Choosing SourcifyChina Factory for purchasing steel castings from China guarantees unmatched expertise. Their team of professionals leverages years of industry experience to ensure high-quality products. By opting for SourcifyChina, buyers access top-notch steel castings that meet international standards, ensuring durability and reliability in various applications.

One of the standout features of SourcifyChina is their stringent quality control measures. Each steel casting undergoes rigorous testing to meet stringent specifications. This commitment to quality ensures buyers receive only the best products, minimizing defects and enhancing performance.

Additionally, SourcifyChina’s competitive pricing makes them an ideal choice. They provide cost-effective solutions without compromising on quality, making it easier for buyers to maintain their budget while procuring high-quality steel castings. This affordability is accompanied by excellent customer service, addressing buyer concerns promptly.

Moreover, SourcifyChina boasts a swift and efficient logistics network. This ensures timely delivery of steel castings, reducing lead times and enabling buyers to maintain smooth production schedules. With simplified shipping processes, buyers can rest assured that their orders will arrive on time.

Finally, the company’s commitment to sustainable practices ensures that all manufacturing processes adhere to environmental norms. By choosing SourcifyChina, buyers not only obtain superior steel castings but also contribute to eco-friendly manufacturing. With a blend of quality, affordability, and sustainability, SourcifyChina Factory remains the go-to choice for steel casting purchases in China.

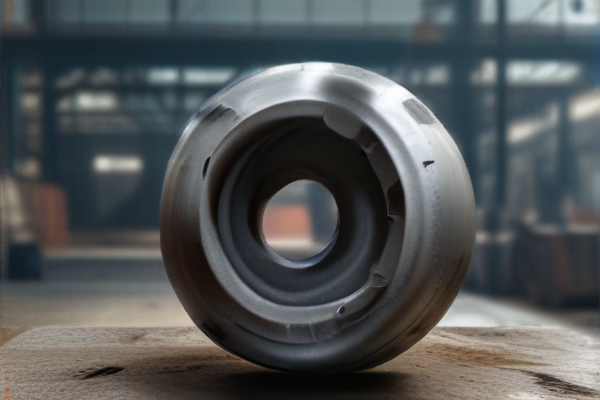

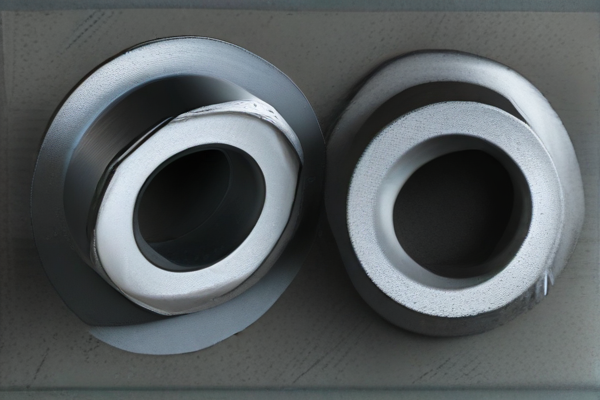

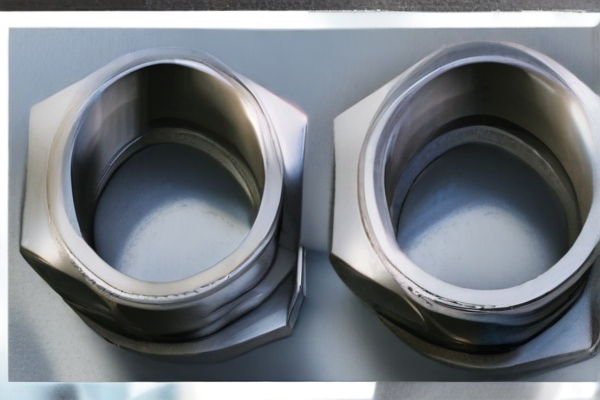

Steel casting is a process where molten steel is poured into a mold to create a specific shape. There are various types and options available in steel casting for diverse applications.

– Sand Casting: Utilizes sand molds and is ideal for large components. Cost-effective but has a rough surface finish.

– Investment Casting (Lost Wax Casting): Produces high-precision components with excellent surface finishes, ideal for complex shapes.

– Die Casting: Involves forcing molten steel into metal molds under high pressure; best for high quantities and precise dimensions.

– Centrifugal Casting: Uses a spinning mold to shape cast parts, primarily for cylindrical components like pipes and bearings.

– Continuous Casting: Used for producing long steel products like billets, slabs, and beams with consistent quality.

– Shell Mold Casting: Similar to sand casting but uses a resin-covered sand mold, which offers better precision and surface finish.

– Plaster Mold Casting: Uses plaster molds for complex shapes with a finer finish than sand casting, but limited to non-ferrous materials.

– Vacuum Casting: Applied for parts needing clean and precise castings as it reduces porosity and impurities.

– Permanent Mold Casting: Employs reusable metal molds, ideal for mass production of small and medium-sized parts with good dimensional accuracy.

Each method has unique benefits and limitations, making the choice dependent on factors like desired precision, cost, production volume, and material properties.

Steel casting is a vital manufacturing process used to create complex shapes, providing strength and durability for various applications. It plays a critical role in both industrial and commercial sectors.

– Automotive Industry: Components such as engine blocks, crankshafts, and suspension parts.

– Construction: Load-bearing structures, beams, and columns.

– Heavy Machinery: Parts of excavators, loaders, and mining equipment.

– Aerospace: Landing gear components and structural parts.

– Oil and Gas: Valves, pumps, and drilling equipment.

– Railway: Wheels, couplers, and brake components.

– Military: Armored vehicles, weaponry, and support structures.

– Marine: Ship anchors, propellers, and hull components.

– Agriculture: Tractor parts, plowshares, and harvesting equipment.

– Electrical: Transformer and motor housings.

– Industrial Equipment: Gearboxes, conveyor system components, and industrial fans.

– Medical: Surgical instruments and equipment housings.

Steel casting ensures high performance and reliability across these diverse fields.

SourcifyChina specializes in delivering high-quality steel casting materials suitable for a plethora of industrial applications. The steel castings offered by SourcifyChina are renowned for their durability, strength, and resistance to wear and corrosion, making them ideal for heavy-duty machinery and structural components.

The steel castings from SourcifyChina undergo rigorous testing to ensure they meet stringent quality standards. This meticulous attention to detail guarantees a longer lifespan and superior performance under extreme conditions. Industries such as automotive, construction, and marine heavily rely on these robust steel components for reliable and safe operations.

SourcifyChina provides a variety of steel grades to meet specific customer requirements. Each grade is engineered for distinct functionalities, ranging from enhanced weldability to superior tensile strength. This customization enables clients to choose the most suitable material for their specific application, ensuring efficiency and efficacy.

In collaboration with advanced manufacturing techniques, SourcifyChina employs state-of-the-art molding and casting processes. These methods not only improve the overall quality of the steel castings but also reduce production time and costs. As a result, customers benefit from high-end products delivered within shorter lead times.

Finally, SourcifyChina is committed to sustainable practices and eco-friendly manufacturing. Their advanced facilities are equipped with efficient, low-emission machinery, and they emphasize the recycling of scrap materials. This dedication to environmental stewardship mirrors their commitment to providing exceptional steel casting products while minimizing their ecological footprint.

SourcifyChina ensures top-notch steel casting quality through rigorous control processes. They meticulously select raw materials, opting only for premium-grade steel. This initial step guarantees a strong foundation for casting production.

Advanced machinery and technology are employed to enhance precision in the manufacturing process. Modern equipment ensures that each cast meets stringent dimensional and structural requirements, minimizing defects and inconsistencies.

Skilled technicians conduct frequent inspections and tests, including non-destructive testing (NDT). This method detects any internal flaws without damaging the steel, ensuring the end product’s integrity and durability.

SourcifyChina places a strong emphasis on continual training and development of their workforce. By keeping their staff updated with the latest industry advancements and best practices, they maintain high standards in their manufacturing processes.

The final products undergo thorough quality assurance checks before dispatch. These checks ascertain that the steel casts meet client specifications and international quality standards. This multi-layered approach ensures superior final products and customer satisfaction.

SourcifyChina excels in producing high-quality steel castings for diverse industries. Their advanced manufacturing facilities ensure precision and durability, catering to custom requirements with innovative solutions. Leveraging cutting-edge technology, they maintain stringent quality control, ensuring each product meets international standards.

Their capabilities span a vast range of applications, including automotive, machinery, and construction. SourcifyChina’s expertise allows them to craft complex components with remarkable accuracy, enhancing their clients’ operational efficiency. With a robust supply chain, they provide timely delivery and competitive pricing, making them a preferred partner globally.

SourcifyChina employs a dedicated team of engineers and technicians who work meticulously to optimize casting processes. Through continuous improvement and rigorous testing, they achieve exceptional product consistency. Their commitment to sustainability also drives them to adopt eco-friendly practices, reducing waste and energy consumption.

In addition to standard steel castings, SourcifyChina offers bespoke services, tailoring products to specific customer requirements. This versatility enables them to address unique challenges and deliver custom-engineered solutions. Their proactive approach in understanding client needs ensures a collaborative and successful partnership.

Overall, SourcifyChina’s steel casting capabilities reflect a blend of technical expertise, innovative practices, and customer-centric solutions. By prioritizing quality, efficiency, and sustainability, they not only meet but exceed industry expectations, positioning themselves as a leader in the global steel casting market.

Steel casting offers numerous benefits, making it essential in various industries due to its versatility, strength, and durability. It provides precision in complex designs and superior resistance to wear and corrosion.

– Strength and Durability: Steel castings are incredibly strong and durable, capable of withstanding heavy loads and harsh conditions, which makes them ideal for construction, mining, and industrial applications.

– Design Flexibility: The casting process allows for intricate and complex designs, enabling the production of components that other methods cannot achieve, which is crucial for specialized machinery and equipment.

– Corrosion Resistance: Steel castings can be alloyed with elements such as chromium and nickel to enhance their corrosion resistance, making them suitable for use in aggressive environments like marine or chemical industries.

– Cost-Efficiency: Steel casting helps reduce material waste and labor costs. The ability to cast large structures as a single piece minimizes the need for assembly, thereby saving time and reducing potential weak points.

– Machinability and Weldability: Cast steel is easily machinable and weldable, allowing for further customization and repair of components, which enhances the lifespan and usability of machinery parts.

– Recyclability: Steel is one of the most recyclable materials, contributing to environmental sustainability by reducing waste and conserving resources.

– Enhanced Performance: The high strength-to-weight ratio and excellent thermal and electrical conductivity of steel castings improve the efficiency and performance of various applications, from automotive to aerospace industries.

– Versatility: Used in a wide range of sectors, steel castings are adaptable to numerous applications, from everyday tools to highly specialized industrial machinery.

In summary, steel casting is a versatile manufacturing process that offers unmatched strength, design flexibility, and cost-efficiency, making it a cornerstone in many industrial applications.

Steel casting is a manufacturing process where molten steel is poured into a mold to create a desired shape. It offers numerous features suitable for diverse applications.

– Durability: Steel casting provides high strength and longevity, making it ideal for heavy-duty applications.

– Precision: Complex geometries and intricate designs can be achieved with high accuracy.

– Versatility: Suitable for various industries including automotive, construction, and aerospace.

– Corrosion Resistance: Enhanced properties can be achieved through alloying to resist rust and wear.

– Heat Resistance: Excellent performance in high-temperature environments.

– Customizability: Materials and properties can be tailored to specific needs.

– Cost-Effective: Reduced material waste and efficient production processes.

– Recyclability: Steel is highly recyclable, reducing environmental impact.

SourcifyChina is a prominent provider of custom steel casting products, delivering high-quality solutions tailored to a variety of industries. With an emphasis on precision and durability, they cater to the specific needs of their clients, ensuring optimal performance and satisfaction.

Their steel casting offerings include a wide range of products such as valves, pumps, components for heavy machinery, and other industrial applications. These products are made using advanced casting techniques, resulting in superior strength and reliability, which are crucial for demanding environments.

SourcifyChina places a strong emphasis on innovation, utilizing state-of-the-art technology and equipment to meet the evolving requirements of modern projects. Their expert team works closely with clients, from initial design to final production, ensuring that every detail is crafted to perfection.

Clients can rely on SourcifyChina for comprehensive support throughout the project lifecycle. The company’s commitment to quality and customer satisfaction makes them a trusted partner for businesses seeking efficient and cost-effective steel casting solutions. The collaborative approach encourages open communication, leading to the successful completion of projects on time and within budget.

By focusing on customization and excellence, SourcifyChina has earned a reputation as a leader in the steel casting industry. Their expertise and dedication ensure that every project meets the highest standards of quality and performance, positioning them as the go-to source for steel casting needs.

SourcifyChina Steel Casting Company stands as a distinguished leader in the steel casting industry, renowned for its commitment to quality, precision, and customer satisfaction. Based in China, the company specializes in the manufacture of high-grade steel castings, serving a wide array of industries including automotive, construction, machinery, and shipbuilding. Through the integration of advanced technology and rigorous quality control processes, SourcifyChina ensures that every product meets international standards and exceeds customer expectations. Their state-of-the-art facilities are equipped with the latest in casting technology, enabling large-scale production while maintaining exceptional accuracy and efficiency. Furthermore, SourcifyChina prides itself on its robust research and development capabilities, constantly innovating to provide tailored solutions that address the evolving needs of their global clientele. With a commitment to sustainable practices, they also focus on reducing environmental impact through advanced recycling methods and energy-efficient operations. By strategically combining tradition and innovation, SourcifyChina Steel Casting Company remains a pivotal player in the global steel market, delivering unmatched value and reliability.

Steel casting plays an indispensable role in the aerospace, defense, and marine industries, offering numerous advantages such as strength, durability, and versatility. In the aerospace sector, steel castings are used to manufacture complex and high-stress components like landing gear, engine parts, and structural elements. These castings are required to withstand extreme conditions, including high temperatures, pressure, and mechanical stress, while maintaining optimal performance and safety standards. Steel’s high tensile strength and resistance to fatigue and corrosion make it an ideal material for applications that demand reliability and longevity. Advanced casting techniques allow for the creation of near-net-shape parts, minimizing the need for extensive machining and thereby reducing production costs and lead times.

In the defense industry, steel castings are crucial for producing robust and resilient military hardware, from vehicle armor and artillery components to ship fittings and missile casings. The ability to customize alloy compositions to enhance specific properties, such as toughness or hardness, enables the production of parts that can effectively meet the rigorous demands of military operations. For the marine sector, steel castings are utilized in the construction of critical shipbuilding components like propellers, rudders, anchor systems, and engine parts. In the harsh marine environment, where exposure to saltwater and varying temperatures is constant, the corrosion resistance and durability of steel castings ensure the longevity and reliability of marine vessels. As technological advancements continue, steel casting remains a foundational technology that supports innovation and performance across these critical industries.

Steel casting plays a pivotal role in the automotive industry, where the need for robust and reliable components is paramount. One of the primary applications of steel casting in this sector is in the production of engine blocks and cylinder heads, which require materials that can withstand high temperatures and pressures. Steel castings are also employed in the manufacturing of various drivetrain components, such as transmission cases and differential housings, where their exceptional strength and durability contribute to the overall performance and longevity of the vehicle. Additionally, suspension components, including control arms and knuckles, benefit from steel casting’s ability to produce complex shapes with high precision and consistency, ensuring safe and dependable handling characteristics.

In the realm of electronics, steel casting finds its niche in the fabrication of various structural and protective components that must endure harsh conditions. For instance, steel castings are utilized in the production of heat sinks, enclosures, and mounting brackets for electronic devices. These components must often function in environments subject to extreme temperatures, vibrations, and corrosion, making steel’s inherent properties of thermal conductivity and resistance to mechanical stress highly advantageous. Furthermore, the precision achievable through steel casting allows for the production of intricate and finely detailed parts, essential for maintaining proper alignment and performance of electronic assemblies. This ensures that devices, ranging from consumer electronics to industrial control systems, operate reliably and efficiently over their intended lifespan.

Steel casting plays a crucial role in the construction industry due to its remarkable mechanical properties, including high tensile strength, durability, and versatility. Structural components such as beams, columns, and girders are often crafted from steel castings to ensure the stability and longevity of buildings, bridges, and other infrastructure. The precision inherent in the casting process allows for complex geometries and designs, which are essential for modern architectural innovations. Moreover, steel castings can be engineered to withstand harsh environmental conditions, making them ideal for both urban construction and remote or offshore installations. Their recyclability also accentuates their appeal in sustainable construction practices, enabling the development of eco-friendly structures that meet rigorous safety standards.

In the realm of energy applications, steel castings are indispensable in the manufacturing of critical components for power generation and distribution systems. Turbine housings, valve bodies, and pump casings are just a few examples where steel castings are utilized due to their ability to endure extreme temperatures and pressures. In renewable energy sectors, such as wind and hydro power, steel castings are essential for producing robust and precise parts that can handle dynamic and cyclic loads. Additionally, the oil and gas industry relies heavily on steel castings for drilling equipment, pipelines, and sub-sea components. The reliability and strength of steel castings make them ideal for these high-stakes applications, where failure is not an option and performance is paramount. As energy demands evolve and expand, steel casting technology continues to advance, offering innovative solutions to improve efficiency and operational lifespan across diverse energy sectors.

Steel casting is a fundamental process in the industrial equipment industry, offering unparalleled strength, versatility, and durability for a multitude of applications. The process involves melting steel and pouring it into molds to create components and structures that are integral to industrial machinery and equipment. This method is particularly advantageous when manufacturing parts that require complex geometries and robust mechanical properties. Heavy machinery such as cranes, loaders, and excavators rely extensively on steel castings for their frames, arms, and numerous other parts that must withstand extreme stress and harsh operational conditions. Additionally, steel castings are vital in the production of large-scale industrial equipment used in the mining, energy, and transportation sectors, where reliability and longevity are paramount.

In the realm of precision engineering, steel casting also plays a crucial role in the fabrication of intricate components that demand high tolerance levels and exceptional tensile strength. Industries such as automotive, aerospace, and defense benefit enormously from steel casted parts, which often include gears, engine blocks, and various drivetrain components. The ability to produce customized shapes and sizes with precise specifications allows manufacturers to tailor their products to specific operational needs, enhancing overall efficiency and performance. Moreover, advancements in casting technologies, such as investment casting and sand casting, have further broadened the applications and improved the quality of steel casted parts. With steel’s inherent properties of corrosion resistance, fatigue strength, and adaptability to heat treatments, steel casting remains indispensable in advancing the capabilities and reliability of industrial equipment.

Steel casting plays a crucial role in the medical device industry, primarily due to its strength, durability, and biocompatibility. The precision and reliability afforded by steel casting techniques help produce essential medical tools and components, ranging from surgical instruments to diagnostic equipment. Surgical instruments such as scalpels, forceps, and clamps require the use of high-quality materials that can withstand repeated sterilization processes without degrading. The casting process ensures that these tools meet stringent health and safety standards, providing sharpness, corrosion resistance, and long-term durability. Additionally, steel castings are used in the production of complex joint replacements and orthopedic implants, which require precisely engineered shapes to mimic the biomechanical properties of human bones and joints. The reliable performance of these steel-cast parts is paramount in ensuring successful medical outcomes for patients.

Beyond surgical tools and implants, steel casting is also employed in manufacturing vital components for various medical devices and machinery. Devices such as MRI machines, CT scanners, and ventilators contain numerous steel-cast parts that are critical to their operation. The mechanical properties of steel, such as tensile strength and hardness, make it an ideal candidate for components that endure significant mechanical stresses. Moreover, the adaptability of steel casting allows for the creation of customized parts tailored to specific medical applications, thus improving the functionality and efficiency of these devices. In sum, the integration of steel casting into the medical device sector not only enhances the quality and safety of medical tools and machines but also underpins the advancement of medical technology, ultimately contributing to improved patient care and health outcomes.

Steel casting plays a critical role in machining and manufacturing applications due to its exceptional properties, such as high strength, durability, and the ability to withstand harsh conditions. The steel casting process involves pouring molten steel into molds to produce complex shapes that would be challenging and expensive to create using other methods. This capability is particularly advantageous for producing heavy-duty components like engine blocks, gearboxes, and various other industrial parts that require high tensile strength and resistance to wear and deformation. Steel casting allows for precise control over the microstructure of the material, ensuring that the final product meets specific performance criteria and maintains dimensional accuracy.

In manufacturing, steel castings are indispensable for a wide range of industries including automotive, aerospace, construction, and heavy machinery. They enable the creation of parts that can endure extreme environmental conditions, corrosive substances, and significant mechanical stress. Additionally, steel castings can be engineered to have varying levels of hardness and toughness, making them versatile for different applications. Through processes like heat treatment and surface finishing, the performance characteristics of steel castings can be further enhanced to meet the highly specialized demands of modern manufacturing. Therefore, steel casting not only contributes to the fabrication of durable and reliable components but also optimizes production efficiency by reducing the need for extensive machining and material waste.

Sure! Here are some frequently asked questions (FAQ) with answers about manufacturing steel casting quality work from SourcifyChina factory:

1. What types of steel casting services does SourcifyChina offer?

SourcifyChina offers a wide range of steel casting services, including sand casting, investment casting (lost wax process), and die casting to meet various industrial requirements.

2. How does SourcifyChina ensure the quality of steel castings?

SourcifyChina employs advanced technology and rigorous quality control processes, including material testing, dimensional inspections, and non-destructive testing (NDT) such as X-ray and ultrasonic testing, to ensure high-quality castings.

3. What industries can benefit from SourcifyChina’s steel casting services?

SourcifyChina serves numerous industries including automotive, aerospace, construction, mining, oil & gas, and machinery manufacturing, providing them with customized, high-strength steel castings.

4. Can SourcifyChina handle custom steel casting orders?

Yes, SourcifyChina can produce custom steel castings based on specific client requirements. They work closely with clients on design, material selection, and production to deliver tailored solutions.

5. What materials are used in SourcifyChina’s steel castings?

SourcifyChina uses a variety of steel grades such as carbon steel, alloy steel, stainless steel, and high manganese steel to meet the diverse needs of their clients.

6. What is the typical lead time for a steel casting order?

The lead time depends on the complexity and volume of the order, but SourcifyChina strives to provide quick turnarounds. Generally, prototype samples take a few weeks, while large-scale productions may take several months.

7. Does SourcifyChina provide any additional services apart from steel casting?

Yes, SourcifyChina offers additional services such as heat treatment, surface finishing, machining, and assembly to provide clients with complete, ready-to-use products.

8. How can I get a quote for my steel casting project from SourcifyChina?

To get a quote, you can contact SourcifyChina directly through their website, providing detailed information about your project including design, material specifications, and quantity requirements.

9. What certifications does SourcifyChina hold to ensure compliance and quality standards?

SourcifyChina holds various certifications such as ISO 9001 for quality management systems, ensuring their manufacturing processes meet international quality standards.

Steel casting manufacturing is a complex and precise process that requires experienced professionals and advanced equipment. SourcifyChina factory is one of the well-known suppliers in this area. Here are some tips to optimize your experience with them:

1. Understand Specifications: Clearly communicate your product specifications, including dimensions, material grade, and required tolerances. This ensures that the factory can meet your exact needs.

2. Material Selection: Work closely with the engineers to select the most suitable steel alloy for your casting. Different alloys offer varied properties like corrosion resistance, strength, and ductility.

3. Prototype Development: Before proceeding to mass production, request for prototype development. This helps in identifying potential issues and making necessary adjustments early on.

4. Quality Assurance: SourcifyChina employs stringent quality control measures. Ensure that your order undergoes these checks, including non-destructive testing (NDT) methods like radiography, ultrasonic testing, and more.

5. Lead Time: Discuss the lead time upfront, considering factors such as mold preparation, casting, finishing, and inspection. This helps in planning your production schedule effectively.

6. Surface Finishing Options: Determine the type of surface finishing required for your castings. Options like machining, polishing, and coating can enhance the final product’s performance and appearance.

7. Volume Flexibility: Assess their capability to handle different order volumes. SourcifyChina can cater to both small batches and large-scale production runs, depending on your needs.

8. Cost Estimation: Obtain a detailed cost breakdown to avoid any hidden charges. Ensure that all aspects, from raw materials to shipping, are covered in the quotation.

9. Visit the Factory: If possible, visit the factory to get a firsthand look at their operations and capabilities. This also helps in building a stronger business relationship.

10. Sustainability Practices: Inquire about their sustainability practices and waste management procedures, which can impact your company’s environmental footprint.

By following these tips, you can maximize efficiency and quality in your steel casting manufacturing process with SourcifyChina.

Q: What types of steel casting services does SourcifyChina factory offer?

A: SourcifyChina factory provides a variety of steel casting services, including sand casting, investment casting, and die casting. They cater to different industrial requirements and custom specifications.

Q: How do I request a quote for my steel casting project?

A: To request a quote, you can visit the SourcifyChina website and fill out the inquiry form with your project details. You can also send an email with your drawings, specifications, and volume requirements.

Q: What is the typical lead time for steel casting orders?

A: The lead time varies depending on the complexity and volume of the order. Generally, it ranges from 4 to 8 weeks. Specific timelines will be provided once the project details are reviewed.

Q: Can SourcifyChina handle small and large volume orders?

A: Yes, SourcifyChina accommodates both small and large volume orders. They have the capacity to handle custom projects regardless of the order size.

Q: What quality assurance measures are in place?

A: SourcifyChina factory follows stringent quality assurance protocols including ISO 9001 certification, in-process inspections, and final product testing to ensure high-quality steel castings.

Q: Are there options for custom designs and specifications?

A: Absolutely. SourcifyChina specializes in custom steel castings tailored to your specific design and performance requirements. You can provide CAD files or sketches for evaluation.

Q: How does SourcifyChina ensure accurate and precise castings?

A: They utilize advanced casting technologies and CNC machining to achieve high precision. Additionally, thorough quality control checks are performed at each stage of production.

Q: What types of industries does SourcifyChina serve?

A: SourcifyChina caters to a broad range of industries including automotive, aerospace, construction, machinery, and energy sectors.

Q: Are there minimum order requirements?

A: Minimum order requirements depend on the type of casting and the complexity of the project. It is best to discuss your specific needs directly with the SourcifyChina team.

Q: How can I communicate with the SourcifyChina team during the project?

When sourcing steel castings from SourcifyChina factory, it’s essential to follow a streamlined approach to ensure high-quality products and a smooth procurement process. Here are some tips to help you:

1. Detailed Specifications: Clearly outline the specifications for your steel castings, including dimensions, material grade, weight tolerances, and any finishing requirements. Providing detailed drawings and designs can eliminate ambiguities.

2. Quality Standards: Ensure the factory adheres to relevant quality standards like ISO 9001 or ASTM. Request documentation and certifications to verify compliance.

3. Sample Request: Ask for samples before placing a large order. This allows you to inspect the quality and make any necessary adjustments early in the process.

4. Communication: Establish clear and consistent communication channels. Assign a dedicated point of contact to ensure timely updates and address any concerns promptly.

5. Factory Visit: If possible, visit the factory to evaluate their facilities, equipment, and manufacturing processes. This can provide insights into their production capabilities and quality control measures.

6. Third-Party Inspection: Consider hiring a third-party inspection service to audit the factory and inspect the products before shipment. This adds an extra layer of quality assurance.

7. Lead Time and Logistics: Discuss lead times early on and set realistic expectations. Plan the logistics, including shipping and customs clearance, to avoid delays.

8. Contracts: Use comprehensive contracts that detail all aspects of the agreement, including payment terms, delivery schedules, and quality expectations. Legal counsel can help draft and review these contracts.

9. References and Reviews: Look for reviews and references from other companies that have sourced from SourcifyChina factory. This can provide additional insights into their reliability and performance.

10. Cost Management: Compare quotes from multiple suppliers to ensure competitive pricing. Factor in all costs, including shipping, duties, and potential tariffs, to get an accurate estimate of the total expenditure.

Following these tips can help you efficiently source quality steel castings from SourcifyChina factory, ensuring a successful procurement process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.