Reliable Steel Heat Treating Solutions by SourcifyChina: Your Trusted Factory Partner

Experience unparalleled expertise with SourcifyChina’s reliable steel heat treating services. As a trusted factory partner, we ensure top-quality processes and exceptional results, meeting all your industrial needs with precision and efficiency.

Choosing SourcifyChina Factory for purchasing steel heat treating from China offers unparalleled quality and reliability. With years of expertise, SourcifyChina ensures that every product meets international standards, providing buyers with confidence in their purchases.

The factory’s advanced technology and skilled workforce guarantee precision in heat treatment processes. This results in steel products with enhanced durability and performance, meeting diverse industrial needs.

Additionally, SourcifyChina’s commitment to customer satisfaction includes excellent after-sales service and support. Their dedicated team assists buyers from order placement to delivery, ensuring a seamless purchasing experience.

In summary, SourcifyChina Factory combines quality, technology, and customer-centric services, making it the ideal choice for buyers seeking superior steel heat treating solutions from China.

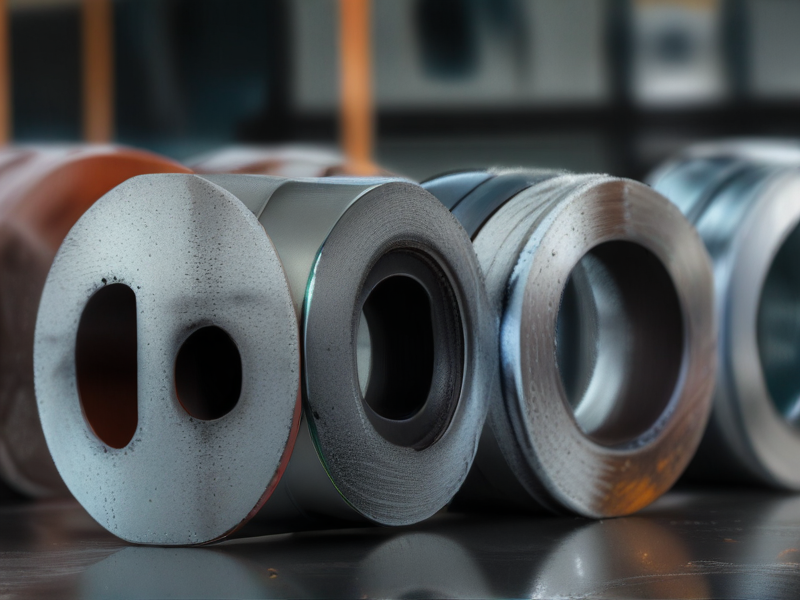

Steel heat treating involves processes like annealing, quenching, and tempering to alter the physical and mechanical properties of steel, enhancing its strength, hardness, and durability for various applications.

– Annealing: Softens steel, improving ductility and reducing internal stresses.

– Quenching: Rapid cooling to increase hardness and strength.

– Tempering: Reduces brittleness after quenching, improving toughness.

– Case Hardening: Hardens the surface while maintaining a softer core, suitable for wear-resistant applications.

– Normalizing: Refines grain structure, improving toughness and strength.

– Stress Relieving: Reduces residual stresses without significant alteration of the steel’s structure.

These processes are critical in manufacturing, toolmaking, and construction, providing tailored material properties for specific uses.

Steel heat treating is a crucial process that enhances the mechanical properties of steel, including hardness, strength, and durability, making it suitable for various industrial applications.

– Aerospace: Improved fatigue resistance and strength for aircraft components.

– Automotive: Enhanced wear resistance and hardness for gears and engine parts.

– Construction: Increased tensile strength and durability for structural steel.

– Tooling: Optimized hardness and strength for cutting tools and molds.

– Oil and Gas: Improved toughness and corrosion resistance for drilling equipment.

– Medical: Precision and wear resistance in surgical instruments.

– Defense: Enhanced mechanical properties for military-grade hardware.

– Machinery: Improved performance and longevity for heavy machinery parts.

– Consumer Goods: Enhanced durability for high-end kitchen knives and tools.

“SourcifyChina” specializes in steel heat treating, a process critical for enhancing the mechanical properties of steel. This involves controlled heating and cooling to alter the microstructure, improving hardness, strength, and ductility.

The company employs various heat treating methods, including annealing, quenching, and tempering. Annealing reduces hardness, increasing ductility, while quenching involves rapid cooling to enhance strength. Tempering adjusts the hardness and toughness post-quenching.

SourcifyChina ensures precise control over the heat treating process, utilizing advanced technology and equipment. This precision guarantees consistent results, meeting stringent industry standards and specific customer requirements.

Their expertise extends to treating different steel grades, catering to diverse applications such as automotive, construction, and manufacturing. SourcifyChina’s comprehensive approach to steel heat treating ensures high-quality, reliable products tailored to meet various industrial needs.

SourcifyChina utilizes an advanced quality control manufacturing process in its steel heat treating operations. The procedure starts with raw material inspection, ensuring only premium-grade steel is selected.

Next, precise machining and pre-treatment processes are applied to prepare the steel for heat treating. This stage is critical for achieving uniformity in the final product’s mechanical properties.

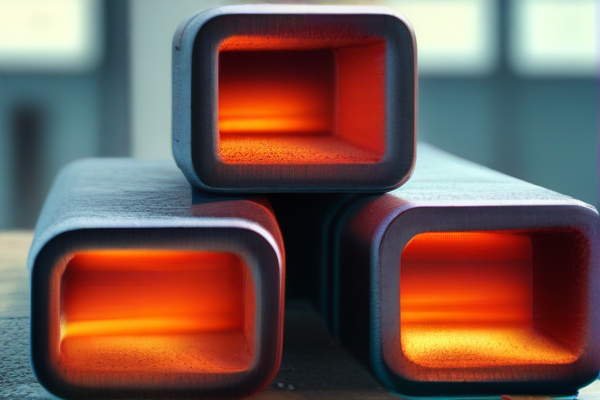

The steel then undergoes carefully controlled heating and cooling cycles. These cycles are closely monitored and adjusted in real-time using state-of-the-art equipment to maintain exact temperature specifications and enhance material strength.

Post-heat treatment, rigorous testing is conducted to check for hardness, tensile strength, and other critical characteristics. Non-destructive testing methods, such as ultrasonic and magnetic-particle inspections, ensure internal and surface integrity without damaging the steel.

SourcifyChina also emphasizes continuous process improvements. Feedback from each production run is analyzed to identify areas for refinement, fostering a culture of perpetual quality enhancement.

Finally, detailed documentation and traceability are maintained for each batch. Comprehensive records ensure accountability and ease future references for performance evaluations or client inquiries.

In summary, SourcifyChina’s meticulous quality control in steel heat treating involves stringent raw material selection, precise processing, real-time monitoring, exhaustive testing, continuous improvement, and thorough documentation, guaranteeing top-quality steel products.

SourcifyChina is renowned for its advanced steel heat treating capabilities, offering a comprehensive range of services tailored to meet diverse industrial needs. Their processes include annealing, quenching, and tempering, ensuring optimal hardness and durability for various steel grades.

The company employs state-of-the-art equipment to maintain precise temperature control, achieving consistent results and high-quality outcomes. This technological edge allows them to handle both large-scale production runs and custom projects with equal efficiency.

In addition to traditional heat treating methods, SourcifyChina specializes in vacuum heat treating. This process minimizes oxidation and contamination, resulting in superior surface quality and mechanical properties of the treated steel.

Their experienced team of metallurgists and engineers provides expert guidance throughout the heat treating process, from initial consultation to final inspection. This ensures that all treated components meet or exceed customer specifications and industry standards.

Furthermore, SourcifyChina places a strong emphasis on sustainability and environmental responsibility. They employ energy-efficient technologies and adhere to stringent environmental regulations, reducing their carbon footprint while delivering exceptional service.

Overall, SourcifyChina’s steel heat treating capabilities stand out due to their combination of advanced technology, skilled expertise, and commitment to quality and sustainability. This makes them a preferred partner for industries requiring reliable and precise steel treatment solutions.

Steel heat treating is a process that enhances the physical and mechanical properties of steel, making it more suitable for various applications. It involves heating and cooling steel to achieve desired hardness, strength, and ductility.

– Increased Hardness: Heat treating can significantly increase the hardness of steel, making it more resistant to wear and abrasion.

– Improved Strength: The process enhances the tensile strength of steel, allowing it to withstand greater loads and stresses.

– Enhanced Ductility: Heat treating improves ductility, making steel more pliable and less prone to cracking under stress.

– Stress Relief: It reduces internal stresses that can cause deformation and failure over time.

– Better Machinability: Treated steel is easier to machine, reducing tool wear and manufacturing costs.

– Corrosion Resistance: Certain heat treatments can improve the corrosion resistance of steel, extending its lifespan.

– Tailored Properties: Heat treating allows for customization of steel properties to meet specific engineering requirements.

– Uniform Microstructure: The process creates a more uniform and refined microstructure, enhancing overall performance.

– Increased Toughness: Treated steel exhibits better toughness, making it more resilient to impact and shock loading.

Overall, heat treating optimizes steel for specific applications, ensuring reliability and durability in demanding environments.

Steel heat treating is a critical process used to alter the physical and mechanical properties of steel for various applications. Below are some key features of this process:

– Hardening: Increases steel’s hardness by heating to a high temperature and then rapidly cooling (quenching).

– Tempering: Follows hardening to reduce brittleness, by re-heating steel to a lower temperature.

– Annealing: Softens steel, improves ductility, and relieves internal stresses by heating and slowly cooling.

– Normalizing: Refines grain structure and improves toughness by heating above the critical temperature and air cooling.

– Case Hardening: Hardens only the surface layer, leaving the core tough and ductile, through methods like carburizing or nitriding.

– Stress Relieving: Minimizes residual stresses without significantly altering the mechanical properties by heating to a moderate temperature and air cooling.

– Austempering: Enhances toughness and reduces distortion by quenching in a bainitic temperature range.

– Martempering: Reduces thermal stress and distortion by quenching in a medium-temperature bath before final cooling.

– Cryogenic Treatment: Further strengthens steel by cooling to cryogenic temperatures, often used for high-performance applications.

These processes are essential for tailoring properties like hardness, toughness, and ductility to meet specific engineering requirements.

SourcifyChina specializes in custom steel heat treating, providing tailored solutions that meet diverse industry needs. Using advanced technology, they ensure each product and project adheres to exact specifications.

They take pride in delivering comprehensive heat treatment services, including annealing, quenching, and tempering. These processes enhance the steel’s physical properties, ensuring durability and reliability for various applications.

Their experienced team collaborates closely with clients to design and implement bespoke heat treatment processes. This personalized approach guarantees optimal results and high-quality finished products that fit unique project requirements.

SourcifyChina ensures rigorous quality control at every stage of production. Employing state-of-the-art testing methods, they confirm that treated steels meet stringent industry standards, offering customers unmatched assurance.

Flexibility is key for SourcifyChina. From small batch orders to large-scale productions, they accommodate different project sizes and timelines efficiently. This adaptability makes them a preferred partner for businesses seeking reliable and efficient steel heat treating services.

Their commitment to innovation and excellence is evident in their continuous investment in cutting-edge technologies and training. This dedication keeps them at the forefront of the steel heat treating industry, delivering superior value to clients.

In conclusion, SourcifyChina stands out in the realm of custom steel heat treating by providing expert services tailored to specific industrial needs. Their unwavering focus on quality, precision, and customer satisfaction ensures they remain a trusted partner in delivering high-performance steel products.

SourcifyChina Steel Heat Treating is a prominent company specializing in the heat treatment of steel, catering primarily to the Chinese market. With a strong emphasis on quality and precision, the company offers a range of heat-treating services including annealing, quenching, tempering, and case hardening. SourcifyChina employs state-of-the-art technology and advanced equipment to ensure the mechanical properties and durability of steel products meet rigorous industry standards. Their team of experienced metallurgists and engineers works closely with clients to provide customized solutions tailored to specific needs, ensuring optimal performance of the treated steel. Committed to sustainability, SourcifyChina also integrates eco-friendly practices into their processes, reducing energy consumption and minimizing environmental impact. By continuously innovating and maintaining high standards, SourcifyChina has established itself as a trusted partner in the steel manufacturing and treatment industry, known for delivering reliable and high-quality services.

Steel heat treating is a vital process in the aerospace industry as it significantly enhances the mechanical properties of steel components used in aircraft and spacecraft. Through controlled heating and cooling cycles, heat treating optimizes the alloy’s strength, hardness, and wear resistance, which is critical for components exposed to high stress, extreme temperatures, and corrosive environments. Landing gear, engine parts, and structural elements of the airframe undergo various heat treatments to ensure they meet stringent safety and performance standards. The process not only prolongs the lifespan of these parts but also maintains their integrity, ensuring reliable operation during demanding flight conditions and extended missions.

In the defense and marine industries, steel heat treating is equally crucial. For defense applications, components such as armor plating, weaponry, and vehicle parts must possess superior toughness and resilience. Heat treating procedures like quenching and tempering make the steel harder and more resistant to impact, providing better protection and performance on the battlefield. Within the marine industry, ships, submarines, and offshore structures benefit from heat-treated steel for its enhanced strength and resistance to corrosion and fatigue. These enhancements are essential to withstand the harsh marine environment, including saltwater corrosion and the mechanical stresses of constant wave impact, ensuring the durability and stability of critical marine infrastructure over prolonged periods.

Steel heat treating is a pivotal process in the automotive industry, enhancing the performance and durability of critical components. By altering the microstructure of steel through controlled heating and cooling, manufacturers can significantly improve attributes like hardness, toughness, and wear resistance. One prominent application is in the production of gears and crankshafts, which endure high stress and demand exceptional fatigue resistance. Heat treating processes such as carburizing, quenching, and tempering enable these components to withstand the rigors of engine operation and transmission systems. Additionally, heat-treated steels find usage in suspension components and body panels, contributing to vehicle safety and structural integrity.

In the electronics industry, steel heat treating plays a crucial role in ensuring the reliability and longevity of various devices and equipment. Electronic enclosures, often made from steel, undergo heat treatment to enhance their resistance to corrosion and improve their mechanical properties, ensuring they protect sensitive internal components from environmental hazards. Heat-treated steel is also integral in the manufacture of connectors, springs, and other small but critical parts within electronic devices. These components must maintain consistent performance under repeated mechanical stress, thermal cycling, and exposure to different environments. By applying precise heat treatment techniques, manufacturers can optimize the physical properties of steel to meet the stringent demands of modern electronic applications.

Steel heat treating is an essential process in construction applications due to its significant impact on the mechanical properties of steel, making it versatile for various structural uses. Heat treating, which involves controlled heating and cooling of steel, alters its microstructure to enhance attributes such as strength, hardness, ductility, and toughness. This process is pivotal in producing structural beams, columns, and reinforcements that need to withstand high loads and stresses in buildings, bridges, and other infrastructure projects. For instance, quenching and tempering treatments yield high-strength, wear-resistant structural components that can endure heavy wear and harsh environmental conditions, thereby ensuring longevity and safety in construction projects.

In the energy sector, steel heat treating is similarly crucial, particularly in the manufacturing of components for power generation, transmission, and distribution systems. The demand for robust and durable materials in energy applications is high, given the extreme environments and stressors like high temperatures and pressures encountered in power plants, oil rigs, and wind turbines. Heat-treating processes such as carburizing and annealing enhance the performance characteristics of steel, ensuring it can sustain prolonged operational periods without degradation. For example, turbine blades, pipeline components, and drilling equipment, often subjected to immense thermal and mechanical stresses, rely on heat-treated steel to maintain structural integrity and operational efficiency, minimizing the risk of failure and downtime while optimizing energy production and distribution.

The industrial equipment industry heavily relies on steel heat treating to enhance the mechanical properties of various components, thereby ensuring their durability and performance. Heat treating involves controlled heating and cooling processes that alter the microstructure of steel to achieve desired hardness, strength, and resistance to wear and corrosion. For example, gears, shafts, and bearings, which are integral parts of heavy machinery, undergo heat treating processes such as annealing, quenching, and tempering. These processes refine the grain structure of the steel, eliminating internal stresses and improving toughness, which extends the lifespan of the equipment and reduces maintenance costs. The ability to finely tune material properties through heat treatment allows manufacturers to meet stringent industry standards and operate effectively under high-stress conditions.

In addition to enhancing mechanical properties, steel heat treating also improves machinability and facilitates the fabrication of complex shapes and components. Processes like case hardening can create a hard outer surface while maintaining a softer, ductile core, which is particularly beneficial for components that require a combination of wear resistance and toughness. This balance between hardness and flexibility is crucial for parts subjected to heavy loads and continuous operations, such as those found in construction equipment, automotive manufacturing, and power generation. The precision and control offered by modern heat treating techniques enable the industrial equipment industry to innovate and adapt to demanding applications, ensuring machines operate efficiently and reliably under diverse working environments. By leveraging advanced heat treating processes, the industry continues to push the boundaries of material performance, driving advancements in both productivity and technological capabilities.

The application of steel heat treating in the medical device industry is pivotal for ensuring the performance, safety, and longevity of surgical instruments and implants. Heat treating processes such as quenching, tempering, and annealing alter the microstructure of steel, enhancing its mechanical properties like hardness, strength, and resistance to wear and corrosion. This is particularly crucial for medical devices that must withstand rigorous sterilization procedures and repetitive use in demanding environments. For instance, surgical scalpels, orthopedic screws, and dental tools benefit from these heat treatments as they enhance reliability and precision, reducing the likelihood of breakage or degradation during critical medical procedures.

Moreover, the customization of steel properties through heat treating allows for the development of specialized medical devices tailored to specific patient needs. Devices like stents, prosthetic joints, and dental implants require precise mechanical properties to perform optimally within the human body. Heat treating can imbue these steel components with required characteristics such as enhanced biocompatibility and fatigue resistance, ensuring that they function seamlessly over prolonged periods. By leveraging advanced heat treatment techniques, the medical device industry can consistently produce high-quality, durable, and safe devices that significantly improve patient outcomes and overall healthcare quality.

Steel heat treating plays a pivotal role in the machining and manufacturing industries, fundamentally enhancing the material properties required for various applications. Through processes like annealing, quenching, and tempering, heat treatment alters the microstructure of steel, imparting desirable characteristics such as increased hardness, improved strength, and better wear resistance. These properties are critical for components that must withstand high-stress environments, including automotive parts, aerospace components, and industrial machinery. By carefully controlling the heating and cooling processes, manufacturers can tailor the physical and mechanical properties of steel to meet specific performance criteria, thereby ensuring the reliability and longevity of their products.

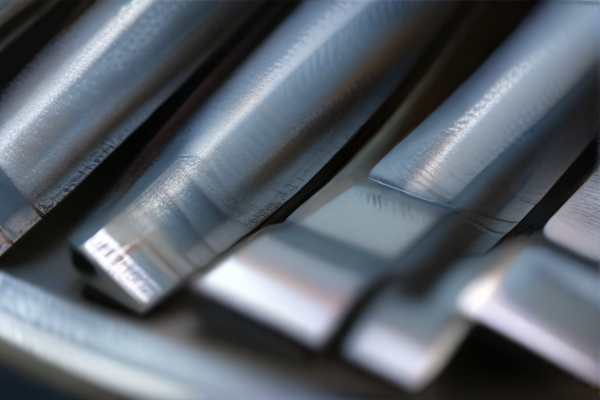

In machining, heat-treated steel offers significant advantages, enabling the production of high-precision components with superior surface finishes and tighter tolerances. The enhanced hardness and reduced ductility of heat-treated steel allow it to withstand the rigors of cutting, drilling, and shaping operations without excessive tool wear or deformation. This results in more efficient production processes, lower operational costs, and higher quality end products. Additionally, the wear resistance conferred by heat treatment extends the operational life of machine parts, reducing maintenance intervals and downtime. In summary, steel heat treating is an indispensable process in machining and manufacturing, driving advancements in material performance and production efficiency.

Sure, here’s a concise FAQ for manufacturing steel heat treating quality work from Sourcify China Factory:

1. What steel heat treating services does Sourcify China Factory offer?

We provide a comprehensive range of steel heat treating services, including annealing, quenching, tempering, normalizing, and carburizing.

2. What types of steel can Sourcify China Factory heat treat?

We can heat treat various types of steel, including carbon steel, alloy steel, stainless steel, and tool steel.

3. What are the benefits of heat treating steel?

Heat treating enhances the mechanical properties of steel, such as hardness, strength, durability, and wear resistance, making it suitable for demanding industrial applications.

4. How does Sourcify ensure the quality of heat treated steel?

We employ advanced equipment, adhere to stringent process controls, and conduct meticulous testing to ensure the highest quality standards for heat treated steel.

5. What testing methods are used to verify heat treating quality?

We use various testing methods such as hardness testing, tensile testing, impact testing, and metallographic analysis to verify the quality of heat treated steel.

6. What are the typical turnaround times for heat treating services?

Turnaround times can vary based on the complexity and volume of the order, but we strive to complete most heat treating services within a standard lead time of 1-2 weeks.

7. Can Sourcify customize heat treating processes to meet specific requirements?

Yes, we offer customizable heat treating processes tailored to the specific needs and requirements of our clients.

8. What industries does Sourcify serve with its heat treating services?

We serve a wide range of industries, including automotive, aerospace, construction, heavy machinery, and tool manufacturing.

9. How can I request a quote or more information about Sourcify’s heat treating services?

To request a quote or more information, please contact our customer service team through our website or email us at [email protected].

10. Where is Sourcify China Factory located?

Our factory is located in a major industrial hub in China, providing easy access to global supply chains and shipping routes.

If you have additional questions not covered here, please feel free to reach out to us directly.

Navigating the complexities of steel heat treating within the context of a manufacturing facility like SourcifyChina requires a precise understanding of both the process and the best operational practices. Here are some essential tips:

1. Material Selection: Ensure you select the right steel grade for your specific application. Different grades respond differently to heat treatment processes, affecting properties like hardness, strength, and wear resistance.

2. Process Control: Maintain strict control over heat treating parameters such as temperature, time, and cooling rate. Consistent monitoring and adjustment help achieve the desired mechanical properties and prevent defects.

3. Quality Assurance: Implement thorough quality checks at every stage. Use techniques like hardness testing, metallographic inspection, and non-destructive testing to verify that the treated steel meets predefined standards.

4. Batch Consistency: Ensure uniformity within production batches. Inconsistent heating or cooling can result in variable material properties, reducing the overall quality and reliability of your products.

5. Equipment Maintenance: Regularly maintain and calibrate heat treating furnaces and associated equipment. Proper upkeep prevents equipment failure, reduces downtime, and ensures consistent performance.

6. Safety Protocols: Adhere to stringent safety measures to protect workers handling high-temperature operations. Proper training and safety gear are crucial.

7. Supplier Collaboration: Work closely with SourcifyChina to understand their capabilities and constraints. Clear communication helps meet specifications and deadlines.

8. Environment Considerations: Utilize eco-friendly practices in disposing of waste materials and managing emissions from the furnaces.

9. Documentation: Keep detailed records of all heat treatment cycles and corresponding results for traceability and continuous improvement.

10. Innovation: Stay updated on the latest advancements in heat treating technologies and methodologies to optimize efficiency and quality.

Employing these strategies will help maximize the benefits of steel heat treating in manufacturing, ensuring high-quality outputs and satisfied clients.

FAQ for Sourcing Steel Heat Treating from SourcifyChina Factory

1. What services does SourcifyChina offer for steel heat treating?

SourcifyChina provides comprehensive steel heat treating services, including annealing, quenching, tempering, carburizing, and nitriding. We cater to various industries such as automotive, aerospace, and heavy machinery.

2. How do I request a quote for my project?

To request a quote, visit our website and fill out the quotation form with details about your project specifications, material grades, desired heat treatment processes, and quantity. Alternatively, you can contact our customer service team directly via email or phone.

3. How long does it take to process an order?

Order processing time depends on the complexity and volume of the project. Typically, it ranges from a few days to a few weeks. Our team will provide an estimated timeline upon reviewing your project details.

4. What quality control measures are in place?

SourcifyChina follows stringent quality control protocols. Our facilities are ISO 9001 certified, and we employ both in-process and final inspections. We also offer documentation and certification for all heat treating processes upon request.

5. Can SourcifyChina handle large volume orders?

Yes, SourcifyChina is equipped to handle both small-scale and large-scale orders. Our advanced facilities and experienced team ensure that we can meet high-volume demands without compromising on quality.

6. Is it possible to get customized heat treatment solutions?

Absolutely. SourcifyChina specializes in customizing heat treatment processes to suit specific requirements. Our technical team will work closely with you to develop tailored solutions that meet your exact needs.

7. What industries does SourcifyChina serve?

We serve a wide range of industries, including automotive, aerospace, construction, heavy machinery, and tool manufacturing. Our expertise in various steel grades and treatments allows us to meet diverse industrial needs.

8. Do you offer shipping and logistics support?

Yes, we provide comprehensive shipping and logistics support to ensure your treated steel products are delivered safely and on time. We can handle both domestic and international shipping requirements.

9. How can I track the progress of my order?

Sourcing steel heat treating services from a specialized factory like SourcifyChina requires careful planning to ensure quality, cost-efficiency, and reliability. Here are some concise tips to guide you:

1. Research and Verification: Begin by thoroughly researching SourcifyChina’s reputation. Check online reviews, industry forums, and ask for references to confirm their credibility and quality standards.

2. Detailed Requirements: Provide detailed specifications for your steel heat treating needs. Include material grades, desired properties, quantities, and specific heat treatment processes like annealing, quenching, or tempering.

3. Sample Testing: Request samples before committing to large orders. Evaluate the samples for adherence to your specifications, and consider third-party testing for unbiased assessment.

4. Certifications: Verify that SourcifyChina holds relevant industry certifications such as ISO 9001, and any specific certifications pertinent to heat treating.

5. Communication: Maintain clear and continuous communication. Ensure there is no language barrier that could lead to misunderstandings about your requirements.

6. Quality Control: Ask about their quality control processes. Establish checkpoints and quality assurance protocols throughout the production process.

7. Lead Times: Confirm lead times and ensure they align with your production schedule. Discuss contingency plans for potential delays.

8. Cost Analysis: Negotiate pricing while considering the overall value, including quality, reliability, and service. Be wary of quotes that seem too low, as they may indicate compromises in quality.

9. Logistics: Plan your logistics carefully. Consider shipping times, import duties, and customs procedures. Work with SourcifyChina to optimize shipping costs and timelines.

10. Contracts and Agreements: Draft clear contracts outlining all agreed-upon details, including specifications, delivery schedules, payment terms, and dispute resolution mechanisms.

By following these tips, you can effectively source steel heat treating services from SourcifyChina, ensuring a successful and productive partnership.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.