industries, ensuring precision and reliability through advanced manufacturing techniques. Their capabilities include a wide range of applications tailored to meet specific requirements.

– Automotive Industry: Production of body panels, brackets, and interior components.

– Electronics: Creation of connectors, heat sinks, and shielding components.

– Aerospace: Manufacturing of lightweight, high-strength parts for aircraft.

– Medical Devices: Precision components for surgical instruments and devices.

– Construction: Structural components for buildings and infrastructure.

– Consumer Goods: Production of parts for household appliances and electronic devices.

– Renewable Energy: Components for solar panels and wind turbines.

– Telecommunications: Parts for communication devices and infrastructure.

– Agriculture: Durable components for farming machinery and equipment.

– Defense: High-strength parts for military applications.

SourcifyChina is a premier supplier of stamping parts essential for various industrial applications. Their material selection includes metals like steel, aluminum, brass, and copper. Each material is chosen to ensure durability and performance, meeting the specific requirements of diverse manufacturing sectors.

Steel, a primary choice, offers high strength and resistance to wear and tear. It is perfect for heavy-duty components and ensures longevity even in challenging environments. Their stainless steel variants provide added protection against corrosion.

Aluminum, valued for its lightweight and robust nature, makes it essential for applications where reducing weight without compromising strength is crucial. It is best suited for sectors like aerospace and automotive, where efficiency is critical.

Brass and copper, known for their excellent conductivity, are ideal for electrical and plumbing applications. These metals also add an aesthetic appeal due to their visually striking appearance, making them a favorite for decorative parts.

SourcifyChina’s commitment to quality and variety ensures that they can meet the needs of diverse industries. Whether it’s for high-strength requirements or applications demanding lightweight or aesthetic materials, they provide a wide range of options to choose from.

SourcifyChina stamping parts suppliers are renowned for their meticulous quality control manufacturing processes. They initiate with stringent raw material inspections, ensuring only high-grade metals enter production. Advanced machinery and precision tools are employed, followed by calibration checks to maintain accuracy and consistency in output.

Quality assurance continues through in-line inspections during manufacturing, where operators perform frequent checks on dimensions and tolerances. Automated systems aid in detecting defects early, ensuring prompt corrective measures. This minimizes waste and ensures adherence to strict quality standards.

Final inspections involve comprehensive testing of finished products, including durability and stress resistance, to guarantee compliance with client specifications. Aiding this process, advanced software validates data, ensuring transparency and reliability.

SourcifyChina also employs continuous improvement methodologies like Six Sigma and Lean Manufacturing, striving for operational excellence. Feedback loops from clients are integrated into the process, fostering innovation and quality enhancement.

In conclusion, SourcifyChina stamping parts suppliers’ rigorous quality control procedures ensure the production of high-quality, reliable components. Their commitment to excellence underpins their reputation, making them trusted partners in the manufacturing industry.

SourcifyChina specializes in delivering high-quality stamping parts for diverse industries. These suppliers boast advanced machinery and precision tooling, ensuring superior product quality and consistency. They are adept at handling complex designs, offering customized solutions to meet individual client needs.

A key strength of SourcifyChina’s stamping parts suppliers is their commitment to innovation. Utilizing the latest technologies, they continuously enhance their manufacturing processes, thus optimizing both efficiency and product quality. This dedication to innovation also facilitates rapid prototyping and reduces time-to-market.

SourcifyChina suppliers maintain rigorous quality control measures throughout the production process. Each part undergoes meticulous inspection to ensure it meets stringent international standards. This commitment to quality ensures end products are reliable, durable, and fit for purpose.

Collaboration is another hallmark of SourcifyChina’s suppliers. They work closely with clients to understand their specific requirements, enabling them to deliver tailored solutions. This client-centric approach fosters long-term partnerships and consistently high customer satisfaction.

In addition to technical capabilities, SourcifyChina’s suppliers offer competitive pricing without compromising on quality. They leverage cost-effective production techniques and strategic sourcing to provide excellent value, making them attractive partners for businesses of all sizes.

Sustainability is also a core principle for SourcifyChina. Suppliers adhere to environmentally friendly practices, minimizing waste and energy consumption. This commitment not only contributes to a sustainable future but also aligns with the evolving values of eco-conscious clients.

Overall, SourcifyChina stamping parts suppliers represent a blend of advanced technology, rigorous quality control, client-focused collaboration, competitive pricing, and sustainability. This comprehensive approach ensures they remain at the forefront of the stamping parts industry, delivering unparalleled value to their clients.

Stamping parts suppliers play a vital role in manufacturing by delivering high-quality, precisely engineered components. Their expertise ensures cost-effectiveness and operational efficiency for various industries.

– Quality Assurance: Professional stamping suppliers adhere to stringent quality standards, providing reliable and consistent parts that meet industry specifications.

– Cost-Effectiveness: Mass production capabilities reduce per-unit costs, enabling businesses to scale efficiently while maintaining quality.

– Customization: Suppliers offer tailored solutions, allowing for design flexibility to meet unique project requirements.

– Rapid Turnaround: Advanced machinery and streamlined processes ensure quick production times, meeting tight deadlines.

– Material Selection: Access to a wide range of materials, including metals and alloys, ensures the right fit for any application.

– Reduced Waste: Precision stamping minimizes material waste, promoting sustainability and cost savings.

– Scalability: Suppliers can handle small to large volume orders, accommodating business growth and fluctuating demands.

– Technological Expertise: Utilization of cutting-edge technology enhances accuracy and capabilities, ensuring innovative solutions.

– Compliance: Knowledge of industry regulations ensures all parts meet legal and safety requirements.

– Supply Chain Optimization: Reliable sourcing of materials and parts streamlines the supply chain, reducing delays and enhancing efficiency.

– Maintenance and Support: Ongoing technical support and maintenance services help maintain equipment performance and longevity.

– Industry Experience: Suppliers’ extensive experience across various sectors enables them to provide insights and best practices.

– Partnership Opportunities: Long-term relationships with suppliers foster collaboration and innovation, leading to better product development.

– Prototyping Services: Quick and efficient prototyping aids in design verification and shortens development cycles.

– Advanced Inspection Techniques: Cutting-edge inspection methods ensure defect-free parts, enhancing overall product quality.

Partnering with reputable stamping parts suppliers offers myriad advantages that drive productivity, cost savings, and innovation in manufacturing processes.

Stamping parts suppliers offer a range of services and features essential for manufacturing high-quality metal components. Their specialties ensure precision, cost-efficiency, and reliability.

– Customization: Tailored solutions to meet specific customer needs, including custom designs and specifications.

– High Precision: Advanced machinery and technology ensure accurate and consistent part dimensions.

– Material Variety: Capability to work with a broad range of metals including steel, aluminum, copper, and specialized alloys.

– Volume Flexibility: Efficient production processes that accommodate both small batches and large-scale orders with quick turnaround times.

– Quality Control: Rigorous inspection protocols and certification standards, often adhering to ISO and other industry-specific quality management systems.

– Advanced Technology: Utilization of state-of-the-art tools such as CNC machines, automated stamping presses, and CAD/CAM software for optimal design and production.

– Experienced Workforce: Skilled engineers and technicians with extensive knowledge and expertise in metal stamping processes.

– Tooling and Die Services: In-house tooling design and maintenance to ensure prolonged tool life and consistent part quality.

– Eco-Friendly Practices: Implementation of sustainable practices such as material recycling and energy-efficient machinery.

– Cost-Effective Solutions: Competitive pricing models, bulk ordering discounts, and value-added services to reduce overall production costs.

– After-Sales Support: Ongoing customer service, including troubleshooting, maintenance, and logistics assistance.

– On-Time Delivery: Strong logistics networks and supply chain management to ensure timely delivery of products.

By choosing a reputable stamping parts supplier, businesses can enhance their product quality, reduce time-to-market, and achieve greater overall efficiency in their production processes.

SourcifyChina is a renowned provider of custom stamping parts, catering to various industries with precision and excellence. They leverage cutting-edge technology to deliver high-quality products tailored to specific client needs. Their extensive network of suppliers ensures a diversified range of stamping parts, meeting various industrial standards and specifications.

Their customized products span numerous applications, from automotive parts to electronic components. Offering solutions that fit unique project requirements, they prioritize both functionality and durability. SourcifyChina’s expertise extends to intricate designs and complex manufacturing processes, making them a trusted partner for bespoke stamping needs.

Clients benefit from SourcifyChina’s streamlined procurement process, saving time and reducing costs. They maintain stringent quality control measures throughout the supply chain, ensuring every product meets the highest standards. Their commitment to client satisfaction is evident through their prompt delivery schedules and responsive customer service.

Project management is a core strength of SourcifyChina. They collaborate closely with clients from the initial design phase to final production, ensuring seamless project execution. Their knowledgeable team offers expert guidance on material selection, cost optimization, and design improvements, ensuring successful outcomes for projects of any scale.

In conclusion, SourcifyChina is a dependable choice for businesses seeking top-quality custom stamping parts. Their combination of advanced technology, rigorous quality control, and dedicated project management ensures that every product not only meets but exceeds client expectations. By choosing SourcifyChina, clients are assured of reliable, timely, and cost-effective solutions tailored to their specific needs.

SourcifyChina is a distinguished stamping parts supplier based in the heart of China’s bustling manufacturing industry. Renowned for their precision and reliability, the company specializes in delivering high-quality stamped components to a diverse range of industries, including automotive, electronics, and machinery. With a commitment to innovation and excellence, SourcifyChina employs state-of-the-art technology and rigorous quality control processes to ensure each part meets stringent international standards. Their strategic location in China allows for cost-effective production and swift logistics, ensuring timely delivery to clients worldwide. Dedicated to fostering long-term partnerships, SourcifyChina emphasizes customer satisfaction through personalized service, technical support, and continuous improvement in their manufacturing processes. Their robust supply chain and skilled workforce make them a formidable player in the global market for stamped parts, continually enhancing their reputation as a reliable and efficient supplier.

Stamping parts suppliers play a crucial role in the aerospace, defense, and marine industries, providing precision-engineered components essential for the functionality and reliability of various systems. In aerospace, the need for lightweight yet durable materials requires advanced stamping techniques to produce components like brackets, clips, and fasteners. These parts must meet stringent quality and performance standards to ensure safety and efficiency in aircraft operations. Stamping suppliers employ high-tech machinery and specialized processes to achieve the necessary tolerances and finishes, often working with materials such as titanium and aluminum alloys that are commonly used in aerospace applications.

In the defense sector, stamped parts are used extensively in the production of military vehicles, weaponry, and communication systems. The components must withstand harsh environments and high-stress conditions, necessitating the use of robust materials and precision manufacturing. For marine applications, reliable stamped parts are essential for shipbuilding, underwater vehicles, and various marine equipment. Corrosion resistance and durability are critical factors, given the challenging marine environments. Stamping parts suppliers help ensure the longevity and performance of marine systems by providing high-quality components made from stainless steel and other corrosion-resistant materials. Across these industries, the expertise of stamping parts suppliers is indispensable, delivering cost-effective, reliable solutions that meet rigorous standards and contribute to the innovation and advancement of aerospace, defense, and marine technologies.

Stamping parts suppliers play a pivotal role in the automotive industry, delivering precision-engineered components essential for vehicle manufacturing. These suppliers produce a wide range of metal parts, including body panels, brackets, and structural components that contribute to the overall safety and durability of automobiles. Utilizing advanced stamping techniques, they ensure that each part meets strict tolerances and quality standards necessary for the assembly line. Through processes like progressive stamping and deep drawing, suppliers can produce complex parts efficiently and cost-effectively, which is vital for meeting the high-volume demands of the automotive sector. Their expertise in metallurgy and tooling design also allows them to work with diverse materials such as aluminum, steel, and special alloys, providing solutions tailored to specific automotive applications.

In the electronics industry, stamping parts suppliers offer indispensable solutions for the production of various components, including connectors, shielding, and enclosures. Electronics manufacturing demands precision and reliability, characteristics well-suited to the high levels of accuracy provided by metal stamping processes. Miniaturization trends in electronics drive the need for increasingly intricate parts, which stamping suppliers achieve through processes such as fine blanking and micro-stamping. These suppliers work closely with electronics manufacturers to develop customized parts that meet stringent performance and regulatory standards, often dealing with conductive and non-conductive metals to enhance electronic performance and durability. By leveraging their advanced stamping technologies, suppliers help ensure that electronic devices are not only robust and efficient but also more cost-effective to produce, thereby supporting innovation and growth within the industry.

Stamping parts suppliers play a crucial role in the construction industry by providing essential components that ensure structural integrity and efficiency. These suppliers specialize in producing high-precision metal parts used in various construction applications, such as framing, roofing, and foundation supports. Components like brackets, joists, and connectors are meticulously stamped to meet the exact specifications required for different construction projects. The precision and durability of these stamped parts are pivotal in maintaining the safety standards of buildings and infrastructure. Furthermore, the ability to produce large quantities of uniform parts rapidly aids in expediting construction timelines and reducing project costs. Stamping parts suppliers thereby contribute significantly to the overall quality and efficiency of construction endeavors, facilitating the development of robust and reliable structures.

In the energy sector, stamping parts suppliers are indispensable for manufacturing components used in renewable energy systems, power distribution, and energy storage. High-precision metal parts are critical in the production of solar panels, wind turbines, and battery storage units. For instance, the frames and brackets in solar panels must be flawlessly crafted to ensure optimal positioning and durability in varying environmental conditions. Similarly, the intricate components in wind turbines and energy storage systems require the exacting standards that only high-quality stamped parts can provide. These suppliers also support the energy sector by producing parts essential for electrical transmission and distribution networks. Stamped parts such as electrical connectors, terminals, and switches are integral to the efficient and safe distribution of electricity. By delivering reliable and precisely-manufactured components, stamping parts suppliers enhance the performance and longevity of vital energy systems, thus playing a pivotal role in advancing sustainable energy initiatives.

The industrial equipment industry heavily relies on stamping parts suppliers to produce a wide array of components essential for manufacturing machinery, tools, and various industrial devices. Stamping, a process that involves the use of die and punches to shape metal sheets into desired forms, is foundational in creating precision parts such as brackets, housings, and enclosures. These components are vital for the structural integrity and functionality of industrial equipment, ensuring that machines operate efficiently and safely. Suppliers specializing in stamping parts can produce high volumes of parts with consistent quality, which is critical for maintaining the production schedules and reliability of equipment in industries such as automotive, aerospace, and heavy machinery.

Additionally, advancements in stamping technology, such as progressive die stamping and the integration of automated systems, have further expanded the capabilities and applications of stamping parts suppliers in the industrial equipment sector. These technological advancements enable the production of complex parts with intricate geometries and tight tolerances, reducing the need for secondary machining processes and lowering overall production costs. Customization is another key advantage; suppliers can collaborate with equipment manufacturers to design bespoke parts that meet specific requirements, enhancing the performance and lifespan of industrial machines. Overall, the partnership between industrial equipment manufacturers and stamping parts suppliers is crucial for driving innovation, efficiency, and competitiveness in the industrial sector.

Medical devices are intricate instruments critical in diagnosing, treating, and monitoring health conditions. One essential aspect of their manufacturing is the precision and reliability of their components, often supplied through stamping parts suppliers. These suppliers specialize in the high-precision stamping of metal and sometimes plastic parts required for various medical devices. This process involves converting flat metal sheets into specific shapes using dies and stamping presses. The precision stamped parts can range from tiny, intricate components used in surgical instruments to larger, robust parts found in diagnostic machinery. Given the stringent regulatory and performance standards in the medical industry, these suppliers must adhere to rigorous quality control measures to ensure the parts meet exacting specifications, retain strength under stress, and are free from contaminants that could jeopardize patient safety.

Furthermore, the partnership with stamping parts suppliers significantly enhances the efficiency and innovation in medical device manufacturing. By outsourcing to specialized suppliers, medical device companies can focus on core competencies like product design and market expansion. Stamping parts suppliers often invest in advanced technologies such as progressive die stamping, laser cutting, and computer-aided design (CAD) to produce complex parts with exceptional accuracy and consistency. This collaboration also drives cost-effectiveness by reducing material waste and streamlining production timelines, which is especially crucial in the competitive healthcare sector. Additionally, the versatility of stamped parts allows for custom solutions tailored to new and emerging medical technologies, supporting innovations that improve patient outcomes and advance healthcare practices globally.

Stamping parts suppliers play a crucial role in the machining and manufacturing industries, providing essential components needed for a wide range of applications. Stamping involves the use of a stamping press to shape or cut metal sheets into desired forms, often in large quantities. This process is favored for its speed, precision, and cost-effectiveness, particularly in industries such as automotive, aerospace, and consumer electronics. For instance, in the automotive industry, stamped parts are used to create everything from intricate engine components to large body panels, contributing to both the performance and aesthetic appeal of vehicles. The accuracy and repeatability of stamping operations ensure that each part adheres to stringent quality and tolerance standards, reducing waste and enhancing production efficiency.

Additionally, stamping parts suppliers are integral to the fabrications of complex assemblies in electronic devices, where precise and consistent component shapes are vital for functionality and performance. The versatility of stamping allows for a variety of operations such as blanking, piercing, bending, and forming, which can be tailored to produce parts with complex geometries and high-strength characteristics. Advances in stamping technology, including progressive dies and computer-aided design (CAD), have further enhanced the capabilities of suppliers to meet the evolving demands of modern manufacturing. These suppliers often offer value-added services like heat treatments, coatings, and assembly, providing comprehensive solutions that streamline production workflows. By partnering with reliable stamping parts suppliers, manufacturers can achieve superior product quality, increased production speeds, and reduced operational costs, driving innovation and competitiveness in their respective markets.

Sure, here are some FAQs with their answers:

1. What types of stamping parts does SourcifyChina Factory manufacture?

– SourcifyChina Factory specializes in a wide range of stamping parts, including brackets, clips, washers, spacers, and custom metal components made from various materials like steel, aluminum, brass, and copper.

2. How does SourcifyChina ensure the quality of its stamping parts?

– Quality assurance is a top priority at SourcifyChina. We employ rigorous quality control measures, including material certification, dimensional inspections, and functional testing. Our factory is ISO certified, ensuring adherence to international quality standards.

3. Can SourcifyChina provide custom stamping solutions?

– Yes, SourcifyChina offers custom stamping solutions tailored to unique specifications. Our experienced engineering team works closely with clients to design and produce parts that meet precise requirements.

4. What industries do SourcifyChina’s stamping parts cater to?

– Our stamping parts are used in various industries, including automotive, electronics, aerospace, and consumer goods. We are capable of meeting industry-specific requirements for high precision and durability.

5. What is the typical lead time for stamping parts orders?

– The lead time depends on the complexity and volume of the order. Generally, prototypes can be produced within 2-3 weeks, while full production runs may take 4-6 weeks. We offer expedited services for urgent needs.

6. Does SourcifyChina offer any post-manufacturing services?

– Yes, we provide several post-manufacturing services, including plating, anodizing, heat treatment, and assembly. These services help deliver finished products that are ready for immediate use.

7. How does SourcifyChina handle international shipping and logistics?

– We have an experienced logistics team that handles all aspects of international shipping. We work with reliable freight forwarders to ensure timely and safe delivery of products worldwide.

8. What are the payment terms and conditions at SourcifyChina?

– Our standard payment terms are 30% deposit upon order confirmation, with the remaining 70% due before shipment. We also offer flexible payment options and terms upon agreement.

9. How can I request a quote from SourcifyChina for my stamping parts project?

– You can request a quote by visiting our website and filling out the inquiry form, or by directly contacting our sales team via email or phone. Please provide detailed information about your project requirements to facilitate an accurate quote.

When working with stamping parts suppliers like SourcifyChina, there are several key tips to ensure a successful partnership:

1. Clear Specifications:

– Provide detailed drawings and specifications including material types, tolerances, and surface finishes.

– Use universal formats (e.g., CAD files) to avoid miscommunication.

2. Supplier Assessment:

– Verify the supplier’s capabilities through audits or virtual tours.

– Check certifications like ISO 9001 to ensure quality standards.

3. Sample Approval:

– Request initial samples (first articles) before mass production to verify the quality and adherence to specifications.

– Make necessary adjustments based on sample reviews.

4. Communication:

– Maintain open lines of communication with regular updates and status checks.

– Use project management tools to track progress and address any issues promptly.

5. Quality Control:

– Implement strict quality control measures both in-house and at the supplier’s end.

– Utilize third-party inspection services if necessary to avoid conflicts of interest.

6. Lead Time Management:

– Plan for realistic lead times considering production and shipping.

– Factor in potential delays and incorporate buffer periods to your schedule.

7. Cost Analysis:

– Negotiate pricing based on volume and long-term collaboration.

– Consider all costs including logistics, duties, and warehousing.

8. Legal Agreements:

– Draft clear contracts outlining responsibilities, payment terms, and confidentiality clauses.

– Protect intellectual property with non-disclosure agreements.

9. Sustainability:

– Evaluate the supplier’s commitment to sustainable practices.

– Opt for eco-friendly materials and processes where possible.

10. Feedback Loop:

– Establish a mechanism for ongoing feedback and continuous improvement.

– Address issues promptly and foster a collaborative relationship.

By following these tips, you can enhance efficiency, ensure quality, and build a strong, long-term partnership with stamping parts suppliers like SourcifyChina.

Q: What should I consider when selecting a stamping parts supplier from SourcifyChina Factory?

A: When selecting a supplier, consider their production capacity, quality control processes, material sourcing, lead times, cost, and past customer reviews. Ensure they meet industry standards and specific requirements for your project.

Q: How do I verify the quality of stamping parts from SourcifyChina Factory?

A: Verify quality by requesting samples, reviewing their ISO certification, and evaluating their quality control processes. Ask for references and consider conducting a factory audit or third-party inspection.

Q: What materials can SourcifyChina Factory work with for stamping parts?

A: SourcifyChina Factory typically handles a variety of materials, including steel, aluminum, brass, copper, and various alloys. Confirm with the supplier to ensure they can work with the specific material you require.

Q: Can SourcifyChina Factory handle custom stamping part designs?

A: Yes, SourcifyChina Factory can handle custom designs. Provide detailed drawings, specifications, and requirements. Communicate directly with their engineering team to ensure they understand your needs.

Q: What are the lead times for stamping parts from SourcifyChina Factory?

A: Lead times vary depending on the complexity and volume of the order. Generally, prototypes may take a few weeks, while large production runs might take a few months. Confirm specific lead times with the supplier.

Q: How does SourcifyChina Factory ensure consistency in their stamping parts production?

A: They ensure consistency through rigorous quality control, regular equipment maintenance, skilled workforce, and continuous monitoring during production. They may also use statistical process control (SPC) methods.

Q: What are the payment terms when dealing with SourcifyChina Factory?

A: Payment terms can vary but often include options like 30% deposit with the balance paid before shipment, net 30, or letters of credit. Negotiate terms that work best for your financial situation.

Q: How do I handle logistics and shipping for parts ordered from SourcifyChina Factory?

A: Collaborate with the supplier or a logistics provider to manage shipping. SourcifyChina Factory may offer shipping services or recommend reliable partners. Consider ocean freight for cost savings or air freight for faster delivery.

Q: Are there minimum order quantities (MOQs) for stamping parts at SourcifyChina Factory?

Sourcing stamping parts suppliers from SourcifyChina or any other platform requires methodical steps to ensure quality, cost-efficiency, and reliability. Here’s a concise guide to help you:

1. Define Your Requirements: Clearly outline the specifications of your stamping parts, including materials, dimensions, tolerances, and quantities. This precision helps in finding a supplier that can meet your exact needs.

2. Platform Search: Utilize SourcifyChina’s search filters to narrow down suppliers. Keywords such as “stamping parts,” “metal stamping,” and specific materials (e.g., “steel stamping parts”) will streamline the process.

3. Evaluate Supplier Profiles: Assess the credibility of suppliers by reviewing their profiles, which include business scope, years of experience, certifications (e.g., ISO9001), and client reviews. Shortlist those with a strong track record in stamping parts.

4. Request Quotations and Samples: For accurate pricing and quality confirmation, request detailed quotations and samples from at least three shortlisted suppliers. Evaluate samples based on your specifications and quality standards.

5. Verify Manufacturing Capabilities: Ensure the supplier has the necessary machinery and technical expertise. Request a factory tour or a virtual walkthrough to observe their production process and equipment.

6. Negotiate Terms: Discuss pricing, payment terms, lead times, and logistics. Ensure clarity on all aspects to avoid future disputes. Negotiate favorable terms while maintaining a focus on quality and delivery reliability.

7. Check References and Conduct Audits: Reach out to previous clients for feedback and perform background checks. Conducting a third-party audit can also provide an unbiased assessment of the supplier’s operations.

8. Establish Clear Communication: Set up regular communication channels with your supplier to monitor production progress and address any issues promptly.

By following these steps, you can efficiently source reliable stamping parts suppliers from SourcifyChina, ensuring your production needs are met with quality and on time.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.