Title: “SourcifyChina: Comparing Reliable Steel vs Titanium for Manufacturing Excellence”

For an article of up to 300 words, you can detail the advantages and drawbacks of steel and titanium, focusing on factors such as durability, weight, cost, and specific use cases in manufacturing. Highlight how SourcifyChina can provide reliable sourcing for both materials to meet diverse industry needs.

Choosing SourcifyChina Factory for purchasing steel and titanium from China ensures top-notch quality and competitive pricing. Their dedicated team ensures that all materials meet international standards, guaranteeing reliability and performance.

Additionally, SourcifyChina’s extensive network of suppliers allows for customized solutions tailored to specific needs. This flexibility ensures that buyers obtain the exact specifications they require.

Expertise in both steel and titanium manufacturing means buyers benefit from vast industry knowledge. SourcifyChina Factory supports clients with technical advice, helping them to make informed decisions.

Convenient logistics solutions from SourcifyChina streamline the supply chain. Efficient shipping and handling processes minimize delays, ensuring timely delivery to meet project deadlines.

Lastly, choosing SourcifyChina Factory for purchasing steel and titanium from China means benefiting from exceptional customer service. Their team is committed to addressing any concerns, making the procurement process smooth and stress-free.

Steel and titanium are strong, durable metals with unique properties. Steel is cost-effective and versatile while titanium is lighter, corrosion-resistant, but more expensive.

– Steel Types:

– Carbon Steel: Strong and cost-effective, but prone to rust.

– Stainless Steel: Corrosion-resistant, used in medical and food industries.

– Alloy Steel: Mixed with other metals for added properties like strength and toughness.

– Titanium Types:

– Commercially Pure (CP) Titanium: High corrosion resistance, used in medical implants.

– Titanium Alloys: Mixed with elements like aluminum or vanadium for higher strength and durability.

– Options and Applications:

– Steel:

– Construction: Skyscrapers, bridges, and infrastructure due to its high tensile strength.

– Automotive: Car frames and components for a good balance of strength and weight.

– Tools and Machinery: Widely used due to durability and ease of manufacturing.

– Titanium:

– Aerospace: Aircraft and spacecraft components for strength without added weight.

– Medical: Implants and surgical instruments due to biocompatibility.

– Sports Equipment: High-end, lightweight gear like bicycle frames and golf clubs.

– Comparison:

– Cost:

– Steel: Generally cheaper and widely available.

– Titanium: More expensive due to production costs and properties.

– Weight:

– Steel: Heavier, affecting ease of transport and structure weight.

– Titanium: Approximately 40% lighter than steel.

– Corrosion Resistance:

– Steel: Prone to rust unless treated or alloyed.

– Titanium: Superior corrosion resistance, ideal for harsh environments.

– Strength:

– Steel: High tensile strength.

– Titanium: Comparable to steel but can be stronger when alloyed.

Choosing between steel and titanium involves considering factors like cost, weight, corrosion resistance, and specific application needs.

Steel and titanium are essential metals in various industries due to their distinct properties. Steel is favored for its affordability and ductility, while titanium is valued for its strength-to-weight ratio and corrosion resistance.

– Construction: Steel is commonly used in construction due to its high tensile strength and lower cost.

– Aerospace: Titanium’s lightweight and high strength make it ideal for aerospace applications, including aircraft frames and fasteners.

– Medical: Titanium is biocompatible and used in surgical instruments and implants.

– Automotive: Steel is utilized in vehicle frame construction, while titanium is used in high-performance parts like exhaust systems.

– Marine: Titanium’s corrosion resistance makes it suitable for marine environments and submarine hulls.

– Sports Equipment: Titanium is used in bicycles and golf clubs due to its lightweight nature.

– Industrial Equipment: Steel is essential in manufacturing heavy machinery and tools.

Both metals play crucial roles in their respective applications, balancing cost, performance, and durability.

SourcifyChina offers a detailed comparison of steel and titanium, two commonly used materials in various industries. Steel is an alloy primarily composed of iron and carbon, known for its strength and durability. It’s widely available and cost-effective, making it a popular choice in construction and manufacturing.

In contrast, titanium is a lightweight, corrosion-resistant metal valued in aerospace, military, and medical industries. Its high strength-to-weight ratio and biocompatibility make it ideal for applications requiring durability and lightness. However, titanium is more expensive due to its complex extraction and processing methods.

Steel’s advantages include its ease of production and versatile applications, ranging from infrastructure to automotive parts. It also offers excellent load-bearing capacity, making it suitable for heavy-duty uses. However, it is prone to rust and oxidation, requiring protective coatings or treatments.

Titanium offers superior resistance to corrosion and fatigue, ensuring longer lifespan and lower maintenance costs over time. Despite its higher upfront cost, the benefits of titanium in critical applications often justify its expense. Industries like aerospace prefer titanium for its performance under extreme conditions.

In conclusion, both steel and titanium have unique properties that serve different needs. Steel is favored for its cost-efficiency and widespread availability, suitable for general-purpose applications. Titanium, though pricier, excels where strength, weight, and corrosion resistance are critical. Choosing between them depends on the specific requirements of the project, balancing budget constraints with performance needs.

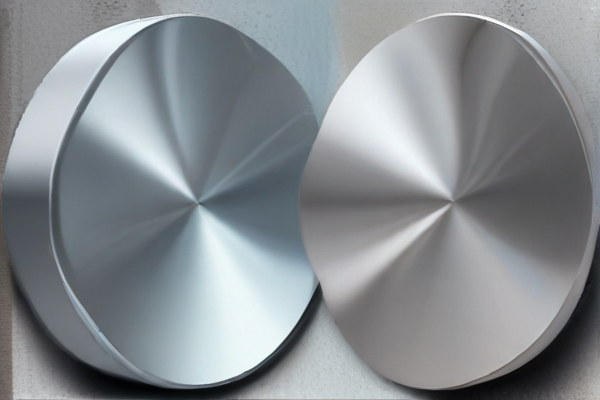

SourcifyChina steers quality control for steel with a regimented process, focusing on raw material inspection, chemical composition analysis, and tensile strength validation. Non-destructive testing (NDT) like ultrasonic and magnetic particle inspection ensures the steel meets stringent quality standards before dispatch.

In titanium production, SourcifyChina places a premium on purity, performing meticulous assessments at each stage. This includes sponge titanium quality checks, remelting processes, and the vacuum arc remelting (VAR) technique, ensuring contamination-free, high-strength titanium alloys.

Quality control mechanisms for both steel and titanium involve rigorous in-process monitoring, with final product inspection including dimensional accuracy, surface finish, and mechanical property verification, ensuring adherence to international standards.

Innovative techniques such as digital twin technology and real-time data analytics optimize the manufacturing process, predicting defects and enhancing efficiency. This commitment to technological integration underscores SourcifyChina’s dedication to excellence.

In essence, SourcifyChina maintains rigorous quality control processes across steel and titanium manufacturing, ensuring high-quality, reliable materials for diverse industrial applications. The blend of traditional methods and advanced technologies cements their position as a leader in the metal manufacturing industry.

SourcifyChina specializes in the procurement of both steel and titanium, offering comprehensive solutions tailored to meet diverse industrial requirements. Steel, known for its versatility and strength, is primarily utilized in construction, automotive, and infrastructure projects. It offers superior durability and cost-effectiveness compared to other metals.

Titanium, on the other hand, is renowned for its exceptional strength-to-weight ratio and corrosion resistance. This makes it ideal for aerospace, medical, and high-performance engineering applications. Titanium’s non-magnetic nature also makes it advantageous in specialized fields like military and electronics.

SourcifyChina leverages global networks and advanced supply chain strategies to ensure timely and cost-efficient delivery of these materials. In the steel sector, the company excels in providing various grades and finishes, enabling customization for specific project needs. This adaptability ensures that clients receive materials that meet stringent quality and regulatory standards.

When it comes to titanium, SourcifyChina’s expertise includes sourcing from leading manufacturers, ensuring the highest quality and compliance with industry standards. The company’s robust logistics and quality control systems further guarantee that clients receive products that match their exact specifications and performance criteria.

By offering streamlined procurement services for both steel and titanium, SourcifyChina ensures that clients from various industries have access to high-quality materials tailored to their specific needs. This dual-specialization not only broadens their market reach but also enhances their capability to meet complex industrial demands efficiently. Their dedication to quality and service excellence makes SourcifyChina a trusted partner in the materials procurement industry.

Steel and titanium are both widely used metals with unique benefits, making them suitable for different applications. Here’s a brief comparison of their advantages:

Benefits of Steel:

– Cost-Effective: Steel is generally more affordable than titanium.

– High Strength: Offers excellent tensile strength and durability.

– Versatility: Can be used in a variety of applications from construction to automotive.

– Weldability: Easier to weld, forge, and fabricate.

– Availability: Widely available and comes in various grades and forms.

– Recyclability: Highly recyclable, which is beneficial for sustainability.

Benefits of Titanium:

– Lightweight: Offers high strength-to-weight ratio, making it ideal for aerospace and sporting goods.

– Corrosion Resistance: Highly resistant to corrosion, even in harsh environments like seawater.

– Biocompatibility: Suitable for medical applications as it is non-toxic and not rejected by the body.

– Thermal Stability: Maintains mechanical properties at elevated temperatures.

– Longevity: Long-lasting, reducing the need for frequent replacements or maintenance.

– Non-Magnetic: Ideal for applications requiring non-magnetic properties.

In summary, steel is cost-effective, highly versatile, and durable, making it suitable for a wide range of applications. Titanium, while more expensive, offers superior strength-to-weight ratio, corrosion resistance, and biocompatibility, making it ideal for specialized industries like aerospace and medical.

Steel and titanium are two versatile metals, each with distinct properties and applications. Steel is known for its affordability and versatility, while titanium is prized for its strength-to-weight ratio and corrosion resistance.

– Durability: Steel is incredibly durable and resistant to impact.

– Affordability: Generally cheaper compared to titanium.

– Versatility: Widely used in construction, automotive, and manufacturing.

– Magnetic: Steel can be magnetic depending on its composition.

– Corrosion: Prone to corrosion unless treated or alloyed.

– Weight: Heavier than titanium, adding more weight to structures.

– Machinability: Easier to work with for cutting, welding, and forming.

– Strength-to-Weight Ratio: Titanium is strong yet lightweight, ideal for aerospace and medical applications.

– Corrosion Resistance: Excellent resistance to corrosion, even in harsh environments.

– Biocompatibility: Safe for medical implants and prosthetics.

– Cost: More expensive due to complex extraction and processing.

– Thermal Resistance: Maintains strength and stability at high temperatures.

– Non-Magnetic: Titanium is non-magnetic, making it suitable for applications requiring this property.

– Fatigue Resistance: High resistance to metal fatigue and cracking.

Choosing between steel and titanium depends largely on the specific requirements of the application, considering factors like cost, weight, durability, and resistance properties.

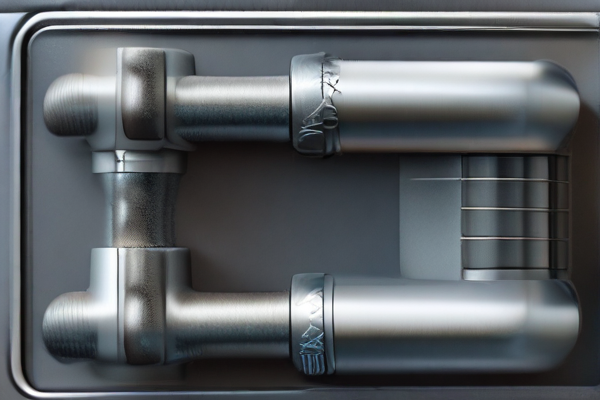

SourcifyChina offers customized products and projects made from both steel and titanium. Steel is renowned for its durability, cost-effectiveness, and widespread application in construction and manufacturing industries. It’s an ideal material for projects requiring strong structural integrity without a hefty price tag.

Titanium, on the other hand, is highly valued for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. These qualities make it suitable for aerospace, medical devices, and high-performance sports equipment. Despite its higher cost, titanium delivers unparalleled performance in demanding applications.

Choosing between steel and titanium largely depends on project needs and budget constraints. While steel is better for cost-sensitive, high-volume projects, titanium excels in specialized, high-performance applications. SourcifyChina helps clients make informed choices, optimizing material selection for each specific project.

To ensure optimum results, SourcifyChina provides in-depth consultations, guiding clients through material benefits and drawbacks. Their expertise in material science fosters efficient decision-making, balancing performance with cost. Whether it’s steel or titanium, the company is committed to delivering top-notch, custom solutions tailored to unique project requirements.

SourcifyChina Steel vs Titanium is an innovative enterprise that specializes in the sourcing and comparison of two pivotal materials—steel and titanium—for a variety of industrial applications. Leveraging their extensive network and deep-rooted expertise in the Chinese manufacturing sector, the company offers a comprehensive suite of services that include material sourcing, quality assurance, and supply chain management. Steel and titanium, both known for their distinctive properties and wide range of uses, are critical in industries ranging from aerospace to construction. SourcifyChina not only provides high-quality steel and titanium but also offers analysis and consultation to help clients determine the most suitable material for their specific project requirements. This unique focus on two fundamental yet contrasting materials positions SourcifyChina as a key player in delivering tailored solutions that optimize both performance and cost-efficiency for businesses worldwide. Through rigorous quality checks and strategic partnerships with reputable manufacturers, the company ensures that clients receive materials that meet stringent international standards. With an unwavering commitment to excellence and customer satisfaction, SourcifyChina Steel vs Titanium stands as a trusted partner in bridging the gap between raw material suppliers and global industries.

Steel and titanium are critical materials in aerospace, defense, and marine applications due to their distinct properties. Steel, known for its high strength, toughness, and durability, is widely used in applications requiring robust structural components. Its relative affordability and ease of manufacturing make it a staple in constructing aircraft frames, naval vessels, and armored vehicles. In marine environments, steel’s resistance to impact and its ability to withstand heavy loads are crucial for shipbuilding and offshore structures. However, steel’s higher density compared to titanium means it adds more weight, which can be a disadvantage in applications where weight savings are critical.

Titanium, on the other hand, offers a superior strength-to-weight ratio and excellent corrosion resistance, making it highly valuable in aerospace and defense sectors where performance and durability are paramount. Its lighter weight compared to steel contributes to fuel efficiency and higher payload capacities in aircraft and spacecraft. Titanium’s ability to withstand extreme temperatures and harsh environments makes it ideal for components like jet engines, airframes, and military equipment exposed to corrosive conditions. In marine applications, titanium’s resistance to seawater corrosion extends the lifespan of submarines, naval ships, and offshore structures, reducing maintenance costs and enhancing operational efficiency. Despite its higher cost and more complex manufacturing processes, the benefits of titanium in critical, high-performance applications often justify its use over steel.

Steel and titanium are both critical materials in the automotive industry, but their distinct properties make them suitable for different applications. Steel is renowned for its affordability, strength, and ease of production, making it a common choice for car frames, body panels, and various engine components. Modern advancements in high-strength, low-alloy (HSLA) steels have improved their performance, offering enhanced durability and crash resistance without significant weight penalties. On the other hand, titanium’s exceptional strength-to-weight ratio and excellent corrosion resistance make it ideal for high-performance and luxury vehicles. Although more expensive, the use of titanium in suspension systems, exhausts, and certain engine parts can significantly reduce vehicle weight, improving fuel efficiency and handling performance in high-end sports cars.

In the realm of electronics, steel and titanium serve specialized functions due to their unique characteristics. Steel is often used in the structural and protective components of electronic devices, such as casings, chassis, and mounting frames. Its robustness and workability make it a reliable choice for safeguarding delicate electronics from physical impacts. Conversely, titanium’s excellent electrical conductivity, coupled with its lightweight and non-magnetic properties, makes it suitable for specific high-performance applications. For instance, titanium is used in the production of connectors, conductive traces for circuit boards, and even high-frequency antennas. Additionally, titanium’s non-reactive nature makes it preferable for medical electronics, where biocompatibility is paramount. The decision between using steel or titanium in electronics often hinges on factors like cost, weight, and specific application requirements.

Steel and titanium are two critical materials in construction, each offering distinct advantages. Steel, known for its immense strength and flexibility, is widely used in the construction of buildings, bridges, and industrial structures. Its capacity to bear heavy loads and resist deformation makes it a reliable choice for high-rise buildings and long-span bridges. Additionally, steel is cost-effective and readily available, making it the go-to material for many large-scale projects. On the other hand, titanium, although significantly more expensive than steel, is valued for its exceptional strength-to-weight ratio and corrosion resistance. This makes titanium particularly useful in challenging environments, such as coastal or chemically aggressive areas, where durability and longevity are critical factors. Its lighter weight can also contribute to reduced foundation requirements and facilitate quicker construction processes under certain conditions.

In the energy sector, both materials have vital applications, leveraging their unique properties. Steel is predominantly employed in constructing pipelines, transmission towers, and wind turbines due to its robustness and ease of fabrication. These energy infrastructures benefit from steel’s tensile strength and reliability over vast operational lifespans. However, titanium plays a pivotal role in specialized energy applications due to its superior corrosion resistance and high-temperature tolerance. It is commonly used in nuclear power plants, desalination plants, and aerospace components involved in energy projects, where materials are subjected to extreme conditions. Titanium’s capacity to withstand such environments without degrading ensures the longevity and safety of these critical energy systems. Despite its higher cost, titanium’s long-term performance benefits often justify its use in high-stress and high-value applications, thereby complementing the more widespread use of steel in conventional energy infrastructure.

In the industrial equipment sector, both steel and titanium play crucial roles due to their distinct mechanical properties and application-specific advantages. Steel, an alloy primarily composed of iron and carbon, is widely valued for its strength, durability, and cost-effectiveness. It is commonly used in the construction of heavy machinery, structural components, and tools that demand high wear resistance and load-bearing capability. For example, stainless steel, which includes chromium to enhance corrosion resistance, is crucial in environments exposed to moisture and chemicals. Its versatility ensures pertinence across various applications, including manufacturing plants, automotive components, and large-scale infrastructure projects. The relative affordability and ease of fabrication of steel further underscore its dominant presence in industrial equipment.

Conversely, titanium, while more expensive, offers exceptional benefits that make it indispensable in specific industrial applications where weight and corrosion resistance are imperative. Titanium boasts a high strength-to-weight ratio, enabling the production of lightweight yet robust components. This makes it particularly valuable in aerospace and marine industries, where reducing weight without compromising strength can significantly enhance performance and fuel efficiency. Additionally, titanium’s superior resistance to corrosion, even in harsh environments such as saltwater or acidic conditions, extends the longevity of equipment and lowers maintenance costs. Consequently, titanium is often employed in applications such as aircraft parts, heat exchangers, and chemical processing equipment, where its advanced properties can justify the higher material investment. Thus, the choice between steel and titanium in the industrial equipment industry is strategically driven by a balance between performance requirements and economic considerations.

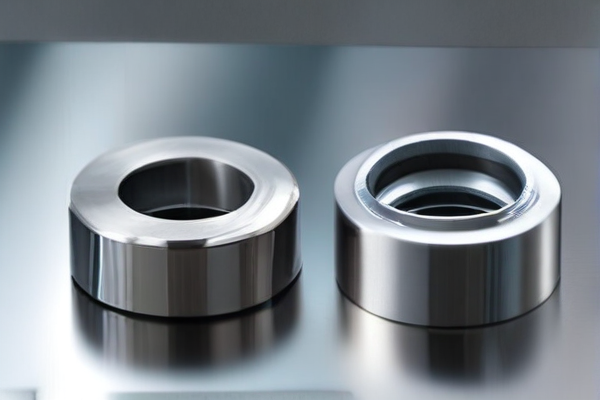

In the realm of medical devices, material selection is pivotal in ensuring the efficacy, safety, and longevity of implants and instruments. Steel, particularly surgical stainless steel, has been a staple in the medical industry due to its excellent mechanical properties, resistance to corrosion, and affordability. It is commonly used for surgical instruments, orthopedic implants like screws and plates, and certain dental applications. Surgical stainless steel owes its utility to its high strength, durability, and ease of sterilization, making it suitable for a wide range of medical applications. However, one of its limitations is its higher density and potential for allergic reactions in some patients due to nickel content.

In contrast, titanium and its alloys have gained prominence for their superior biocompatibility and mechanical properties, making them highly suitable for long-term implants. Titanium’s lower density compared to steel translates to lighter implants, which is particularly advantageous in orthopedics and dental applications where weight reduction can lead to improved patient outcomes and comfort. Moreover, titanium exhibits excellent corrosion resistance and minimizes the risk of adverse reactions with bodily tissues, thus ensuring higher compatibility and durability within the human body. These properties make titanium the material of choice for critical applications like hip and knee replacements, spinal fusion devices, and even cardiovascular stents. Despite titanium’s higher cost, its advantages in terms of biocompatibility and mechanical performance often justify its use in critical and long-term medical applications.

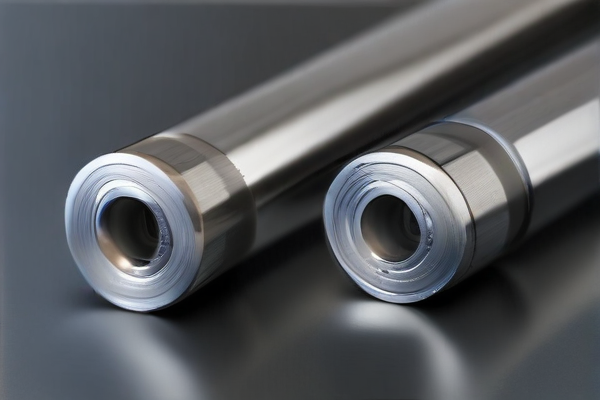

When it comes to machining and manufacturing, steel and titanium present distinct characteristics that cater to different requirements. Steel, an alloy of iron, is favored for its widespread availability, affordability, and ease of machining. Due to its high strength and versatility, steel is extensively used in automotive, construction, and heavy machinery applications. The material’s well-understood properties, coupled with extensive tooling options, make it a reliable choice for complex and high-volume manufacturing processes. However, steel’s density and susceptibility to corrosion can be limiting factors, particularly in applications where weight reduction and environmental resistance are critical.

Titanium, on the other hand, stands out for its exceptional strength-to-weight ratio and corrosion resistance, making it invaluable in high-performance sectors such as aerospace, medical implants, and military equipment. Machining titanium, though, poses significant challenges due to its hardness, low thermal conductivity, and chemical reactivity with cutting tools, resulting in higher costs and decreased tool life. Specialized techniques and tooling, such as using coated carbide tools and implementing low cutting speeds, are required to effectively machine titanium. Despite these challenges, the material’s superior properties can lead to enhanced product performance and longevity, justifying the increased manufacturing investments.

Sure, here’s a concise FAQ comparing steel and titanium quality work from SourcifyChina factory:

1. What are the key differences between steel and titanium in manufacturing?

Steel is known for its strength, durability, and cost-effectiveness, making it ideal for heavy-duty applications. Titanium, while more expensive, offers superior strength-to-weight ratios, corrosion resistance, and biocompatibility, suitable for aerospace, medical, and specialized applications.

2. How do manufacturing processes differ between steel and titanium?

Steel manufacturing typically involves simpler processes like casting, forging, and welding. Titanium requires more specialized techniques due to its high melting point and reactive nature, involving vacuum conditions and inert gas atmospheres to prevent contamination.

3. Which material is more cost-effective for industrial applications?

Steel is generally more cost-effective due to its widespread availability and lower processing costs. However, for applications demanding high strength-to-weight ratios and corrosion resistance, titanium’s benefits may justify its higher costs.

4. How does SourcifyChina ensure quality control for steel and titanium products?

SourcifyChina employs rigorous quality control measures including material certification, precise machining tolerances, non-destructive testing (NDT), and adherence to international standards like ISO, ASTM, and ASME for both steel and titanium products.

5. What are the environmental impacts of using steel versus titanium?

Steel has a higher carbon footprint mainly due to energy-intensive mining and processing. Titanium manufacturing also consumes considerable energy but has lower lifecycle emissions due to its longevity and recyclability. SourcifyChina adopts eco-friendly practices to minimize environmental impact.

6. Are there specific industries where one material is preferred over the other?

Yes, steel is preferred in construction, automotive, and heavy machinery due to its cost and strength. Titanium is favored in aerospace, medical devices, and high-performance sports equipment for its lightweight and corrosion-resistant properties.

7. Can SourcifyChina provide custom alloy compositions for both steel and titanium?

Yes, SourcifyChina offers custom alloy compositions tailored to specific application requirements, ensuring optimal performance and compatibility with client specifications.

8. How does SourcifyChina handle large-scale orders for steel and titanium products?

SourcifyChina has scalable manufacturing capabilities, advanced machinery, and efficient supply chain management to handle large-scale orders, ensuring timely delivery and consistent quality for both steel and titanium products.

When considering “steel vs titanium manufacturing” from a reputable source like SourcifyChina factory, there are several key factors to weigh:

Steel:

1. Strength: High tensile strength, especially in alloyed forms.

2. Cost: Generally cheaper and more accessible.

3. Durability: Good resistance to wear and tear, especially when coated.

4. Weight: Heavier, which can be a drawback for applications requiring lightweight materials.

Titanium:

1. Strength-to-Weight Ratio: Superior to steel; lightweight yet strong.

2. Corrosion Resistance: Excellent, ideal for harsh environments.

3. Biocompatibility: Suitable for medical applications.

4. Cost: Higher material and processing costs.

Steel:

1. Machining: Well-suited for various machining processes; generally easier to work with.

2. Welding: More straightforward and less costly due to lower melting points.

3. Recycling: Widely recycled, thus more sustainable.

Titanium:

1. Machining: More challenging; requires specialized tools and knowledge.

2. Welding: More complex, needing an inert atmosphere to avoid contamination.

3. Recycling: Less commonly recycled and more costly.

Steel is often preferred in construction, automotive, and heavy machinery sectors due to its affordability and strength. Titanium finds its niche in aerospace, medical implants, and high-performance sporting goods, where its lightweight and superior corrosion resistance are essential.

From SourcifyChina, bulk purchasing and streamlined supply chain management can mitigate some cost issues. However, the inherent material and processing costs mean steel often wins in price-sensitive applications, while titanium is justified in high-performance contexts requiring its unique properties.

In summary, choosing between steel and titanium should depend on your specific requirements for strength, weight, corrosion resistance, and budget. SourcifyChina’s expertise can help guide this decision and ensure optimal manufacturing outcomes.

Sure! Here are some Frequently Asked Questions (FAQ) with answers regarding sourcing steel vs. titanium from SourcifyChina factory:

Q: What are the primary differences between steel and titanium?

A: Steel is generally stronger, more malleable, and less expensive compared to titanium. Titanium, however, is lighter, more corrosion-resistant, and biocompatible, making it suitable for specialized applications like aerospace and medical devices.

Q: Which material is more cost-effective for my project?

A: Steel is typically more cost-effective due to its lower material and processing costs. However, titanium may offer long-term savings in applications where weight reduction or corrosion resistance is critical.

Q: What are the lead times for sourcing steel vs. titanium?

A: Lead times can vary based on the complexity and quantity of the order. Generally, titanium may have slightly longer lead times due to its specialized processing requirements. SourcifyChina provides estimated lead times upon request.

Q: How does the weight difference impact my project?

A: Titanium’s weight advantage can be significant for projects that benefit from reduced weight, such as aerospace or transportation. Steel’s higher density provides advantages in applications requiring higher structural strength and durability.

Q: Which material offers better corrosion resistance?

A: Titanium offers superior corrosion resistance compared to steel. This is particularly beneficial for applications exposed to harsh environments or chemicals.

Q: Are there differences in machinability between steel and titanium?

A: Yes, steel is generally easier to machine than titanium. Machining titanium can be more challenging and require specialized equipment and expertise, which SourcifyChina can provide.

Q: Can SourcifyChina provide customized solutions for both materials?

A: Absolutely. SourcifyChina offers tailored solutions for both steel and titanium, including custom alloys, sizes, and finishes to meet specific project requirements.

Q: What industries benefit most from using titanium over steel?

A: Industries such as aerospace, medical devices, military, and high-performance automotive sectors often prefer titanium for its strength-to-weight ratio and corrosion resistance.

Q: How does the environmental impact compare between steel and titanium?

A: Both materials have environmental considerations. Steel production is more energy-intensive but highly recyclable. Titanium production is less widespread but offers benefits such as reduced fuel consumption in applications requiring lightweight materials.

When sourcing steel versus titanium from a factory such as SourcifyChina, consider the following tips:

1. Material Properties and Application: Understand the fundamental differences between steel and titanium. Titanium is lighter, more corrosion-resistant, and stronger in some aspects but is also typically more expensive. Steel, while heavier, is generally more cost-effective and more widely available in various grades.

2. Cost Analysis: Request detailed quotations for both materials, including raw material costs, manufacturing costs, and any additional processing fees. Be sure to compare these against the durability, strength, and weight requirements of your project.

3. Supplier Verification: Ensure SourcifyChina is a reputable supplier. Look for certifications like ISO 9001, and ask for references or case studies demonstrating their experience with both steel and titanium.

4. Minimum Order Quantities (MOQs) and Lead Times: Discuss MOQs and lead times for both materials. Titanium may have higher MOQs and longer lead times compared to steel due to its more complex processing requirements.

5. Quality Assurance: Verify the quality assurance processes for both materials. Ask about testing methods, inspection standards, and certifications that validate the material quality and adherence to specifications.

6. Machining and Fabrication Capabilities: Check the factory’s capabilities in machining, welding, and treating both steel and titanium. Ensure they have the necessary equipment and expertise, as titanium requires different handling compared to steel.

7. Logistics and Shipping: Consider logistics and shipping costs. Titanium’s lower density might reduce shipping costs despite its higher initial material cost. Ensure packaging and handling methods are adequate to prevent damage during transit.

8. Environmental and Sustainability Concerns: If sustainability is a priority, inquire about the factory’s environmental policies and the recyclability of the materials.

By focusing on these aspects, you can make an informed decision that balances cost, quality, and suitability for your specific application.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.

How can I help you? :)