Technology and Applications of steelwork fabrication

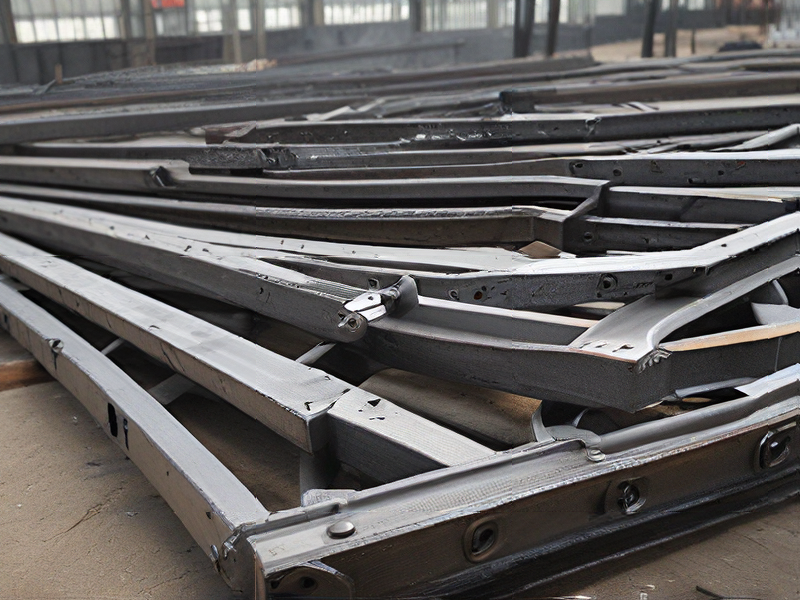

Steelwork fabrication is a vital process in construction and manufacturing, involving the cutting, shaping, and assembly of steel structures to meet specific design requirements. With advancements in technology, the fabrication of steel has become more efficient and precise, significantly enhancing the quality and safety of construction projects.

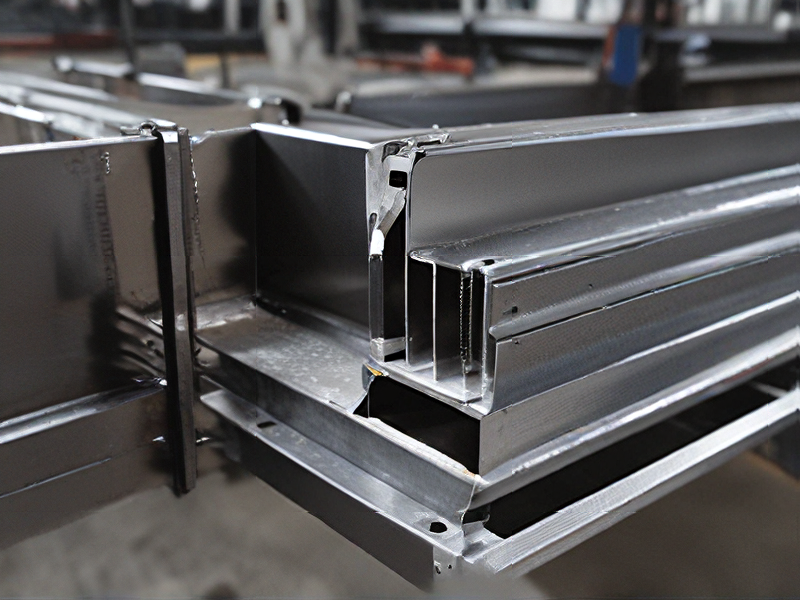

Modern steel fabrication employs technologies such as Computer-Aided Design (CAD) and Computer Numerical Control (CNC) machining. CAD software allows engineers and architects to create detailed 3D models of structures, facilitating visualization and design validation. CNC machines can then interpret these designs to cut and shape steel components with high precision, reducing material waste and increasing productivity.

Additionally, automation and robotics have started to play a substantial role in steel fabrication. Automated processes can enhance the speed of production while minimizing human error. For instance, robotic arms are used for welding, ensuring consistent quality and strength in joints, which is critical for structural integrity.

Steelwork fabrication finds applications across various sectors, including construction (building frames, bridges), automotive (vehicle chassis), shipbuilding (hulls and superstructures), and energy (wind turbine towers, oil rigs). The versatility of steel makes it a preferred choice for projects requiring durability and strength.

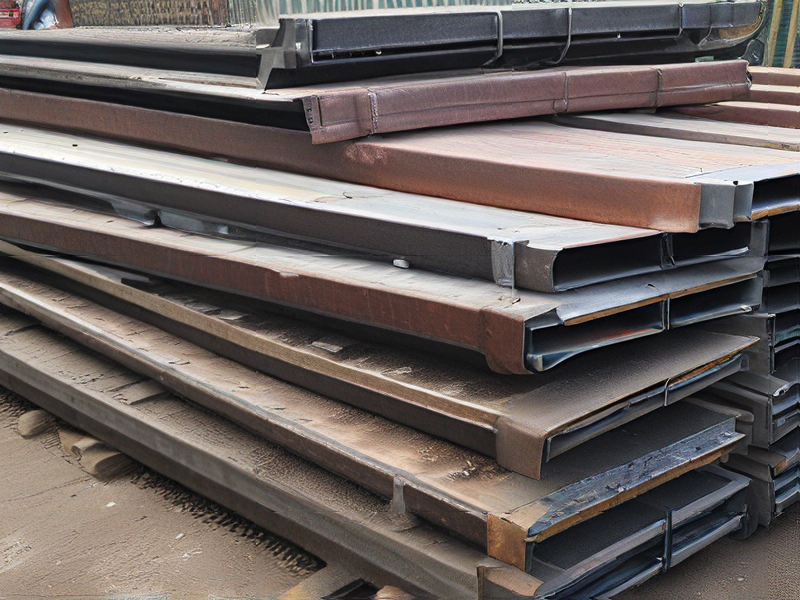

Furthermore, the rise of sustainable practices in steel fabrication, such as using recycled steel and energy-efficient processes, is shaping the future of construction. These innovations not only address environmental concerns but also enhance the overall lifecycle of steel products.

In summary, the technology and applications of steelwork fabrication are crucial to modern engineering. The integration of advanced technologies ensures that the resulting structures are not only robust and reliable but also sustainable, meeting the demands of contemporary society.

Quality Testing Methods for steelwork fabrication and how to control quality

Quality testing methods for steelwork fabrication are essential to ensure structural integrity and performance. Key methods include:

1. Visual Inspection: The first step involves examining the steel for obvious defects such as cracks, warping, or improper welds. Trained inspectors assess joints, surface finish, and dimensions.

2. Non-Destructive Testing (NDT): Techniques like Ultrasonic Testing (UT), Magnetic Particle Testing (MT), and Liquid Penetrant Testing (PT) are employed to detect internal and surface defects without damaging the material. These methods help verify weld integrity and detect surface flaws.

3. Destructive Testing: This includes tensile testing, impact testing, and bend testing. Samples are taken from welds or materials and subjected to stress to determine their mechanical properties, ensuring they meet design specifications.

4. Dimensional Inspection: Using tools like calipers and laser measurement systems, dimensions of cut and fabricated pieces are checked against specifications to ensure accuracy.

5. Material Certification: Ensure all materials are traceable with documentation verifying that they conform to required standards (e.g., ASTM, ISO).

To control quality effectively in steelwork fabrication:

– Establish Quality Control Plans: Define standards and testing protocols upfront based on project requirements.

– Continuous Training: Ensure that staff are well-trained in both inspection techniques and quality standards.

– Supplier Quality Assurance: Vet suppliers and enforce quality standards on materials before they reach the fabrication process.

– Documentation and Traceability: Keep thorough records of inspections, tests, and certifications to facilitate audits and address issues promptly.

– Periodic Surveys and Audits: Regularly assess compliance with quality control measures and detect areas for improvement.

Implementing these methods ensures reliability and safety in steelwork fabrication while maintaining high standards of quality.

Tips for Procurement and Considerations when Purchasing from steelwork fabrication

When procuring services for steelwork fabrication, several key considerations can enhance the purchasing process and ensure optimal outcomes.

1. Clearly Define Specifications: Before initiating procurement, have a well-defined project scope. Detail the dimensions, materials, finishes, and any other relevant technical requirements. This helps in obtaining accurate quotes and minimizes misunderstandings later.

2. Assess Fabricator’s Expertise: Choose a fabricator with proven experience in similar projects. Review their portfolio, ask for references, and evaluate their certifications to ensure they meet industry standards, such as ISO certification.

3. Evaluate Capabilities: Consider the fabricator’s capabilities in terms of machinery, technology, and workforce. Ensure they can handle the complexity of your project within the required timelines.

4. Quality Assurance: Investigate quality control measures the fabricator has in place. Confirm their adherence to welding standards and material certifications to avoid potential issues with structural integrity.

5. Cost Considerations: While price is important, it shouldn’t be the sole deciding factor. Balance cost with quality and reliability. Request detailed quotes to understand what is included and avoid hidden costs.

6. Communication and Collaboration: Choose a fabricator that demonstrates strong communication skills and is willing to collaborate during the design process. Effective communication can facilitate problem-solving and lead to better project outcomes.

7. Delivery and Timelines: Discuss delivery schedules upfront. Timely delivery is crucial to maintain your project’s timeline, so ensure the fabricator can meet your deadlines.

By considering these factors, you can enhance your procurement process and ensure a successful partnership with your steelwork fabrication provider.

FAQs on Sourcing and Manufacturing from steelwork fabrication in China

FAQs on Sourcing and Manufacturing Steelwork Fabrication in China

1. Why source steelwork fabrication from China?

China is a global leader in steel production, offering competitive pricing, advanced manufacturing technology, and vast supply capacity. The country’s established supply chains and skilled workforce enhance the efficiency and quality of steelwork fabrication.

2. What types of steelwork can be fabricated?

Common types include structural steel beams, columns, frames, and custom metal fabrications for construction, automotive, and shipbuilding industries.

3. How do I find reliable manufacturers?

Research potential suppliers through platforms like Alibaba, Made-in-China, and Global Sources. Additionally, check reviews, request references, and consider third-party verification services.

4. What is the typical lead time for fabrication?

Lead times vary depending on the complexity of the project, material availability, and order size. Generally, 4-12 weeks is standard, but confirm with your manufacturer.

5. Can I customize my design?

Yes, most manufacturers can accommodate custom designs using CAD files. Be clear about specifications and provide detailed drawings.

6. What are the quality control measures?

Reputable manufacturers implement quality control at various stages, including material inspection, in-process checks, and final inspections. Ask for certifications like ISO 9001.

7. How is shipping handled?

Discuss shipping terms with your manufacturer. Options include air freight for speed or sea freight for cost-effectiveness. Ensure to factor in customs duties and regulations.

8. What payments methods are safe?

Secure payment methods include letters of credit, PayPal, and escrow services. Avoid paying the full amount upfront; negotiate a payment plan.

9. What if there are issues with the order?

Establish clear communication channels. A reliable supplier will address issues promptly. Ensure to include a quality guarantee in your contract.