“Sourcify: Your Reliable China Factory for the Strongest Metals”

Discover why Sourcify is the go-to China factory for sourcing the strongest metals with unparalleled reliability and quality assurance. Perfect for industries demanding top-tier material integrity and performance.

“SourcifyChina” Factory has established itself as a reliable supplier of high-quality metals from China. With a focus on stringent quality control, the firm assures buyers of receiving premium and durable materials.

Their extensive network of vetted manufacturers allows for competitive pricing without compromising on standards. This ensures cost-effective solutions for any project size.

Moreover, “SourcifyChina” offers outstanding customer service, guiding buyers through each step of the purchasing process. From initial inquiries to final delivery, their team ensures seamless transactions and customer satisfaction.

Investing in strong metals from “SourcifyChina” means leveraging their expertise, reliability, and comprehensive support, making it the optimal choice for global buyers seeking quality and affordability.

When discussing the strongest metals, several stand out due to their exceptional strength, durability, and resistance to wear and corrosion. These metals are essential in various industrial and technological applications.

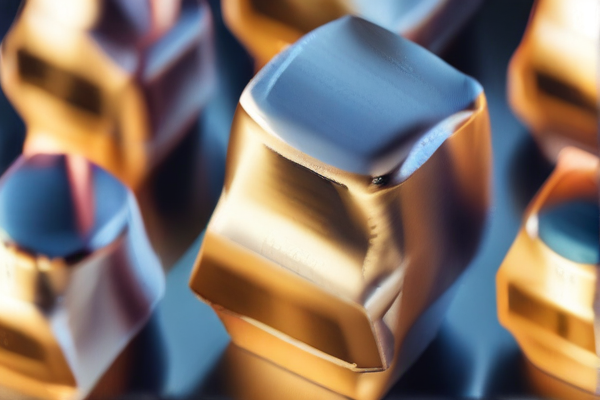

– Tungsten: Known for its high melting point and tensile strength.

– Titanium: Combines lightweight properties with high strength and corrosion resistance.

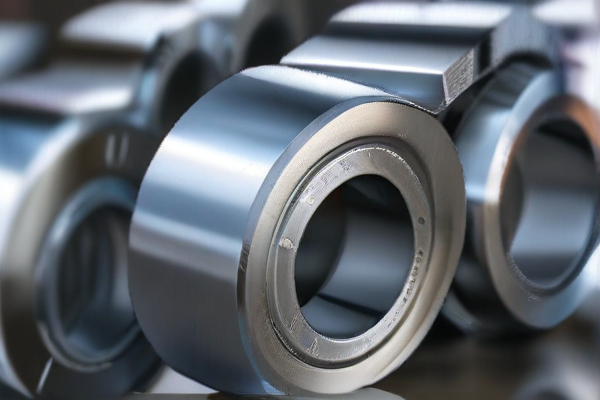

– Steel Alloys: Various compositions designed for specific strengths and uses, like carbon steel and stainless steel.

– Chromium: Essential in stainless steel, it provides excellent hardness and corrosion resistance.

– Inconel: This superalloy maintains strength and oxidation resistance at high temperatures.

– Vanadium: Adds strength and resistance to shock and corrosion when alloyed.

– Tantalum: Highly resistant to corrosion and used in electronics and medical devices.

– Osmium: One of the densest elements, with significant hardness and wear resistance.

Each of these metals offers unique properties that make them ideal for different high-strength applications, from aerospace engineering to construction and medical devices.

Strongest metals, such as titanium and tungsten, are highly valued for their exceptional strength and durability. These metals are crucial in various industries due to their ability to withstand extreme conditions.

– Aerospace: Used in aircraft frames, engines, and spacecraft to endure high stresses and temperatures.

– Medical Field: Titanium is used for surgical instruments, implants, and prosthetics due to its biocompatibility.

– Military: Armor plating for vehicles, bunkers, and protective gear benefits from the strength and resilience of these metals.

– Construction: Tungsten and steel alloys are utilized in building beams and reinforcements for skyscrapers and bridges.

– Automotive: Strong metals improve vehicle durability and performance in critical components like engines and suspensions.

– Sporting Goods: High-strength metals enhance the performance and longevity of equipment such as golf clubs, bicycles, and climbing gear.

– Electronics: Used in high-performance electronic components for improved durability and heat resistance.

– Industrial Equipment: Machinery and tools operating under heavy use and high pressure require metals with superior strength.

– Marine Engineering: Shipbuilding and underwater pipelines rely on metal components that can withstand corrosive environments and high pressure.

– Energy Sector: Wind turbines, nuclear reactors, and oil drilling equipment require materials that maintain structural integrity under extreme conditions.

Strongest metals play a vital role in advancing technology and improving the safety and performance of various applications, demonstrating their indispensable nature across multiple fields.

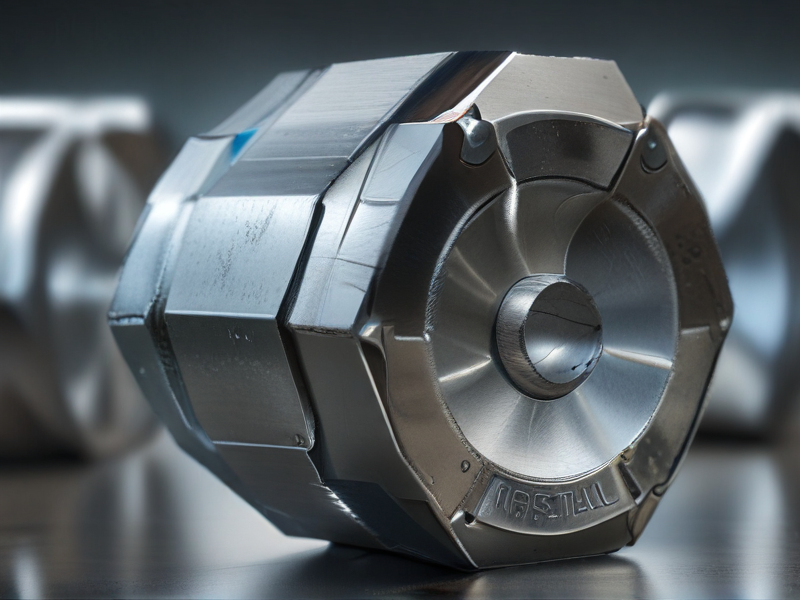

SourcifyChina specializes in sourcing some of the world’s strongest metals. These materials include titanium, stainless steel, and tungsten. Each metal is known for its exceptional durability and versatility in various industries.

Titanium is prized for its high strength-to-weight ratio and excellent corrosion resistance. It is commonly used in aerospace, medical devices, and high-performance engineering applications. Its extraordinary resilience makes it invaluable for critical components.

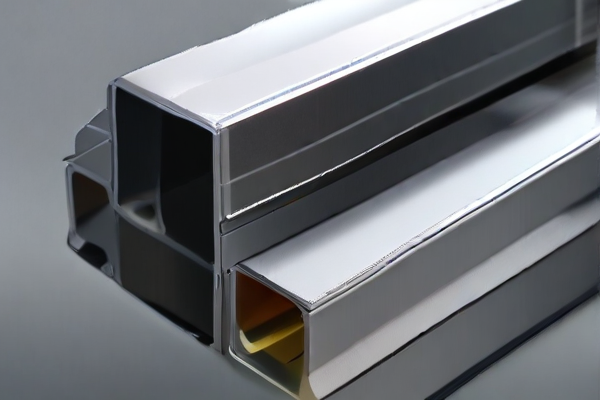

Stainless steel, an alloy containing iron, chromium, and nickel, offers robust resistance to rust and staining. Its aesthetic appeal and durability make it ideal for kitchenware, construction, and automotive parts. It’s a reliable option for both functional and decorative uses.

Tungsten is renowned for its high melting point and substantial hardness. It’s frequently utilized in electrical applications, such as filaments in light bulbs, and industrial machinery tools. Tungsten’s rigidity and endurance are perfect for demanding environments.

SourcifyChina provides these metals with high precision and quality control, ensuring they meet international standards. Whether for aeronautic projects, medical advancements, or industrial applications, these materials enable innovation and reliability. By focusing on these key metals, SourcifyChina supports diverse industries in achieving remarkable performance and durability in their products and solutions.

SourcifyChina employs a comprehensive quality control process to ensure the highest standards for its strongest metals. Each step, from raw material selection to final inspection, is meticulously monitored. Advanced techniques are used to guarantee purity and strength.

The manufacturing process begins with the careful selection of top-grade raw materials. These materials undergo rigorous testing to verify their composition and quality. Only those that meet stringent criteria proceed.

Advanced machinery and skilled technicians are employed during production to maintain precision and consistency. Regular inspections at various stages are conducted to detect and rectify any anomalies early.

Post-production, each batch of metal is subjected to a series of tests, including tensile strength, hardness, and corrosion resistance. State-of-the-art equipment ensures that all measurements are accurate and reliable.

The final inspection phase is crucial. Here, the metals are re-examined to meet specified standards. Any deviation results in a thorough review and necessary corrections to ensure compliance.

SourcifyChina’s quality control extends beyond manufacturing. All processes and changes are documented for traceability. This enables the company to ensure consistency and accountability in every production cycle.

Feedback loops are in place to continuously improve the quality control process. Regular training and updates on industry standards keep the team adept and informed. Continuous improvement is a core principle.

By adhering to strict quality control measures, SourcifyChina delivers robust and reliable metals. Ensuring every product adheres to the highest standards solidifies their reputation in the industry, providing customers with consistent, top-tier quality they can trust.

SourcifyChina specializes in the production of the strongest metals that meet international standards for durability and performance. Their advanced technologies enable high-quality metal fabrication suitable for various industrial applications.

The company excels in custom metal solutions, offering tailored production processes to meet specific customer requirements. SourcifyChina’s capabilities extend to precision machining, robust alloy creation, and intricate metalworks, ensuring comprehensive solutions.

Their state-of-the-art facilities house cutting-edge tools and a skilled workforce, enabling them to produce metals with enhanced tensile strength and resistance to wear and tear. Their quality control measures ensure each batch meets stringent standards.

Further, SourcifyChina’s expertise in metallurgy allows them to innovate consistently, introducing new metal compositions that outperform traditional materials. Their strong research and development team ensures they stay ahead of industry trends.

In addition to mechanical properties, the company emphasizes sustainability in their processes. Their eco-friendly practices minimize waste and energy consumption, aligning with global sustainability goals and customer expectations.

SourcifyChina’s customer-centric approach emphasizes strong communication and collaboration with clients, guaranteeing high satisfaction rates. Their comprehensive after-sales support ensures long-lasting partnerships and fosters trust among stakeholders.

Overall, SourcifyChina is committed to delivering top-tier, durable metal solutions for a wide range of sectors, including automotive, aerospace, construction, and manufacturing. This makes them a reliable partner for businesses seeking uncompromising quality and innovative metal products.

Strongest metals, like titanium, tungsten, and steel, offer numerous advantages due to their unparalleled strength, durability, and resistance to extreme conditions.

– Durability: These metals ensure longevity in applications such as construction, aerospace, and manufacturing, reducing the need for frequent replacements.

– Corrosion Resistance: Many strong metals resist rust and corrosion, making them ideal for use in harsh environments, like marine and chemical industries.

– High Strength-to-Weight Ratio: Metals like titanium provide exceptional strength without excessive weight, critical in industries such as aerospace and automotive, improving efficiency and fuel economy.

– Heat Resistance: Strong metals can withstand high temperatures, enhancing performance in applications like jet engines and power plants.

– Electrical Conductivity: Metals like copper provide excellent electrical conductivity, crucial for electrical engineering and electronics.

– Safety and Reliability: The superior mechanical properties of the strongest metals ensure the safety and reliability of critical infrastructure and machinery.

– Versatility: Due to their many favorable properties, these metals can be used in a wide range of applications, from medical implants to advanced weaponry.

By leveraging the benefits of the strongest metals, industries can achieve greater performance, safety, and sustainability, ultimately driving technological advancements and improving quality of life.

The strongest metals are defined by their ability to withstand various types of stress, including tensile, compressive, and shear forces.

– Tensile Strength: The resistance to being pulled apart. Metals like tungsten and titanium are known for high tensile strength.

– Compressive Strength: The ability to withstand loads that reduce size. Metals such as steel excel in compressive strength.

– Hardness: The resistance to deformation or indentation. Diamonds, though not a metal, combined with certain alloys like stainless steel, enhance hardness.

– Ductility: The capacity to be stretched into a wire without breaking. Gold and silver are highly ductile.

– Elasticity: The ability to return to its original shape after deformation. Springs often utilize metals with significant elasticity, like tempered steel.

– Corrosion Resistance: The ability to withstand damage from environmental elements. Stainless steel and titanium are notable for their high corrosion resistance.

– Thermal Conductivity: The rate at which a metal transfers heat. Metals like copper and aluminum are highly effective thermal conductors.

– Density: The mass per unit volume. Iridium and osmium are among the densest metals, contributing to their strength.

The properties and applications of these metals make them crucial in industries ranging from aerospace to medical devices, where both resilience and performance are non-negotiable.

SourcifyChina specializes in creating custom products and projects using the world’s strongest metals. Their expertise spans various industries, ensuring high-quality, durable solutions tailored to meet client specifications. This versatility enables comprehensive coverage from industrial machinery to intricate aerospace components.

The company prides itself on utilizing advanced manufacturing techniques and state-of-the-art technology. By combining innovation and precision engineering, SourcifyChina ensures that every product meets stringent international standards, delivering unmatched performance and reliability. Their commitment to excellence makes them a trusted partner for businesses seeking superior metal products.

SourcifyChina’s diverse portfolio includes high-strength alloys like titanium, tungsten, and steel. These materials are meticulously sourced and rigorously tested to guarantee optimal performance in demanding environments. Their robust properties make them ideal for applications requiring resilience and longevity, pushing the boundaries of what’s possible in modern engineering.

Sustainability is another key focus for SourcifyChina. The company employs eco-friendly processes and strives to minimize environmental impact throughout the production lifecycle. By promoting responsible practices and innovation, they contribute to a greener, sustainable future without compromising on quality or performance.

Customer satisfaction is at the heart of SourcifyChina’s mission. They offer personalized service, ensuring that every project aligns perfectly with client needs. From concept to delivery, their team of experts collaborates closely with customers to exceed expectations, providing invaluable support and expertise at every stage.

In summary, SourcifyChina is a leading provider of custom metal products and projects, leveraging the strength of the world’s strongest metals. Their advanced manufacturing techniques, commitment to sustainability, and focus on customer satisfaction set them apart in the industry. With an unwavering dedication to quality and innovation, they continue to push the limits of engineering, delivering exceptional solutions that stand the test of time.

SourcifyChina Strongest Metals is a pioneering force in the global metal industry, renowned for its exceptional quality and advanced metallurgical techniques. Based in China’s industrial heartland, the company specializes in supplying high-strength metals and alloys, catering to diverse sectors such as aerospace, automotive, construction, and advanced manufacturing. With a robust commitment to innovation and sustainability, SourcifyChina Strongest Metals leverages state-of-the-art technology and rigorous quality control processes to produce metals that meet the stringent international standards. Their extensive product range, including titanium, tungsten, and ultra-high-strength steels, is engineered to deliver unrivaled durability, performance, and reliability. By fostering strategic partnerships and maintaining an extensive distribution network, SourcifyChina ensures timely delivery and exceptional service across the globe. This dedication to excellence has solidified its reputation as a global leader in the metallurgical industry, driving growth, and setting new benchmarks for quality and sustainability.

In the realms of Aerospace, Defense, and Marine applications, the demand for the strongest metals is paramount, as these industries require materials that can withstand extreme conditions while maintaining structural integrity. In aerospace, strong metals such as titanium alloys and high-strength steel are crucial for manufacturing critical components like airframes, landing gear, and turbine engines. These metals not only provide the necessary strength-to-weight ratio, enhancing fuel efficiency and performance, but they also offer exceptional resistance to fatigue and corrosion, thereby extending the lifespan of aircraft and reducing maintenance costs. Furthermore, advancements in metallurgy, such as the incorporation of lightweight composites reinforced with strong metal matrices, are pushing the boundaries of aircraft design, enabling faster, more durable, and safer air travel.

In the defense sector, the application of the strongest metals is vital for producing military vehicles, armor, and weaponry that can endure the rigors of combat and extreme environments. For instance, high-hardness steel and tungsten alloys are frequently used in the construction of armored vehicles and protective gear due to their superior ballistic resistance and durability. Additionally, superalloys composed of nickel, cobalt, and other robust metals play a critical role in the development of advanced missile and rocket systems, delivering unmatched performance in high-stress scenarios. Similarly, in marine applications, metals like stainless steel and aluminum-bronze alloys are highly sought after for constructing hulls, propellers, and subsea infrastructure. These metals provide essential properties such as high tensile strength, excellent corrosion resistance, and the ability to endure prolonged exposure to saltwater, ensuring the longevity and reliability of marine vessels and subsea equipment. The use of such high-performance metals is indispensable in these high-stakes sectors, where safety, efficiency, and durability are non-negotiable.

In the automotive industry, the application of the strongest metals, such as high-strength steel, titanium alloys, and advanced aluminum composites, has revolutionized vehicle construction and performance. These metals offer exceptional durability and crash resistance, significantly enhancing passenger safety. High-strength steel, commonly used in chassis and body structures, provides a robust framework capable of absorbing and distributing impact forces during collisions, thereby protecting occupants. Meanwhile, titanium alloys, known for their high strength-to-weight ratio and corrosion resistance, are increasingly being utilized in components such as connecting rods, valve springs, and exhaust systems to reduce weight and improve engine efficiency. The integration of strong metals not only contributes to safer, lighter, and more fuel-efficient vehicles but also extends their operational life, reducing the need for frequent replacements and maintenance.

In the electronics sector, the strongest metals, including tungsten, molybdenum, and tantalum, play a crucial role in enhancing component performance and reliability. Tungsten and molybdenum, for instance, are incorporated into electrodes and interconnects due to their excellent electrical conductivity and high melting points, ensuring efficient and stable operation in high-temperature environments. Tantalum, known for its exceptional resistance to corrosion and fatigue, is widely used in capacitors and resistors within electronic circuits, providing reliable storage and regulation of electrical energy. Additionally, the robust nature of these metals enables the development of compact and miniaturized components without compromising performance or durability, driving advancements in portable and wearable technologies. The incorporation of the strongest metals into electronic devices ensures longevity, reduces the risk of failure, and supports the continual push towards smaller, more powerful, and more reliable electronic innovations.

In the realm of construction, the application of the strongest metals offers unparalleled benefits in terms of durability, resilience, and structural integrity. Steel, specifically high-strength variants like TMT (Thermo-Mechanically Treated) steel and weathering steel, is extensively used in skyscrapers, bridges, and monumental structures due to its exceptional tensile strength and ability to withstand extreme conditions. Stainless steel is another prominent contender, valued not only for its strength but also for its resistance to corrosion, making it ideal for both functional and aesthetic purposes in public infrastructure. Titanium, although more expensive, finds niche applications in construction where both strength and weight are critical factors. For example, it is used in fasteners, components in high-rise buildings, and in seismic retrofitting projects. These metals ensure that structures can endure substantial load, resist natural calamities, and have prolonged lifespans, thereby making construction projects more reliable and cost-effective over long-term horizons.

In the energy sector, the strongest metals are indispensable, especially in applications that demand robustness and reliability. High-strength alloys, including Inconel and Hastelloy, are vital in the construction of power plants, particularly in high-temperature areas such as boilers, reactors, and turbines. These metals not only withstand extreme thermal and mechanical stress but also resist oxidation and corrosion, ensuring the efficient and safe operation of energy facilities. For renewable energy installations, such as wind turbines and solar power plants, the need for lightweight yet sturdy materials brings titanium and advanced aluminum alloys to the forefront. These metals help in reducing the overall mass while maintaining structural strength, leading to improved efficiency and longevity of the installations. Thus, the use of the strongest metals in the energy sector significantly contributes to the reliable, efficient, and sustainable generation and distribution of energy.

The industrial equipment industry relies heavily on the application of the strongest metals to enhance durability, performance, and safety. Metals such as tungsten, titanium, and certain high-strength steel alloys are integral components in the manufacturing of machinery, heavy-duty vehicles, and structural frameworks. Tungsten’s exceptional hardness and high melting point make it invaluable for cutting tools, mining equipment, and military applications where extreme conditions are prevalent. Titanium, known for its impressive strength-to-weight ratio and corrosion resistance, is widely used in aerospace, marine, and chemical industries to construct robust yet lightweight components such as shafts, valves, and heat exchangers. High-strength steel alloys like maraging steel and T1 steel play crucial roles in the construction of bridges, skyscrapers, and industrial plants, providing the necessary tensile strength and resilience to withstand massive loads and harsh environments.

These advanced metals not only contribute to the structural integrity of industrial equipment but also extend their operational lifespan and efficiency. For instance, incorporating maraging steel in the production of mold tooling and die casting significantly enhances wear resistance and reduces the frequency of maintenance, leading to increased production efficiency and lower operational costs. In the energy sector, the use of durable metals like Inconel, a nickel-chromium-based superalloy, in turbine blades and power generation systems ensures optimal performance at high temperatures and pressures. This advancement in material science not only elevates the performance standards of various industrial applications but also fosters innovation, enabling the development of more resilient and efficient equipment. By leveraging the unique properties of the strongest metals, the industrial equipment industry continually pushes the boundaries of what is possible, driving progress and economic growth.

The use of the strongest metals in medical device applications has significantly advanced the field of medical technology, offering enhanced durability, biocompatibility, and performance. Titanium and its alloys, in particular, stand out due to their exceptional strength-to-weight ratio, resistance to corrosion, and biocompatibility with human tissues. This makes them ideal for implants such as joint replacements, dental implants, and bone plates, where long-term reliability and minimal adverse reactions are paramount. Additionally, titanium’s non-magnetic properties also allow for safe use in patients requiring MRI scans, further broadening its applicability in the medical field.

Another robust metal frequently employed in medical devices is cobalt-chromium alloy. Known for its incredible hardness and wear resistance, this alloy is widely used in orthopedic implants, such as hip and knee replacements, and in the fabrication of cardiovascular stents. Its high fatigue strength ensures that these implants can withstand the repetitive stress and strain they are subjected to over years of use. The blend of cobalt and chromium not only provides strength but also offers excellent corrosion resistance and biocompatibility, ensuring that the devices remain safe and functional inside the human body. Together, these strong metals play a crucial role in improving patient outcomes and extending the lifespan and reliability of medical devices.

Machining and manufacturing applications often rely on the use of the strongest metals to create components that can withstand extreme conditions and heavy loads. Metals like tungsten, titanium, and high-strength steel are pivotal in industries such as aerospace, automotive, and defense due to their robust mechanical properties. For example, tungsten’s high melting point and tensile strength make it indispensable in the production of cutting tools and heavy machinery that operate under high-stress conditions. Titanium, known for its excellent strength-to-weight ratio, is extensively used in aircraft frames and engine components, enhancing performance and fuel efficiency while maintaining structural integrity.

In the manufacturing sector, high-strength steels are crucial for constructing durable and reliable infrastructure and machinery. These metals contribute significantly to the longevity and safety of manufactured products, from bridges and buildings to consumer electronics. Precision machining techniques, such as CNC (Computer Numerical Control) milling and laser cutting, are essential for shaping these tough metals into intricate and precise forms required by advanced applications. Utilizing the strongest metals not only ensures superior performance but also pushes the boundaries of what is technologically possible, paving the way for innovative solutions across various engineering fields.

Q: What types of metals does SourcifyChina factory specialize in?

A: SourcifyChina factory specializes in a wide range of metals including steel, aluminum, titanium, and various alloys to meet diverse industry needs.

Q: How does SourcifyChina ensure the quality of the metals?

A: SourcifyChina follows strict quality control protocols including advanced testing methods like X-ray fluorescence (XRF) analysis, tensile testing, and third-party audits to ensure high quality.

Q: Can SourcifyChina handle custom metal manufacturing projects?

A: Yes, SourcifyChina offers custom manufacturing services tailored to your specifications, including custom alloys, special treatments, and unique design requirements.

Q: What certifications does SourcifyChina hold?

A: SourcifyChina holds various international certifications such as ISO 9001, ISO 14001, and OHSAS 18001, ensuring adherence to global standards in quality and safety.

Q: What is the lead time for orders?

A: Lead times vary depending on the complexity and quantity of the order. Generally, it ranges from 2 to 8 weeks.

Q: Does SourcifyChina offer prototypes and samples?

A: Yes, prototypes and samples can be provided for evaluation and approval before full-scale production.

Q: What are the minimum order quantities (MOQ)?

A: MOQs vary depending on the metal type and specific project requirements. Please contact our sales team for detailed information.

Q: How does pricing work at SourcifyChina?

A: Pricing is determined based on the type of metal, complexity of the work, and order volume. Custom quotes are provided to ensure competitive pricing.

Q: What industries does SourcifyChina serve?

A: SourcifyChina serves a broad spectrum of industries, including aerospace, automotive, construction, medical, and consumer electronics.

Q: How can I place an order or get a quote?

A: You can place an order or request a quote by contacting our customer service team via email, phone, or through our website contact form.

Q: Is international shipping available?

A: Yes, SourcifyChina offers international shipping with various logistics partners to ensure timely and safe delivery worldwide.

Q: What kind of after-sales support does SourcifyChina provide?

When sourcing the strongest metals for manufacturing from a factory like SourcifyChina, it’s key to ensure quality, reliability, and cost-effectiveness. Here are essential tips to maximize your acquisition process:

1. Define Specifications Clearly:

– Material Grade: Identify the specific grades of metals needed (e.g., titanium, tungsten, or high-strength steel).

– Mechanical Properties: Specify requirements like tensile strength, hardness, and resistance to corrosion.

2. Supplier Verification:

– Factory Audits: Conduct thorough factory audits to assess production capabilities.

– Certifications: Verify certifications such as ISO 9001, which indicate compliance with quality management standards.

3. Quality Assurance:

– Sample Testing: Request sample products for testing to analyze metal properties and quality.

– Inspection Protocols: Establish rigorous inspection protocols, both pre- and post-production.

4. Cost Analysis:

– Quote Comparison: Obtain detailed quotes from multiple suppliers to ensure competitive pricing.

– Total Landed Cost: Consider shipping, tariffs, and customs duties to calculate the total cost.

5. Communication:

– Clear Communication Channels: Maintain clear and frequent communication with the supplier to avoid misunderstandings.

– Technical Support: Ensure the supplier can provide technical support and is responsive to inquiries.

6. Logistics and Delivery:

– Lead Times: Confirm production lead times and delivery schedules to ensure they meet your timelines.

– Freight Options: Select reliable freight options and consider partnering with a known logistics provider.

7. Sustainability:

– Environmental Standards: Opt for suppliers that follow environmental management practices and sustainability protocols.

By following these tips, you can navigate the complexities of sourcing high-strength metals from SourcifyChina, ensuring that your manufacturing process benefits from top-quality materials, timely delivery, and cost-efficiency.

Sure, here are some frequently asked questions (FAQ) about sourcing the strongest metals from SourcifyChina factory along with their answers:

Q1: What types of strong metals does SourcifyChina factory supply?

A1: SourcifyChina factory supplies a variety of strong metals, including titanium, tungsten, high-strength steel alloys, and specialized aluminum alloys. These metals are known for their exceptional strength-to-weight ratios and durability.

Q2: How can I ensure the quality of metals sourced from SourcifyChina factory?

A2: SourcifyChina factory adheres to international quality standards such as ISO 9001 and provides relevant certifications and test reports for each batch of metal supplied. We also offer inspection services and third-party quality audits to verify the material properties.

Q3: What is the minimum order quantity (MOQ) for metals from SourcifyChina factory?

A3: The minimum order quantity varies depending on the type of metal and its specifications. Generally, MOQs are set to ensure cost-efficiency in production and shipping. Specific details can be provided upon inquiry.

Q4: Can SourcifyChina factory customize metal alloys according to my requirements?

A4: Yes, we offer customization services for metal alloys based on your specific needs. Our engineering team works closely with clients to develop tailored solutions that meet exact specifications.

Q5: What are the lead times for orders placed with SourcifyChina factory?

A5: Lead times depend on the type of metal, order quantity, and customization requirements. Typically, standard orders are processed within 4-6 weeks, whereas customized orders might take longer. Accurate lead times will be provided upon order confirmation.

Q6: Is international shipping available, and what are the shipping costs?

A6: Yes, SourcifyChina factory offers international shipping. Shipping costs depend on the destination, weight, and volume of the order. We provide competitive shipping rates and work with reputed logistics partners to ensure timely delivery.

Q7: How can I place an order with SourcifyChina factory?

A7: Orders can be placed by contacting our sales team through our website or email. We’ll guide you through the process, including specifying your requirements, receiving a quote, and confirming your order details.

Sourcing the strongest metals from a reputable factory such as SourcifyChina requires strategic planning and effective communication. Here are some tips:

1. Research and Verification:

– Background Check: Verify the factory’s reputation through reviews, industry certifications, and client testimonials.

– Product Portfolio: Ensure SourcifyChina offers metals like tungsten, titanium, or high-grade steel for your needs.

2. Specifications and Requirements:

– Detail Clarity: Clearly outline your metal requirements, including strength, durability, and specific applications.

– Sample Requests: Obtain metal samples to assess quality before large-scale ordering.

3. Communication:

– Language and Time Zones: Be mindful of potential language barriers and time zone differences. Use clear and concise language.

– Regular Updates: Maintain regular communication to keep track of production progress and address issues promptly.

4. Quality Assurance:

– Certifications: Ensure materials meet international standards (e.g., ISO, ASTM).

– Third-Party Inspection: Hire independent inspectors to verify quality.

5. Cost and Payment:

– Transparent Pricing: Make sure there’s a clear breakdown of costs, including raw material, manufacturing, and logistics.

– Secure Payments: Use secure and reliable payment methods to protect your transactions.

6. Logistics and Shipping:

– Shipping Arrangements: Discuss logistics early, including packaging and freight options to prevent delays.

– Customs Compliance: Ensure all documentation is accurate to avoid customs issues.

7. Long-term Relationship:

– Reliable Partnership: Build a strong, trustworthy relationship for future collaborations.

– Feedback Loop: Provide feedback for continuous improvement and better service.

By adhering to these tips, you can effectively source the strongest metals from SourcifyChina, ensuring high quality and reliability for your projects.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.