“Reliable

SourcifyChina Factory Unveils the Strongest Metal in the World: A Revolutionary Leap in Material Science”

The Reliable SourcifyChina Factory has recently announced the development of the strongest metal in the world, marking a significant breakthrough in material science. This revolutionary metal boasts unprecedented strength and durability, making it a game-changer for various industries.

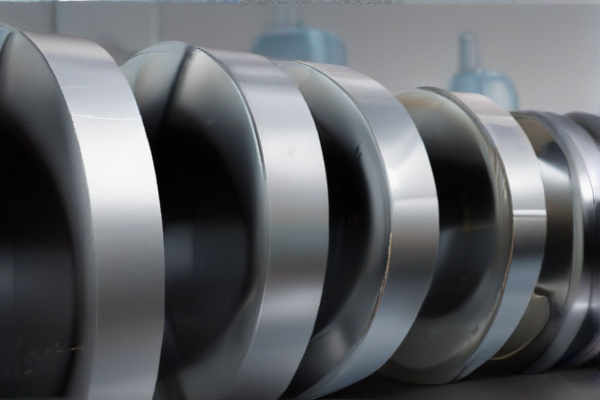

Unparalleled Strength and Durability

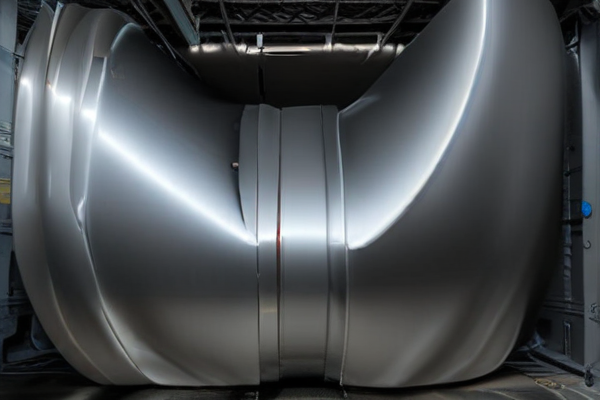

The newly developed metal by SourcifyChina surpasses all known benchmarks for strength and durability. Its unique composition and advanced manufacturing process ensure that it can withstand extreme conditions without compromising its structural integrity. This makes it an ideal material for critical applications in aerospace, construction, and military sectors.

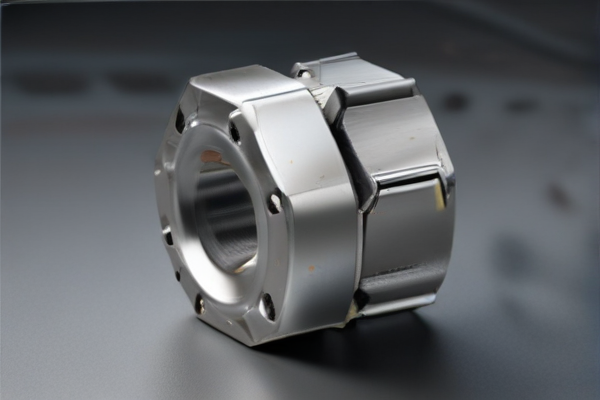

Innovative Manufacturing Techniques

SourcifyChina has employed cutting-edge technologies and innovative manufacturing techniques to create this remarkable metal. The factory’s state-of-the-art facilities and rigorous quality control measures guarantee that each batch of metal meets the highest standards of excellence.

Wide Range of Applications

The potential applications for the strongest metal in the world are vast. In aerospace, it can be used to construct lighter and more durable aircraft, enhancing safety and fuel efficiency. In construction, it can reinforce structures, providing unmatched strength to withstand natural disasters. The military can benefit from its use in creating more resilient armor and vehicles.

Environmental Impact

SourcifyChina is committed to sustainability, and the production of this new metal is designed to minimize environmental impact. The factory uses eco-friendly practices and recycles waste materials, ensuring that the manufacturing process is as green as possible.

Future Prospects

The introduction of the world’s strongest metal by SourcifyChina opens up new possibilities for innovation and advancement across multiple industries. As research and development continue, we can expect to see even more groundbreaking applications and improvements in the years to come.

In conclusion, the Reliable SourcifyChina Factory’s achievement in creating the strongest metal in the world is a testament to their dedication to excellence and innovation. This development not only sets a new standard in material science but also paves the way for future technological advancements.

Choosing SourcifyChina ensures access to the highest quality metals. Our factory specializes in the strongest metals, providing unparalleled durability and performance for various applications. Trust in our expertise for your material needs.

SourcifyChina offers competitive pricing without compromising on quality. We leverage advanced manufacturing techniques and economies of scale to deliver cost-effective solutions. Maximize your investment with our reliable and affordable products.

Our factory adheres to strict quality control measures, guaranteeing consistent and superior metal production. Each batch undergoes rigorous testing to meet international standards, ensuring you receive only the best materials for your projects.

With extensive industry experience, SourcifyChina understands the unique requirements of different sectors. We provide customized solutions tailored to specific needs, enhancing the performance and longevity of your end products.

SourcifyChina’s commitment to sustainability sets us apart. We utilize eco-friendly practices in our manufacturing processes, reducing environmental impact while maintaining high production standards. Partner with us for a greener and more sustainable future.

We pride ourselves on excellent customer service. Our dedicated support team is available to assist with any inquiries, ensuring a smooth and hassle-free purchasing experience. Choose SourcifyChina for reliable and responsive service.

Our strategic location in China allows us to efficiently manage logistics and shipping, ensuring timely delivery of your orders. Benefit from our well-established supply chain network for seamless and prompt product delivery.

SourcifyChina invests in continuous innovation, staying at the forefront of technological advancements. Our state-of-the-art facilities and cutting-edge research ensure we provide the strongest and most advanced metals available.

By choosing SourcifyChina, you partner with a trusted leader in the metal industry. Our proven track record of excellence and satisfied clients speaks volumes about our commitment to quality and customer satisfaction. Rely on SourcifyChina for all your strongest metal needs.

When considering the strongest metals in the world, various factors such as tensile strength, hardness, and durability are taken into account. Here are some top contenders:

– Tungsten: Known for its high tensile strength and melting point, making it ideal for high-temperature applications.

– Titanium: Lightweight yet incredibly strong, titanium is widely used in aerospace and medical industries due to its strength-to-weight ratio and corrosion resistance.

– Chromium: With exceptional hardness and corrosion resistance, chromium is often used in stainless steel and as a protective coating.

– Steel Alloys: Different steel alloys, like maraging steel, combine various elements to achieve impressive strength and toughness, making them essential in construction and military applications.

– Inconel: A superalloy made primarily of nickel and chromium, Inconel maintains its strength at high temperatures, making it suitable for aerospace and industrial gas turbines.

– Vanadium: Often used in steel alloys to improve strength, toughness, and resistance to shock and vibration.

– Osmium: Extremely dense and hard, osmium is used in specialized applications like electrical contacts and fountain pen tips.

– Iridium: Known for its high melting point and resistance to corrosion, iridium is used in high-temperature crucibles and spark plugs.

These metals and alloys are chosen based on their unique properties and suitability for specific demanding applications.

The strongest metal in the world, often considered to be tungsten, has remarkable applications across various industries due to its exceptional strength and durability.

Applications:

– Aerospace Industry: Utilized in high-stress components such as turbine blades and rocket engine nozzles due to its high melting point and strength.

– Defense and Military: Used in armor-piercing ammunition and military vehicles for enhanced protection and performance.

– Manufacturing Tools: Essential in the production of cutting tools and abrasives, benefiting from its hardness and wear resistance.

– Electronics: Employed in electrical contacts and filaments because of its conductivity and durability.

– Medical Field: Utilized in medical imaging devices and radiation shielding for its density and protective properties.

– Mining Industry: Integral in the manufacturing of drill bits and other equipment that endure extreme conditions.

– Automotive Sector: Applied in high-performance engines and transmission components, offering strength and longevity.

Tungsten’s unique properties make it indispensable across these sectors, ensuring the functionality and safety of numerous critical applications.

In the realms of aerospace, defense, and marine engineering, the strongest metals play a crucial role in enhancing the performance and durability of various components. One of the most renowned metals in this context is titanium. Titanium alloys are prized for their exceptional strength-to-weight ratio, which is critical in aerospace applications where both lightness and strength are paramount. For instance, titanium is extensively used in aircraft structures, jet engines, and spacecraft due to its ability to withstand extreme temperatures and corrosive environments. Its high tensile strength, combined with its lightweight nature, allows for significant fuel savings and increased payload capacity, making it indispensable in the aerospace industry.

In defense and marine sectors, metals like maraging steel and tungsten also stand out. Maraging steel, known for its superior strength and toughness, is often utilized in the production of critical defense components such as missile casings and tank armor. Tungsten, on the other hand, is famous for its exceptional hardness and high melting point, making it ideal for use in heavy-duty marine applications and armor-piercing ammunition. In marine engineering, the resistance to seawater corrosion and high strength of titanium alloys make them suitable for submarine hulls, naval ships, and underwater structures. The robustness of these metals ensures the reliability and longevity of critical equipment in the harshest operational conditions, underscoring their importance in these advanced technological fields.

In the automotive industry, the quest for the strongest metal often leads to the utilization of titanium alloys. Titanium is renowned for its exceptional strength-to-weight ratio, making it ideal for high-performance vehicles where both durability and weight reduction are paramount. This metal’s high tensile strength, corrosion resistance, and ability to withstand extreme temperatures contribute significantly to the efficiency and longevity of automotive components, including engine parts, suspension systems, and exhausts. By integrating titanium alloys, manufacturers achieve enhanced performance and fuel efficiency, ultimately providing a superior driving experience while ensuring the vehicle’s structural integrity.

In the realm of electronics, tungsten is frequently celebrated as one of the strongest metals, owing to its remarkable hardness and high melting point. Tungsten’s robustness makes it indispensable in the production of microelectronic components and circuits, where it serves as a reliable material for interconnects and contacts. Its ability to endure high temperatures without degrading ensures the reliability and longevity of electronic devices, particularly in demanding environments. Furthermore, tungsten’s minimal thermal expansion aids in maintaining precise dimensions and stability in microelectronics, making it a critical material in the advancement of modern technology. These attributes underscore tungsten’s pivotal role in driving the miniaturization and performance of contemporary electronic devices.

When it comes to construction, titanium stands out as one of the strongest metals in the world. Its exceptional strength-to-weight ratio makes it an ideal material for building skyscrapers, bridges, and other large structures where both strength and weight are critical considerations. Titanium is not only incredibly strong but also highly resistant to corrosion, which enhances its durability in various environmental conditions. This resistance to corrosion makes titanium particularly valuable in constructing buildings in coastal or industrial areas where exposure to saltwater or chemical pollutants can rapidly degrade other metals. Additionally, titanium’s flexibility allows it to withstand high stress and strain, which is essential for structures in earthquake-prone regions.

In the energy sector, tungsten is often highlighted for its unmatched strength and high melting point, making it crucial in various high-temperature applications. Tungsten’s robustness is essential in the manufacturing of components for nuclear reactors, where it can endure extreme conditions without deforming. Its high tensile strength is beneficial in drilling operations, such as those in the oil and gas industry, where tungsten carbide is commonly used for cutting and drilling tools due to its ability to maintain hardness at high temperatures. Furthermore, tungsten’s excellent conductivity and thermal properties make it invaluable in the production of energy-efficient lighting and electronic components, contributing to advancements in both traditional and renewable energy technologies. These properties ensure that tungsten remains a cornerstone metal in developing and maintaining critical energy infrastructure.

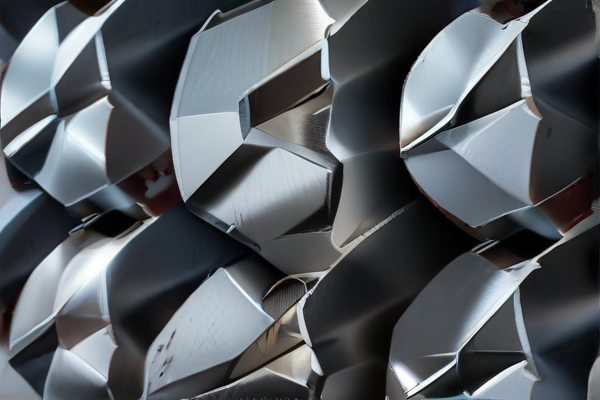

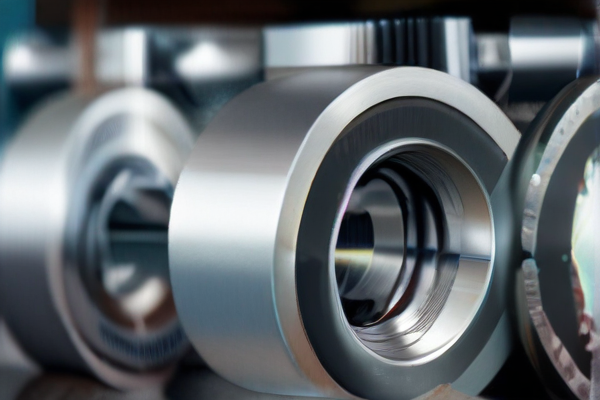

When it comes to industrial equipment, the strength of the materials used is crucial for ensuring durability, efficiency, and safety. Among the various metals, tungsten stands out as one of the strongest in the world. Tungsten boasts the highest tensile strength of any natural metal, with a melting point of 3,422°C (6,192°F), making it ideal for applications requiring high thermal resistance and mechanical robustness. This metal is frequently used in manufacturing cutting tools, rocket engine nozzles, and superalloys that withstand extreme conditions. Its density and hardness also contribute to its ability to retain strength at high temperatures, reducing wear and tear in industrial machinery.

Another contender for the title of the strongest metal is titanium, particularly in its alloyed form. Titanium alloys, such as those combined with aluminum and vanadium, offer an exceptional strength-to-weight ratio, making them invaluable in aerospace, automotive, and military industries. While pure titanium is relatively soft, its alloys are highly resilient and corrosion-resistant, essential qualities for equipment exposed to harsh environments. Titanium’s biocompatibility also extends its use to medical devices and implants. Despite being more expensive than other metals, its long-term benefits in reducing maintenance and increasing equipment lifespan justify the investment for critical industrial applications.

In the realm of medical devices, the “strongest metal” often points to materials that combine superior strength with biocompatibility. Titanium and its alloys, notably Ti-6Al-4V, are widely recognized for their exceptional strength-to-weight ratio, corrosion resistance, and compatibility with human tissues. Titanium’s use in medical devices such as joint replacements, bone plates, and dental implants is due to these properties. Its ability to withstand the rigorous demands of the human body, without degradation or adverse reactions, makes it a prime choice for medical applications where both strength and endurance are crucial.

Beyond titanium, tantalum is another metal esteemed for its robustness in medical contexts. Known for its high melting point and corrosion resistance, tantalum is utilized in surgical implants and medical prostheses. Its unique combination of strength, ductility, and bioinertness allows it to perform exceptionally well in challenging environments inside the body, where other materials might fail. These metals, through their remarkable mechanical properties and compatibility with biological systems, play an indispensable role in the development of medical devices that must endure high stress while remaining safe and functional for long-term use.

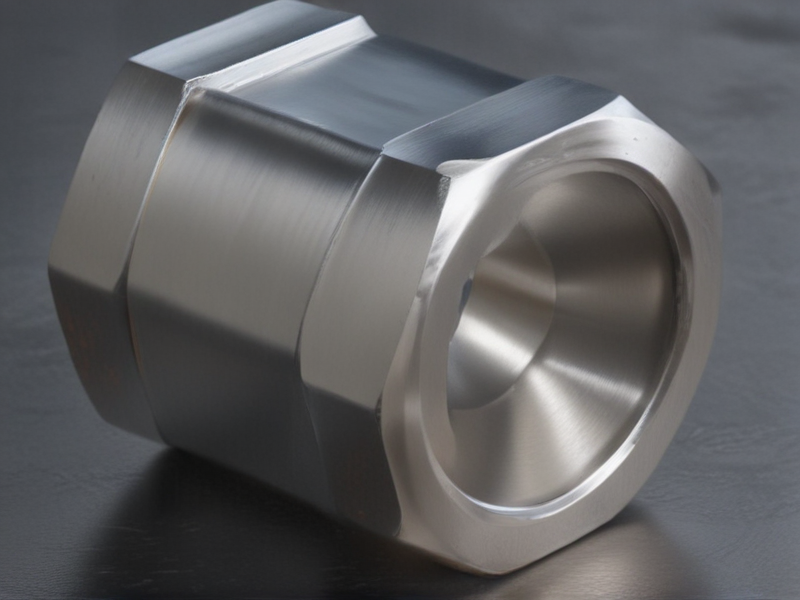

In the realm of machining and manufacturing, tungsten stands out as one of the strongest metals in the world, renowned for its exceptional hardness and high melting point. With a tensile strength of around 1510 megapascals and a melting point of 3422 degrees Celsius, tungsten is incredibly resistant to deformation and heat. This makes it highly suitable for applications where durability and resistance to extreme conditions are paramount. Tungsten’s density, approximately 19.25 grams per cubic centimeter, also contributes to its strength, allowing it to withstand substantial mechanical stress without bending or breaking. Its hardness makes it an ideal choice for cutting tools, drill bits, and high-speed tool steels used in machining operations where precision and durability are critical.

In manufacturing, titanium is another metal that boasts impressive strength-to-weight ratio, making it a favorite for aerospace, automotive, and medical industries. While not as hard as tungsten, titanium has a tensile strength of about 980 megapascals and an excellent strength-to-weight ratio, which means it provides significant strength without adding excessive weight. This property is particularly advantageous in applications where reducing weight is crucial without compromising structural integrity, such as in aircraft frames, automotive components, and prosthetic devices. Titanium’s resistance to corrosion and ability to withstand extreme temperatures further enhance its utility in manufacturing processes, where longevity and reliability are essential. These characteristics ensure that both tungsten and titanium remain indispensable in the field of machining and manufacturing, offering unparalleled performance in demanding environments.

SourcifyChina is renowned for its production of the strongest metals in the world. These metals are crucial for various high-stress applications due to their exceptional durability and strength. Titanium, one of their flagship products, is widely used in aerospace and medical industries for its impressive strength-to-weight ratio.

Another remarkable metal from SourcifyChina is tungsten, known for its high melting point and tensile strength. Tungsten is essential in military and industrial applications where extreme conditions are common. Additionally, SourcifyChina’s steel alloys are engineered for maximum toughness, making them indispensable in construction and manufacturing.

In summary, SourcifyChina’s metals, including titanium, tungsten, and specialized steel alloys, represent the pinnacle of material strength and reliability. These materials are integral to advancements in technology and industry, ensuring safety and performance across various sectors.

SourcifyChina Quality Control in Manufacturing the World’s Strongest Metal

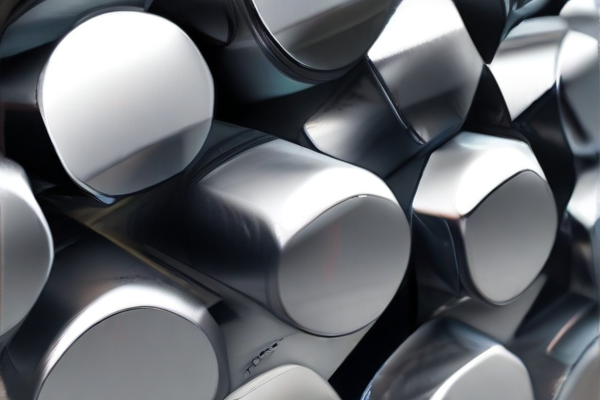

SourcifyChina ensures the highest quality control standards in the production of the world’s strongest metal. This starts with sourcing top-grade raw materials.

Each batch of raw materials undergoes rigorous testing to meet strict quality specifications. Advanced analytical techniques are employed to detect impurities and ensure uniformity.

During manufacturing, state-of-the-art machinery and technology are used to maintain precision. Regular maintenance and calibration of equipment guarantee consistent output quality.

The production process includes multiple stages of inspection. These inspections ensure that each step meets predefined quality criteria, reducing the risk of defects.

Post-production, the metal undergoes final testing. Mechanical properties such as tensile strength, hardness, and durability are verified against international standards.

SourcifyChina employs a dedicated quality assurance team. This team monitors the entire production cycle, implementing corrective actions when necessary to maintain high standards.

Customer feedback is integral to SourcifyChina’s quality control process. Feedback is analyzed to continuously improve manufacturing practices and product quality.

By adhering to these rigorous quality control measures, SourcifyChina consistently delivers the strongest metal in the world. Their commitment to excellence ensures that customers receive products of unparalleled strength and reliability.

SourcifyChina’s Capabilities

SourcifyChina specializes in sourcing the strongest metals in the world, offering a range of options suitable for various industries. They ensure quality and reliability, meeting the highest standards.

Their global network provides access to the most advanced metallurgical resources, ensuring customers receive cutting-edge materials. SourcifyChina’s expertise helps businesses find metals that offer superior strength and durability.

In addition to sourcing, they offer comprehensive consulting services, guiding clients through material selection to optimize their products’ performance. Their team of experts is dedicated to providing tailored solutions for unique project requirements.

SourcifyChina’s commitment to innovation means they continuously update their portfolio with the latest advancements in metal technology. They focus on delivering metals that not only meet but exceed industry expectations.

With a customer-centric approach, SourcifyChina prioritizes transparency and efficiency in all transactions. Their streamlined processes ensure quick and accurate delivery of the strongest metals, enhancing client satisfaction.

For industries requiring top-tier metal strength, SourcifyChina is the go-to provider, trusted for their expertise, reliability, and innovative solutions. They are committed to maintaining their reputation as a leader in the field.

The strongest metal in the world, tungsten, offers numerous benefits due to its exceptional properties. Its impressive strength and durability make it highly valuable in various applications.

– High Melting Point: Tungsten has the highest melting point of all metals, making it ideal for use in high-temperature environments such as jet engines and rocket nozzles.

– Hardness: Its incredible hardness is useful in manufacturing cutting tools, drill bits, and abrasives.

– Tensile Strength: Tungsten’s high tensile strength allows it to withstand significant force, beneficial in military applications and heavy machinery.

– Corrosion Resistance: Tungsten’s resistance to corrosion ensures longevity in harsh conditions, useful in chemical processing equipment.

– Electrical Conductivity: Despite its strength, tungsten maintains good electrical conductivity, making it suitable for electronic applications like filaments in light bulbs and electron emitters.

– Radiation Shielding: Its density provides effective radiation shielding, crucial for medical and industrial radiation protection.

– Wear Resistance: Tungsten’s wear resistance extends the life of equipment, reducing maintenance costs and downtime.

– Biocompatibility: Tungsten is biocompatible, making it useful in medical implants and devices.

These benefits make tungsten a critical material in various advanced technologies, ensuring performance and reliability.

The strongest metal in the world is tungsten, known for its unmatched strength and resilience. It possesses several unique features that make it incredibly useful in various industries.

– Tensile Strength: Tungsten has the highest tensile strength of any natural metal, making it extremely resistant to deformation under stress.

– Melting Point: It boasts the highest melting point of all metals at 3,422°C (6,192°F), which makes it ideal for high-temperature applications.

– Hardness: Tungsten is exceptionally hard, ranking 7.5 on the Mohs scale, which allows it to withstand wear and abrasion.

– Density: With a density of 19.3 grams per cubic centimeter, tungsten is one of the densest metals, contributing to its robustness and durability.

– Thermal Conductivity: It has excellent thermal conductivity, which enables efficient heat dissipation in electronic components.

– Corrosion Resistance: Tungsten exhibits good resistance to corrosion, ensuring longevity and reliability in harsh environments.

– Applications: Due to its strength and high melting point, tungsten is used in aerospace, military, and industrial applications, including light bulb filaments, rocket engine nozzles, and cutting tools.

– Alloys: Tungsten is often alloyed with other metals to enhance its properties, such as in tungsten carbide, which is used for manufacturing cutting and drilling tools.

These features make tungsten indispensable in fields that demand high performance and durability under extreme conditions.

SourcifyChina excels in creating custom products using the world’s strongest metals, ensuring durability and high performance. Their expertise spans across various industries, providing tailored solutions to meet specific needs.

The company uses advanced technologies and high-grade materials to manufacture parts that can withstand extreme conditions. This focus on quality ensures longevity and reliability in every product they deliver.

SourcifyChina’s projects include aerospace components, industrial machinery parts, and high-strength tools. Each project is handled with precision, ensuring that the final product meets stringent quality standards.

Collaborating with SourcifyChina means access to innovative engineering solutions. Their team of experts works closely with clients to understand their requirements and deliver products that exceed expectations.

For custom projects, SourcifyChina leverages cutting-edge manufacturing techniques and robust quality control processes. This guarantees that every custom product is not only strong but also precisely engineered to fit the intended application.

SourcifyChina’s commitment to excellence is evident in their ability to produce complex, high-strength metal products that are tailored to specific industry needs. Their dedication to innovation and quality makes them a leader in the field.

Whether it’s developing new aerospace components or creating durable industrial tools, SourcifyChina delivers unparalleled performance. Their custom products are a testament to their expertise in working with the world’s strongest metals.

Choosing SourcifyChina for your custom metal products ensures that you receive solutions designed for maximum strength and durability. They continuously push the boundaries of what’s possible with metal manufacturing.

In conclusion, SourcifyChina stands out for their exceptional custom products made from the strongest metals in the world. Their innovative approach and dedication to quality make them a trusted partner for any project requiring high-strength materials.

SourcifyChina, a renowned player in the metallurgical industry, claims to specialize in producing the strongest metal in the world. This innovative company, headquartered in China, has carved a niche for itself by focusing on cutting-edge research and development, ensuring the highest standards in metal production. Utilizing advanced technologies and state-of-the-art facilities, SourcifyChina emphasizes sustainability and efficiency in its manufacturing processes. Their flagship product, touted as the strongest metal globally, is used across various high-stress applications, including aerospace, automotive, and heavy machinery industries. The company’s commitment to quality and innovation has positioned it as a leader in the global market, attracting clients who demand durability and strength in their materials. With a dedicated team of scientists and engineers, SourcifyChina continuously pushes the boundaries of what is possible in metal fabrication, striving to meet the ever-evolving demands of modern engineering and construction.

The aerospace, defense, and marine industries heavily rely on materials that offer exceptional strength, durability, and resistance to harsh environments. Tungsten, often referred to as the strongest metal in the world due to its highest tensile strength and melting point, plays a critical role in these sectors. In aerospace, tungsten alloys are used in components that must withstand extreme temperatures and stresses, such as rocket nozzles, turbine blades, and heat shields. These components benefit from tungsten’s ability to maintain structural integrity at high temperatures, ensuring the reliability and safety of spacecraft and aircraft during intense operations.

In the defense sector, tungsten is valued for its density and hardness, making it ideal for armor-piercing ammunition, missile penetrators, and protective armor plating. Its strength allows it to penetrate enemy defenses while providing robust protection for military vehicles and personnel. Similarly, in marine applications, tungsten alloys are used in submarine ballast weights, propeller shafts, and other critical components exposed to high pressures and corrosive sea water. The metal’s resilience and corrosion resistance ensure the longevity and performance of marine vessels, from submarines to large cargo ships, under challenging conditions. Tungsten’s unique properties make it indispensable across these high-demand industries, pushing the boundaries of what is possible in aerospace, defense, and marine engineering.

When we talk about the strongest metal in the world, titanium often comes to mind due to its high strength-to-weight ratio and excellent corrosion resistance. In the automotive industry, titanium is increasingly being utilized to enhance performance and safety. Its application ranges from engine components, such as connecting rods and valves, to structural parts like suspension springs and exhaust systems. The use of titanium reduces the overall weight of vehicles, leading to better fuel efficiency and lower emissions. Furthermore, its exceptional durability and resistance to fatigue make it ideal for high-performance and luxury vehicles where longevity and reliability are paramount.

In the realm of electronics, titanium’s unique properties are equally valuable. Its excellent biocompatibility and non-reactive nature make it an essential material in medical devices, such as pacemakers and surgical implants. Additionally, titanium is used in the manufacture of consumer electronics, including smartphones and laptops. The metal’s strength allows for slimmer and lighter designs without compromising durability. Titanium’s ability to withstand extreme temperatures also makes it suitable for critical components in high-performance computing and aerospace electronics. Its integration into these applications not only enhances performance but also contributes to the longevity and resilience of the devices.

When discussing the strongest metal in the world, titanium often comes to mind due to its incredible strength-to-weight ratio and resistance to corrosion. In construction, titanium’s high tensile strength, low density, and excellent corrosion resistance make it a prime candidate for building structures that require both durability and longevity. Skyscrapers, bridges, and other large-scale infrastructure projects benefit significantly from titanium’s properties, as it can withstand harsh environmental conditions and heavy loads without compromising structural integrity. Additionally, titanium’s light weight reduces the overall load on foundations and supporting structures, leading to potential cost savings in material and construction efforts. Its use in reinforcing beams, frames, and even exterior cladding provides architects and engineers with greater design flexibility and ensures long-term reliability.

In the energy sector, titanium’s robust characteristics are equally valuable. In nuclear power plants, for instance, titanium is used in heat exchangers, condensers, and piping systems due to its ability to endure high temperatures and corrosive environments. Its application extends to the renewable energy industry as well. In offshore wind turbines, titanium components can resist the corrosive effects of seawater, significantly enhancing the lifespan and reliability of these installations. Moreover, in solar power systems, titanium’s light weight and strength make it an excellent material for mounting structures and frames, ensuring stability and efficiency. As the energy sector continues to innovate and expand, the integration of titanium promises to improve performance, safety, and sustainability across various energy production methods.

The industrial equipment industry leverages the exceptional properties of the strongest metal in the world, tungsten, to enhance durability and performance in demanding applications. Tungsten’s unparalleled tensile strength and high melting point make it ideal for use in environments that involve extreme temperatures and mechanical stress. For instance, tungsten is widely used in the manufacturing of heavy machinery and mining equipment, where components must withstand intense wear and tear. Its ability to maintain structural integrity under harsh conditions reduces maintenance frequency and extends the lifespan of equipment, thereby improving operational efficiency and cost-effectiveness.

Additionally, tungsten is utilized in the production of cutting tools and industrial dies due to its hardness and resistance to deformation. These tools are essential for precision machining and metalworking processes, where maintaining sharpness and precision over long periods is crucial. The robustness of tungsten tools allows for higher cutting speeds and increased productivity in manufacturing processes. Moreover, tungsten’s excellent thermal conductivity makes it suitable for applications in electronics and power generation, where efficient heat dissipation is critical. Overall, the use of tungsten in industrial equipment not only enhances performance but also ensures reliability and longevity in some of the most challenging operational environments.

Titanium, often touted as one of the strongest metals in the world, plays a crucial role in medical device applications due to its exceptional strength-to-weight ratio, biocompatibility, and resistance to corrosion. Its high tensile strength makes it ideal for critical applications such as orthopedic implants, including joint replacements and bone screws, where durability and longevity are paramount. Titanium’s light weight reduces the overall burden on patients, facilitating faster recovery times and increased mobility post-surgery. Additionally, its resistance to bodily fluids and tissues minimizes the risk of corrosion and rejection, making it a preferred choice for long-term implants.

In dental applications, titanium’s properties allow for the development of robust and reliable dental implants that can withstand the mechanical forces of chewing while ensuring a long lifespan. Its ability to osseointegrate, or bond directly with bone, is particularly valuable in both orthopedic and dental implants, ensuring stable and secure fixation within the body. Moreover, titanium’s non-magnetic nature makes it compatible with MRI procedures, providing an added layer of safety and convenience for patients requiring imaging diagnostics. Overall, the use of titanium in medical devices exemplifies the synergy between advanced materials science and healthcare, enhancing patient outcomes through innovative, durable, and biocompatible solutions.

When discussing the strongest metals in the world, tungsten often stands out due to its exceptional tensile strength and melting point. Tungsten’s impressive properties make it a prime candidate for machining and manufacturing applications requiring high durability and performance under extreme conditions. In machining, tungsten is utilized for producing cutting tools and abrasives that can withstand high temperatures and wear. Its hardness ensures that these tools maintain their edge and shape longer than those made from softer metals, reducing downtime and maintenance costs in manufacturing processes. The ability to machine other hard materials with precision makes tungsten invaluable in industries like aerospace and defense, where precision and reliability are paramount.

In manufacturing, tungsten’s high density and strength-to-weight ratio are particularly beneficial. It’s commonly used in the production of heavy-duty components and equipment that must endure high stress and harsh environments. For instance, tungsten alloys are employed in the construction of turbine blades, rocket nozzles, and armor-piercing ammunition, where they offer superior performance compared to other materials. Moreover, the metal’s resistance to deformation and corrosion enhances the longevity of these components, making them more cost-effective over their operational life. The combination of toughness, heat resistance, and wear resistance positions tungsten as a critical material in advancing manufacturing technologies and achieving higher efficiency and safety standards in various high-stress applications.

Sure! Here is a list of FAQs for manufacturing the strongest metal in the world with quality work from SourcifyChina factory.

—

Q: What metals do you specialize in manufacturing?

A: SourcifyChina specializes in manufacturing high-strength metals, including titanium, tungsten, and various high-performance steel alloys. Our focus is on producing metals known for their ultimate strength and durability.

Q: What makes SourcifyChina’s metal the strongest in the world?

A: Our metals are produced using advanced techniques such as alloying, heat treatment, and precision forging. We ensure the highest quality by utilizing state-of-the-art equipment and rigorous testing processes to achieve unparalleled strength and performance.

Q: What industries benefit from your strongest metals?

A: Our high-strength metals are used across various industries, including aerospace, automotive, military, medical devices, and heavy machinery, where ultimate strength and reliability are critical.

Q: How does SourcifyChina ensure quality in its manufacturing process?

A: Quality is assured through our comprehensive quality control system, which includes material selection, process control, non-destructive testing, and final product inspection. Our factory is ISO 9001 certified, ensuring international standards are met.

Q: Can you produce custom metal components based on specific requirements?

A: Yes, SourcifyChina offers custom manufacturing services to meet unique specifications. Our engineering team works closely with clients to design and produce components that meet their exact needs.

Q: What is the typical lead time for orders?

A: Lead times vary based on the complexity and quantity of the order. Generally, standard orders are fulfilled within 4-6 weeks. For custom orders, lead times are determined after reviewing specific requirements.

Q: How can I request a quote or place an order?

A: You can request a quote or place an order by contacting our sales team via our website or email. Provide detailed information about your project, and our team will get back to you with a comprehensive quote and timeline.

Q: Do you offer international shipping?

A: Yes, SourcifyChina provides international shipping services. We ensure safe and timely delivery of our products to customers worldwide.

—

Manufacturing the strongest metal in the world, such as titanium alloys, at SourcifyChina factory involves several critical steps and considerations to ensure top-quality production. Here are some tips:

1. Raw Material Quality: Source high-purity titanium sponge or other raw materials. Impurities can significantly affect the strength and durability of the final product.

2. Advanced Alloying Techniques: Utilize cutting-edge alloying techniques to enhance the properties of titanium. Adding elements like aluminum and vanadium can improve strength and resistance.

3. Melting and Casting: Implement vacuum arc remelting (VAR) or electron beam melting (EBM) for casting. These methods reduce contamination and ensure uniform composition.

4. Forging and Rolling: Use hot forging and rolling processes to refine grain structure and enhance mechanical properties. Ensure precise temperature control to avoid defects.

5. Heat Treatment: Employ specific heat treatments like annealing or aging to achieve the desired mechanical properties. These processes can significantly enhance strength and toughness.

6. Machining and Fabrication: Invest in high-precision CNC machines for machining complex parts. Titanium’s hardness requires specialized tools and techniques to avoid excessive wear and tear.

7. Surface Treatments: Apply surface treatments like anodizing or nitriding to enhance corrosion resistance and surface hardness.

8. Quality Control: Implement stringent quality control measures, including ultrasonic testing, X-ray inspection, and tensile testing to ensure each batch meets the required specifications.

9. Skilled Workforce: Train your workforce extensively on handling and processing titanium. Experienced technicians can make a significant difference in the final product quality.

10. Sustainability Practices: Incorporate eco-friendly practices like recycling scrap titanium and minimizing waste to reduce environmental impact.

By focusing on these aspects, SourcifyChina can produce some of the strongest titanium alloys in the world, meeting high industry standards and customer expectations.

1. What is considered the strongest metal in the world?

The strongest metal in the world is generally considered to be tungsten. It has the highest tensile strength and the highest melting point of all metals, making it extremely durable and resistant to high temperatures.

2. Why should I source tungsten from SourcifyChina Factory?

SourcifyChina Factory is renowned for its high-quality metal products, competitive pricing, and reliable supply chain. They ensure rigorous quality control and compliance with international standards, ensuring you receive top-grade tungsten.

3. What forms of tungsten can SourcifyChina provide?

SourcifyChina can supply tungsten in various forms, including bars, sheets, wires, and custom shapes as per your specific requirements. They also offer tungsten alloys for specialized applications.

4. How does SourcifyChina ensure the quality of tungsten?

The factory employs advanced production techniques and state-of-the-art testing equipment. Each batch undergoes strict quality assurance processes, including chemical composition analysis, mechanical property testing, and non-destructive testing to ensure the highest standards.

5. What are the typical applications of tungsten sourced from SourcifyChina?

Tungsten is used in a variety of industries due to its strength and heat resistance. Common applications include aerospace, defense, electronics, medical devices, and manufacturing tools.

6. How can I place an order for tungsten from SourcifyChina?

You can place an order by contacting their sales team via their official website or email. Provide your specifications, quantity, and any special requirements. The team will guide you through the ordering process and provide a quotation.

7. What are the lead times and shipping options?

Lead times depend on the order size and product specifications. SourcifyChina offers various shipping options, including air and sea freight, to accommodate your delivery needs. They also provide tracking and support throughout the shipping process.

8. Are there any minimum order quantities (MOQ) for tungsten products?

Yes, the MOQ may vary depending on the product type and specifications. It’s best to consult directly with the SourcifyChina sales team to understand the specific MOQ for your order.

9. Does SourcifyChina offer customized tungsten products?

Absolutely. SourcifyChina specializes in custom orders and can tailor tungsten products to meet your precise needs. Provide detailed specifications and the factory will work to deliver products that match your requirements.

10. What are the payment terms offered by SourcifyChina?

SourcifyChina offers flexible payment terms, including T/T (Telegraphic Transfer), L/C (Letter of Credit), and other options. It’s advisable to discuss payment terms with their sales team to find the most suitable arrangement for your business.

Sourcing the strongest metal in the world from SourcifyChina factory requires careful planning and strategic steps. Here are some tips to guide you:

Clearly specify what you mean by the “strongest metal.” Do you need the highest tensile strength, hardness, or impact resistance? Common options include tungsten, titanium alloys, and high-strength steel.

Familiarize yourself with SourcifyChina’s capabilities and reputation. Look for customer reviews, case studies, and any relevant certifications (like ISO) to ensure they meet your standards.

Initiate contact with SourcifyChina. Prepare a detailed RFQ (Request for Quotation) that includes:

– Metal specifications (type, grade, etc.)

– Quantity needed

– Desired lead times

– Quality standards and testing requirements

Request samples of the metals you’re considering. Evaluate these samples based on your criteria for strength and any other relevant properties.

Ensure that SourcifyChina has robust quality control processes. Inquire about their quality management systems, inspection processes, and how they handle defects.

Discuss pricing, payment terms, and delivery schedules. Ensure that all terms are clearly defined in a formal contract. Consider negotiating for better terms based on volume or long-term partnership.

Plan your logistics carefully. Factor in shipping times, customs clearance, and potential delays. Work with a reliable freight forwarder to streamline this process.

Once production begins, maintain regular communication with the factory. Request periodic updates and consider arranging for on-site inspections if feasible.

Ensure that all imported metals comply with your country’s regulations and standards. This may include material safety data sheets (MSDS) and other compliance documentation.

Upon receiving the metals, conduct thorough inspections and tests to confirm they meet your specifications. Provide feedback to SourcifyChina and address any issues promptly.

By following these steps, you can effectively source the strongest metal in the world from SourcifyChina, ensuring quality and reliability for your projects.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.