SourcifyChina Factory offers unparalleled quality in steel grinding products, adhering to international standards. This ensures buyers receive dependable and durable materials for their manufacturing needs, ultimately saving cost and effort.

Competitive pricing at SourcifyChina provides exceptional value. Coupled with their efficient production processes, buyers can expect timely delivery and reduced overheads, benefiting their bottom line.

Customer support at SourcifyChina is outstanding, with a dedicated team ensuring seamless communication and addressing buyer concerns promptly. This fosters a reliable partnership, enhancing buyer confidence and satisfaction.

With a strong focus on innovation, SourcifyChina continuously updates its manufacturing techniques. This commitment to staying ahead ensures buyers receive the most advanced and efficient products available in the market.

In conclusion, SourcifyChina Factory stands out as a premier choice for steel grinding purchases, offering a blend of superior quality, competitive pricing, excellent customer service, and cutting-edge innovation. Buyers can rely on them for their crucial supply chain needs.

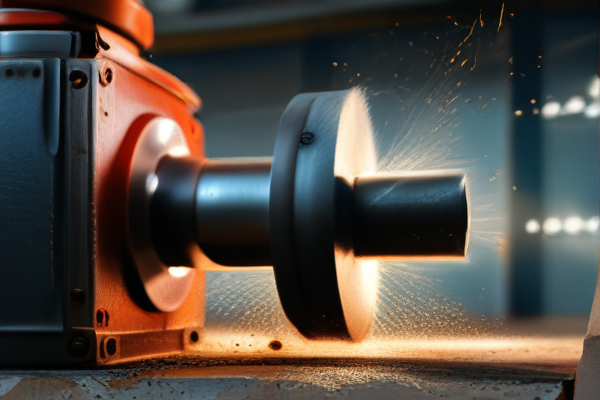

Steel grinding involves various methods to shape or finish steel, ensuring the desired surface quality and dimensional accuracy. Different types of steel grinding techniques cater to diverse industrial requirements and material properties.

– Surface Grinding: Uses a rotating abrasive wheel to produce a smooth finish on flat surfaces.

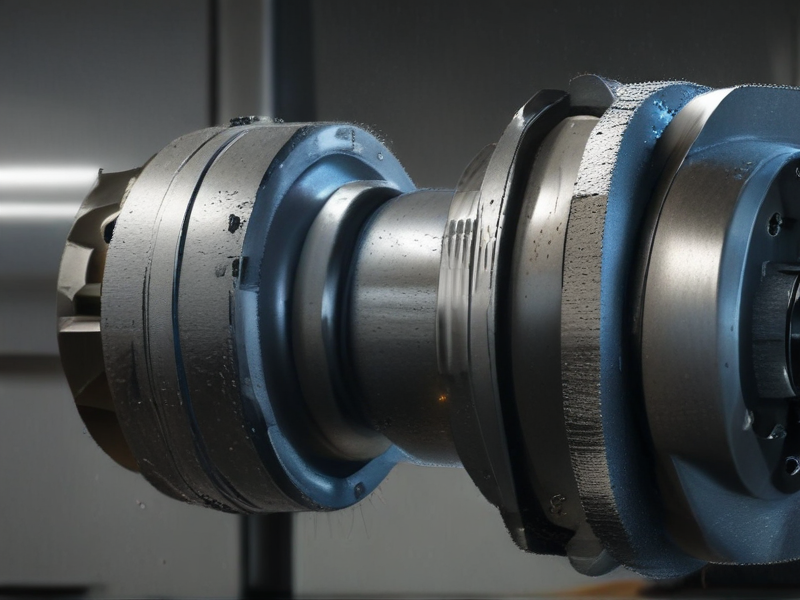

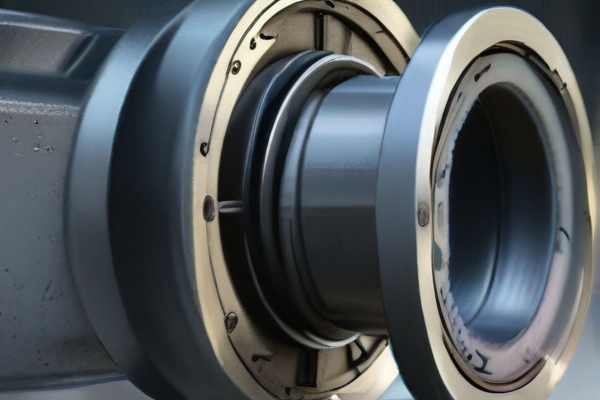

– Cylindrical Grinding: Grinds the outer surface of cylindrical objects, achieving high precision.

– Centerless Grinding: Removes material from a workpiece between two wheels, ensuring consistent and precise dimensions without the need for centering.

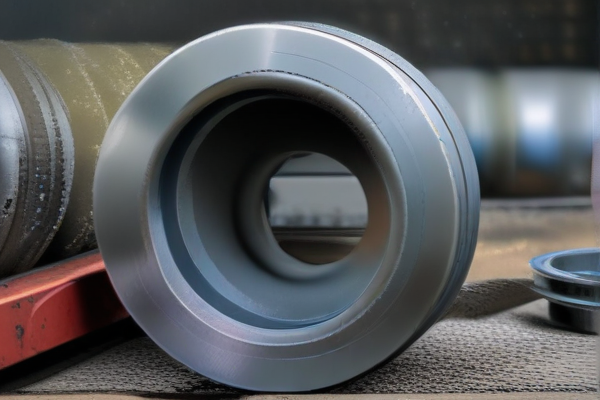

– Internal Grinding: Focuses on the internal diameter of a part, providing precision for complex inner geometries.

– Creep-Feed Grinding: A slower, more precise grinding process that removes large amounts of material in one pass.

– Blanchard Grinding: Employs a rotary table and vertical spindle for rapid material removal and flat surface creation.

– Tool and Cutter Grinding: Sharpens and refurbishes cutting tools, enhancing their lifespan and performance.

– Jig Grinding: Specializes in grinding holes and complex forms to high precision.

– Profile Grinding: Customizes the grinding wheel to match a specific profile or shape for detailed work.

– Electrochemical Grinding: Combines electrochemical machining with grinding, ideal for hard materials and creating burr-free edges.

Each of these grinding methods offers distinct advantages and is chosen based on the specific requirements of the steel workpiece, including its size, shape, and desired surface finish.

Steel grinding is crucial in various industries for processing raw materials, finishing surfaces, and manufacturing components. This process ensures precision, durability, and performance of steel parts in multiple applications.

– Automotive Industry: Precision grinding for engine components, gears, and transmission parts.

– Aerospace: High-tolerance grinding for turbine blades and structural components.

– Construction: Surface preparation of steel beams and reinforcement bars.

– Tool Manufacturing: Creating sharp and durable cutting tools, drills, and dies.

– Medical Devices: Precision grinding of surgical instruments and implants.

– Renewable Energy: Finishing of wind turbine components and hydroelectric machinery.

– Shipbuilding: Grinding for hull construction, propellers, and naval components.

– Machinery: Manufacturing and refurbishing vital machine parts like bearings and pistons.

– Mining: Processing steel components used in mining machinery and tools.

– Defense: Fabricating and finishing military equipment and armaments.

– Electronics: Producing precise and durable steel parts for electronic devices.

– Oil and Gas: Enhancing durability of drilling equipment and pipeline components.

– Railway: Manufacturing and maintaining train tracks, wheels, and other critical parts.

– Agriculture: Creating robust steel parts for farming equipment.

– Furniture: Finishing of steel frames and support structures for furniture.

– Heavy Equipment: Precision grinding for construction and industrial machinery components.

– Appliance Manufacturing: Producing high-quality parts for household appliances.

– Sports Equipment: Creating durable and precise sports gear like golf clubs and bicycles.

– Food Processing: Grinding components for food manufacturing and packaging machinery.

– Architectural: Detailing steel elements in modern architectural structures.

SourcifyChina’s steel grinding production prioritizes quality control throughout the manufacturing process. Raw materials undergo rigorous inspection for chemical composition and structural integrity to ensure the foundation is robust.

Next, advanced machinery shapes and polishes the steel. The equipment undergoes regular maintenance and calibration to maintain precision and uniformity in the steel grinding process.

Quality control personnel conduct frequent inspections and employ sophisticated testing methods, such as ultrasonic testing and UV inspections, to identify any micro-cracks, discrepancies, or defects at various stages of production.

Environmental and safety standards are strictly adhered to. SourcifyChina employs eco-friendly practices to minimize waste and emissions, and ensures worker safety through regular training and equipment upgrades.

The final products are subjected to repetitive endurance tests to simulate actual operating conditions, verifying their durability before reaching the market. Accuracy and integrity from start to finish ensure a high-quality, reliable steel grinding output.

SourcifyChina offers advanced steel grinding capabilities, ensuring precise and high-quality finishes on various steel products. Their state-of-the-art equipment and technology allow for exceptional control over the grinding process.

With a team of experienced professionals, SourcifyChina can handle diverse grinding needs, from simple surface finishes to intricate shapes and sizes. They cater to industries such as automotive, construction, and manufacturing, meeting strict specifications.

Their grinding services include cylindrical, surface, and centerless grinding, providing versatile solutions for different steel applications. They prioritize efficiency and consistency, ensuring each project meets client expectations.

SourcifyChina emphasizes quality control throughout the grinding process, utilizing rigorous testing and inspection methods. This commitment to quality guarantees durable and reliable steel products.

In addition to their technical expertise, SourcifyChina offers competitive pricing and timely delivery. Their customer-focused approach ensures that every project is completed to the highest standards and within the agreed timeframe.

Steel grinding offers numerous benefits, enhancing both industrial processes and product quality. Its primary advantages include increased precision and improved surface finish.

– Precision: Steel grinding allows for exact dimensions and tight tolerances, essential for high-precision components.

– Surface Finish: Achieves a smoother and more refined surface, crucial for parts requiring low friction or specific aesthetic standards.

– Material Integrity: Grinding strengthens steel by refining its grain structure, leading to enhanced durability and performance.

– Versatility: Suitable for various steel types and applications, from automotive parts to industrial machinery.

– Cost-Effectiveness: Reduces material waste and extends the lifespan of steel products, optimizing manufacturing costs.

Steel grinding involves various processes to enhance the surface finish and achieve precise dimensions. It is widely used in manufacturing for its efficiency and ability to handle tough materials.

Key features of steel grinding include:

– Surface Finish: Provides a smooth, high-quality finish on steel parts.

– Precision: Ensures tight tolerances and precise measurements.

– Versatility: Suitable for a range of steel types and hardness levels.

– Speed: Offers rapid material removal rates.

– Durability: Extends the lifespan of tools and components.

– Cost-Effectiveness: Reduces material waste and increases efficiency.

– Customizability: Allows for specialized shapes and contours.

– Consistency: Maintains uniformity across multiple parts.

SourcifyChina specializes in providing high-quality custom steel grinding products tailored to meet the specific needs of various industries. With advanced manufacturing techniques, they ensure precision and durability in every product.

Their extensive range includes grinding balls, rods, and liners, crafted to enhance performance and longevity. By utilizing top-grade steel, they guarantee reliability and efficiency in diverse applications, from mining to cement production.

SourcifyChina prides itself on its ability to deliver bespoke solutions. They collaborate closely with clients to understand their unique requirements, ensuring every product meets stringent quality standards.

Numerous successful projects testify to SourcifyChina’s commitment to excellence and customer satisfaction. Their expertise in custom steel grinding fosters innovation, helping clients achieve optimal operational efficiency.

In conclusion, SourcifyChina is a trusted partner for those seeking top-notch steel grinding products and bespoke solutions. Their dedication to quality and customer needs makes them a leader in the industry, driving success in every project they undertake.

SourcifyChina is a leading company specializing in steel grinding products and services. With a focus on high-quality materials and advanced manufacturing techniques, the company serves a diverse range of industries, including mining, construction, and metal fabrication. SourcifyChina prides itself on its ability to deliver precision-engineered grinding solutions that enhance efficiency and performance. The company’s product portfolio includes grinding balls, rods, and other wear-resistant components, all designed to withstand the rigors of heavy industrial use. Committed to sustainability and innovation, SourcifyChina integrates environmentally friendly practices in its operations while continuously investing in research and development to stay ahead of market trends. Its dedication to customer satisfaction is evident in its tailored services, ensuring each client’s unique needs are met with customized solutions and timely delivery. As a trusted partner in the steel grinding sector, SourcifyChina is known for its reliability, technical expertise, and commitment to excellence.

Steel grinding plays a crucial role in the aerospace industry by ensuring the precision and durability of components. Aircraft components, such as turbine blades, landing gears, and structural parts, require extremely tight tolerances and impeccable surface finishes to function correctly and safely under extreme conditions. Steel grinding processes, including cylindrical, surface, and centerless grinding, achieve the necessary precision and surface integrity, reducing the risk of fatigue and failure. Additionally, advanced grinding techniques are employed to work with high-strength, heat-resistant alloys used in jet engines and other critical aerospace components, ensuring they meet stringent industry standards for performance and safety.

In the defense and marine sectors, steel grinding is essential for manufacturing robust and reliable equipment. Defense applications, including the production of armored vehicles, firearms, and missile components, rely on steel grinding to achieve high levels of accuracy and surface quality, ensuring optimal performance and longevity in the field. In the marine industry, steel grinding is vital for fabricating ship hulls, propellers, and other essential parts that must withstand harsh maritime environments. Precision grinding ensures these components have the necessary strength and corrosion resistance to endure prolonged exposure to seawater and extreme mechanical stresses. Overall, steel grinding supports the production of durable, high-performance components critical to the aerospace, defense, and marine industries.

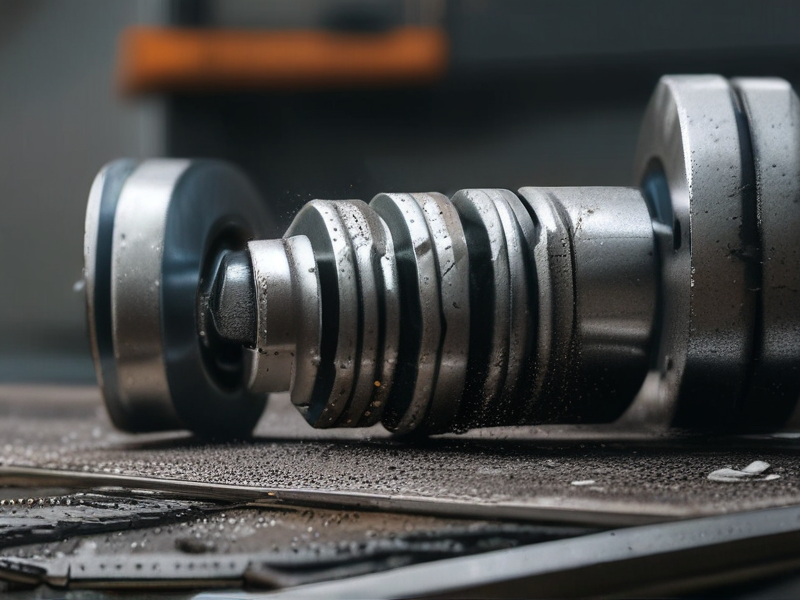

Steel grinding is pivotal in the automotive industry, where precision and durability are paramount. Engine components, such as crankshafts and camshafts, require meticulous grinding to achieve the exact specifications necessary for optimal performance. The process ensures a high degree of surface finish, which is crucial for reducing friction and wear, thus enhancing the longevity and efficiency of the engine. Additionally, steel grinding is essential in producing transmission parts, bearings, and other critical components that must withstand significant mechanical stress and thermal variations. The ability to create smooth, precise surfaces through grinding directly contributes to the overall reliability and performance of automotive systems.

In the electronics industry, steel grinding is equally crucial, particularly in the manufacturing of devices that demand exacting tolerances and superior surface finishes. For instance, components such as connectors, heat sinks, and casings require precise grinding to ensure proper fit and function within electronic assemblies. High-precision steel grinding enables the production of microelectronic components that are essential in the development of smartphones, computers, and other advanced electronic devices. The process also plays a vital role in fabricating parts for semiconductor manufacturing equipment, where the exactness of ground surfaces can impact the efficiency and yield of semiconductor production. Thus, steel grinding in electronics is instrumental in achieving the high standards of precision and quality required in this technologically advanced field.

Steel grinding plays a crucial role in the construction industry by providing essential materials for building and infrastructure projects. Ground steel is used to produce high-quality reinforcing bars, structural beams, and other components that contribute to the strength and durability of buildings, bridges, and roads. The precision and consistency achieved through steel grinding ensure that these components meet stringent industry standards and safety regulations. Additionally, steel grinding allows for the production of custom-fabricated parts, enabling architects and engineers to design innovative structures with unique shapes and features. This adaptability and reliability make steel grinding indispensable in modern construction practices.

In the energy sector, steel grinding is vital for manufacturing components used in power generation and distribution. High-performance steel parts are necessary for constructing turbines, generators, and other machinery in power plants, whether they utilize fossil fuels, nuclear, or renewable energy sources. The precision of steel grinding ensures these components can withstand extreme pressures, temperatures, and mechanical stresses, enhancing the efficiency and longevity of energy systems. Furthermore, in the realm of renewable energy, steel grinding is essential for producing parts for wind turbines and solar panel frames, where precise and durable components are critical for optimal performance. Overall, steel grinding supports the energy sector’s demand for robust, efficient, and long-lasting materials.

Steel grinding is a critical process in the industrial equipment industry, essential for manufacturing components that require high precision and durability. The process involves the use of abrasive wheels to remove material from steel workpieces, achieving the desired shape and surface finish. This technique is widely used in the production of parts for machinery, automotive components, and heavy equipment, where exact tolerances and smooth surfaces are crucial. Grinding ensures that steel components meet stringent specifications, enhancing their performance and lifespan. High-speed grinding machines and advanced grinding technologies enable manufacturers to produce intricate designs and complex geometries, supporting the development of innovative industrial equipment.

In addition to precision shaping, steel grinding is also employed for surface treatment, improving the functional properties of steel parts. The process can enhance the wear resistance, fatigue strength, and overall durability of components, making them suitable for demanding industrial applications. For example, ground steel parts are commonly used in gears, bearings, and engine components, where they must withstand high stress and friction. Furthermore, grinding can remove surface defects and residual stresses from previous manufacturing stages, contributing to the reliability and safety of the final products. As the industrial equipment industry continues to evolve, the application of steel grinding remains a cornerstone, enabling the production of high-quality, high-performance parts essential for modern industrial operations.

Steel grinding plays a critical role in the manufacturing of medical devices, particularly in ensuring the precision and smoothness required for surgical instruments and implants. The process involves removing excess material from stainless steel parts to achieve the desired dimensions and surface finish. This precision is crucial in medical applications, where even the slightest imperfection can lead to complications or reduced functionality. For instance, surgical scalpels, scissors, and forceps must have impeccably sharp and smooth edges to perform effectively during procedures. Grinding ensures these instruments meet stringent industry standards, enhancing their reliability and safety in medical settings.

Moreover, the grinding of steel is essential in producing orthopedic implants, such as hip and knee replacements. These implants require exact specifications to fit seamlessly with the patient’s anatomy, and a smooth finish to prevent wear and irritation within the body. Advanced grinding techniques, including CNC grinding and electrochemical grinding, allow manufacturers to produce these components with high precision and consistency. By using these methods, medical device manufacturers can achieve the tight tolerances and superior surface quality needed to ensure that implants function properly and have a long lifespan, ultimately contributing to better patient outcomes.

Steel grinding is a critical process in machining and manufacturing, essential for creating precision components with fine surface finishes and tight tolerances. This process involves the use of grinding wheels made from various abrasive materials, such as aluminum oxide or silicon carbide, to remove material from steel workpieces through high-speed abrasive action. Steel grinding is employed in several applications, including the production of automotive parts, aerospace components, and industrial machinery. By achieving precise dimensions and smooth finishes, steel grinding ensures that parts meet strict specifications and perform reliably in their respective applications.

In manufacturing, steel grinding is used to enhance the durability and performance of steel components. It is a vital step in the finishing process, often following initial machining operations such as turning or milling. Grinding can correct any slight distortions or surface imperfections left by these preceding processes. Additionally, it is employed in the production of tools and dies, ensuring they possess the necessary hardness and surface integrity for extended use. Through techniques like cylindrical grinding, surface grinding, and centerless grinding, manufacturers can produce components that exhibit superior wear resistance and dimensional accuracy, which are essential for high-stress environments. The versatility and precision of steel grinding make it indispensable in modern manufacturing, contributing significantly to the production of high-quality, reliable steel parts.

Q: What types of steel grinding services does SourcifyChina offer?

A: SourcifyChina offers precision surface grinding, cylindrical grinding, and centerless grinding services for various steel types, ensuring high-quality finishes and tight tolerances.

Q: What materials can SourcifyChina handle?

A: We specialize in grinding a wide range of steel materials, including carbon steel, alloy steel, stainless steel, and tool steel, catering to diverse industrial needs.

Q: What is the typical lead time for steel grinding orders?

A: Lead times vary depending on the project’s complexity and quantity. However, standard orders are usually completed within 2-4 weeks.

Q: How does SourcifyChina ensure quality in steel grinding?

A: We adhere to strict quality control protocols, utilizing advanced machinery and inspection tools to meet industry standards and customer specifications.

Q: Can SourcifyChina handle custom grinding projects?

A: Yes, we provide customized grinding solutions tailored to specific requirements. Clients can submit detailed drawings and specifications for bespoke services.

Q: What is the maximum grinding capacity?

A: Our grinding equipment can handle workpieces up to 1 meter in length and 500 kg in weight, accommodating a wide range of sizes.

Q: What surface finishes can be achieved?

A: We can achieve surface finishes as fine as Ra 0.2 micrometers, ensuring smooth and precise finishes suitable for high-performance applications.

Q: Does SourcifyChina offer any additional services besides grinding?

A: Yes, we offer complementary services such as heat treatment, coating, and machining, providing a one-stop solution for our clients.

Q: How can I get a quote for my project?

A: To receive a quote, please contact us through our website or email, providing detailed information about your project, including material, dimensions, and required tolerances.

Q: What are the payment terms?

A: Our standard payment terms are 30% deposit upon order confirmation and 70% balance before shipment. We also accept various payment methods for convenience.

For more information or specific inquiries, please contact our customer support team.

When considering steel grinding manufacturing from a factory like SourcifyChina, there are several key tips to ensure a successful partnership and high-quality output.

1. Verify Capabilities and Certifications: Ensure the factory has the necessary certifications such as ISO 9001 to guarantee quality management. Verify their capabilities in producing various types of grinding steel and their adherence to industry standards.

2. Material Quality: Inquire about the source of their raw materials. High-quality grinding steel typically starts with refined raw materials. It’s crucial that the steel grades they use are suitable for your specific needs.

3. Precision and Tolerances: Discuss the precision and tolerances they can achieve. Precision is vital for grinding steel to ensure durability and performance. Make sure the factory can deliver the specific tolerances required for your project.

4. Technology and Equipment: Assess the technology and equipment the factory uses. Advanced machinery and up-to-date technology can significantly impact the quality and efficiency of the grinding process.

5. Sample Requests: Always request samples before placing large orders. This allows you to evaluate the quality firsthand and ensure it meets your standards.

6. Lead Times and Capacity: Understand their lead times and production capacity. Reliable turnaround times are essential to keep your supply chain running smoothly without delays.

7. Quality Control: Ensure the factory has a robust quality control process. Regular inspections and testing during different stages of production help maintain consistent quality.

8. Communication: Establish clear communication channels. Effective communication can prevent misunderstandings and ensure your requirements are precisely met.

9. Costing and Payment Terms: Get detailed quotes that include all potential costs, such as shipping, customs, and any other fees. Negotiate payment terms that are feasible for both parties.

10. References and Reviews: Seek references or reviews from other clients to gauge the factory’s reliability and performance history.

By following these tips, partnering with SourcifyChina for steel grinding manufacturing can be both fruitful and efficient.

Q1: What types of steel grinding products does SourcifyChina offer?

A1: SourcifyChina provides a wide range of steel grinding products, including grinding balls, rods, cylpebs, and other custom grinding media. These products cater to various industries such as mining, cement, and power plants.

Q2: What are the material specifications available for steel grinding products?

A2: The steel grinding products from SourcifyChina are available in various material specifications, including high carbon, chrome alloy, and stainless steel. Customers can select the material based on their specific application requirements.

Q3: Can SourcifyChina customize steel grinding products?

A3: Yes, SourcifyChina offers customization services for steel grinding products. Customers can specify dimensions, hardness, and other properties to meet their unique needs.

Q4: What is the minimum order quantity (MOQ) for steel grinding products?

A4: The MOQ varies depending on the product type and specifications. Typically, the MOQ is around 10 tons, but it can be adjusted based on specific customer needs.

Q5: How does SourcifyChina ensure the quality of their steel grinding products?

A5: SourcifyChina employs strict quality control measures, including raw material inspection, production process monitoring, and final product testing. They adhere to international standards to ensure high-quality products.

Q6: What is the lead time for steel grinding orders?

A6: The lead time depends on the order size and customization requirements. Generally, it ranges from 4 to 6 weeks after the order confirmation.

Q7: Does SourcifyChina provide samples before placing a bulk order?

A7: Yes, SourcifyChina can provide samples for evaluation. Customers can request samples to verify the product quality and suitability before placing a bulk order.

Q8: What payment terms does SourcifyChina accept?

A8: SourcifyChina accepts various payment terms, including T/T (Telegraphic Transfer), L/C (Letter of Credit), and other negotiable terms based on the customer’s preference and order volume.

Q9: How can I place an order with SourcifyChina?

A9: Orders can be placed by contacting SourcifyChina’s sales team through their official website or email. Detailed specifications and requirements should be provided to facilitate a smooth ordering process.

Q10: Does SourcifyChina offer after-sales support?

A10: Yes, SourcifyChina provides comprehensive after-sales support, including technical assistance, product maintenance advice, and addressing any issues that may arise post-purchase.

When sourcing “steel grinding” from a factory like SourcifyChina, consider the following tips to ensure a smooth and effective procurement process:

1. Define Your Requirements: Clearly specify the steel grade, dimensions, tolerance, and finishing requirements. Precise details help avoid misunderstandings and ensure you get exactly what you need.

2. Due Diligence: Research SourcifyChina and verify their credibility. Look for reviews, testimonials, and industry certifications. A reliable supplier often has ISO certification and positive client feedback.

3. Request Samples: Before placing a large order, ask for samples. Assess the quality of the steel grinding to ensure it meets your standards and requirements.

4. Communication: Maintain clear and consistent communication. Use detailed emails and video calls. Language barriers can be challenging, so being explicit and confirming details is crucial.

5. Negotiate Terms: Discuss payment terms, lead times, and delivery schedules. Ensure these are clearly defined in the contract. Consider payment methods like a letter of credit (LC) for added security.

6. Quality Assurance: Inquire about the factory’s quality control processes. Regular quality checks, third-party inspections, and compliance with industry standards are essential.

7. Sample Approval: After receiving and approving samples, request a pre-production sample to confirm specifications before mass production begins.

8. Logistics and Freight: Understand the logistics involved, including Incoterms (FOB, CIF, etc.). Factor in shipping costs, customs duties, and potential delays.

9. Build a Relationship: Establish a good rapport with the supplier. A strong relationship can lead to better terms, priority service, and smoother transactions in the future.

10. Legal Protection: Ensure all agreements are documented. Use contracts to protect your interests, specifying terms for quality, delivery, and dispute resolution.

By following these tips, you’ll enhance your chances of a successful and efficient experience sourcing steel grinding from SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.