Reliable Comparison by SourcifyChina: Surgical Steel vs Titanium in Factory Manufacturing

In this authoritative guide, SourcifyChina provides a reliable comparison of surgical steel and titanium, evaluating their advantages, applications, and costs in factory settings to help manufacturers make informed material choices.

SourcifyChina Factory excels in providing high-quality surgical steel and titanium products, thanks to their rigorous quality control processes. The factory ensures each item meets international standards, offering buyers unparalleled reliability.

Another key reason to choose SourcifyChina is their competitive pricing. By leveraging advanced manufacturing techniques and strategic sourcing, they can offer top-tier materials at affordable rates, optimizing cost-efficiency for buyers.

Moreover, SourcifyChina prides itself on excellent customer service. Their dedicated team provides comprehensive assistance, ensuring smooth transactions and addressing any concerns promptly, fostering a seamless purchasing experience for buyers.

Additionally, the factory boasts a strong track record of timely deliveries. Understanding the importance of meeting project deadlines, SourcifyChina ensures that all shipments are handled with utmost precision and speed.

Furthermore, SourcifyChina Factory is known for its commitment to sustainability. They integrate eco-friendly practices throughout their operations, minimizing environmental impact and appealing to eco-conscious buyers looking for responsible suppliers.

In summary, SourcifyChina Factory stands out for its high-quality products, competitive pricing, exceptional customer service, reliable delivery, and sustainable practices. This makes them the ideal choice for buyers seeking surgical steel and titanium from China, ensuring satisfaction and excellence in every purchase.

Surgical steel and titanium are popular materials for body jewelry and surgical implants. Surgical steel is durable and corrosion-resistant, making it ideal for various applications. Titanium is lightweight, hypoallergenic, and extremely strong, suitable for sensitive individuals.

Surgical Steel:

– Composition: Alloy primarily of iron, chromium, and nickel.

– Durability: Highly durable and corrosion-resistant.

– Cost: Generally more affordable.

– Hypoallergenic: Less hypoallergenic than titanium but suitable for most users.

– Weight: Heavier than titanium.

– Magnetic Property: Can be magnetic.

Titanium:

– Composition: Pure metal or titanium alloy.

– Weight: Lightweight, nearly 50% lighter than steel.

– Hypoallergenic: Highly hypoallergenic, suitable for sensitive skin.

– Durability: Extremely strong and corrosion-resistant.

– Strength-to-Weight Ratio: Superior compared to surgical steel.

– Cost: Typically more expensive.

– Magnetic Property: Non-magnetic.

Choosing between surgical steel and titanium depends on individual needs, skin sensitivity, and budget. Surgical steel is cost-effective and durable, while titanium offers lightweight and hypoallergenic properties.

Surgical steel and titanium are both commonly used in medical implants, but each has distinct properties. Surgical steel is renowned for its strength and corrosion resistance, while titanium is celebrated for being lightweight and biocompatible.

– Strength and Durability: Surgical steel is exceptionally strong, offering high durability, especially for load-bearing implants.

– Corrosion Resistance: The chromium content in surgical steel provides robust resistance to rust and corrosion.

– Cost-Effective: Generally, surgical steel is more affordable than titanium, making it a suitable option for various procedures.

– Common Uses: Employed in surgical instruments, bone plates, and screws.

Titanium:

– Lightweight: Titanium offers superior strength-to-weight ratio, reducing patient discomfort and allowing for easier mobility.

– Biocompatibility: Titanium is highly compatible with the human body, often resulting in fewer allergic reactions and better osseointegration with bone.

– Corrosion Resistance: Just like surgical steel, titanium resists corrosion but also offers added resistance to bodily fluids.

– Long-term Implants: Ideal for long-term implants such as joint replacements, dental implants, and pacemaker casings.

Application

Considerations:

– Patient Allergies: Titanium is less likely to cause allergic reactions, important for patients with sensitivities to metals.

– Weight Sensitivity: Titanium’s lighter weight makes it preferable for joint replacements and implants in areas subject to movement.

– Bone Healing: Better osseointegration with titanium suggests a quicker and stronger bond between bone and implant.

Both materials are valuable in medical applications, with the choice depending on specific patient needs and surgical requirements. Each material’s unique properties make it suitable for different types of implants, ensuring the best outcomes in medical procedures.

SourcifyChina provides high-quality surgical steel, known for its durability and corrosion resistance. It contains nickel, chromium, and molybdenum, which add strength and enhance its ability to withstand stress. This composition is ideal for creating medical devices and body implants that can withstand sterilization and multiple uses.

In contrast, titanium is lauded for its light weight and superior biocompatibility. Titanium resists both rust and bodily fluids, making it a preferred choice for implants directly in contact with bone or tissue. It also showcases incredible strength, reducing the likelihood of device failure in critical applications.

When considering cost, surgical steel tends to be more affordable than titanium. This cost-effectiveness makes it a popular choice for a wide range of surgical instruments and tools, contributing to its widespread use in various medical settings. While titanium is often considered premium, its extended lifespan and reduced risk of rejection often justify the higher cost.

Titanium holds an advantage over surgical steel when long-term implantation is needed, largely due to its higher resistance to bodily degradation and lack of nickel, which can cause allergies for some patients. However, surgical steel’s robust performance makes it an excellent choice for many other medical applications.

In summary, both surgical steel and titanium from SourcifyChina offer unique advantages that meet specific medical requirements. Surgical steel’s cost-effectiveness and durability make it suitable for a range of uses, while titanium’s light weight and biocompatibility are ideal for implants. Choosing between the two involves considering the specific needs and restrictions of the medical procedure, allowing healthcare professionals to make informed decisions based on material properties.

SourcifyChina offers rigorous quality control in manufacturing surgical steel and titanium products. Surgical steel, typically 316L, is known for its resistance to rust and corrosion. Titanium, specifically Ti-6Al-4V, is favored for its incredible strength-to-weight ratio and biocompatibility. Both materials undergo stringent inspections to ensure they meet international medical standards.

Raw materials are procured from certified suppliers and tested for purity. XRF and spectrometry are used to confirm the precise chemical composition. For surgical steel, austenitic structure and low carbon content are verified to ensure durability and safety in medical applications.

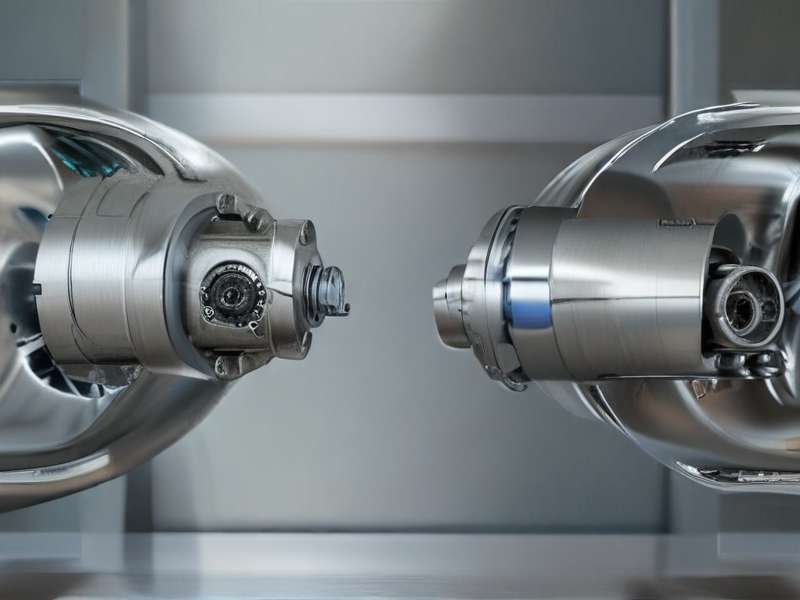

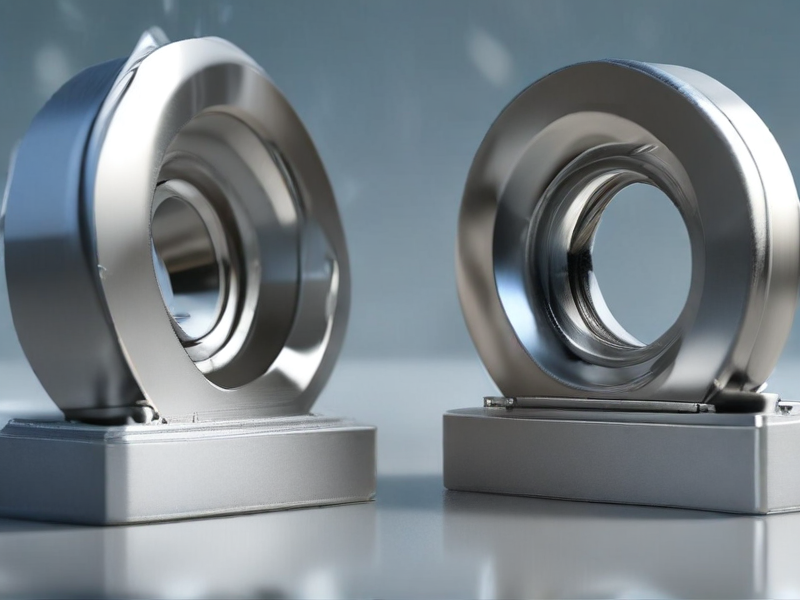

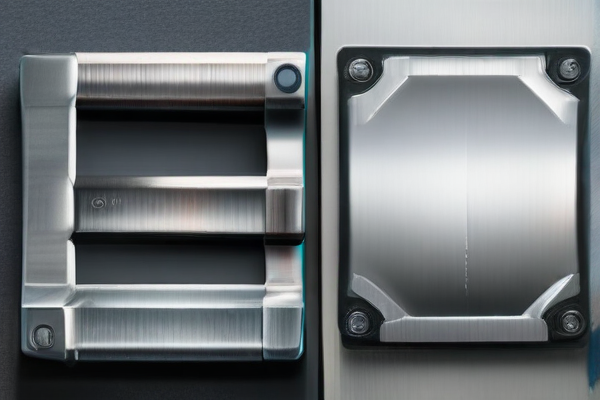

During the manufacturing process, both materials are subjected to CNC machining, laser cutting, and precision welding. SourcifyChina employs advanced technologies to maintain tight tolerances and minimal defects. Each component is meticulously examined under magnification to detect any micro-cracks or irregularities.

Post-manufacturing, products go through several cleaning processes to eliminate contaminants. Surgical steel items are typically passivated while titanium products may undergo anodizing treatments. An additional layer of quality check involves simulated usage environments to test for durability and performance.

Finally, all products are packaged in sterile environments to maintain their readiness for medical use. SourcifyChina’s emphasis on quality control ensures that both surgical steel and titanium products meet the highest standards, offering reliability and safety for medical professionals worldwide.

SourcifyChina offers both surgical steel and titanium options for medical and consumer products. Surgical steel is often favored for its affordability and widespread availability. It’s utilized in instruments, implants, and everyday items like body jewelry due to its robustness and resistance to corrosion.

On the other hand, titanium is renowned for its exceptional strength-to-weight ratio and biocompatibility. This makes it highly suitable for long-term implants and advanced surgical tools. It’s also hypoallergenic, reducing the risk of allergic reactions, which is particularly advantageous in sensitive applications.

Both materials undergo rigorous quality control to meet international standards. SourcifyChina ensures that surgical steel products are meticulously polished to maintain a smooth surface, minimizing the risk of bacterial contamination. This attention to detail is vital in a healthcare setting where patient safety is paramount.

Meanwhile, titanium items from SourcifyChina are precision-engineered to take full advantage of the material’s unique properties. These products often come anodized, which not only enhances their durability but also allows for customization in terms of color and finish.

In summary, SourcifyChina’s capabilities in offering both surgical steel and titanium products ensure that clients receive the material best suited for their needs. Whether the priority is cost-efficiency, hypoallergenic properties, or long-term durability, SourcifyChina provides high-quality solutions that adhere to strict medical and industry standards. Their attention to detail and commitment to quality make them a reliable partner for various applications.

Surgical steel and titanium are both popular materials for medical implants, body jewelry, and other surgical instruments due to their unique properties. However, each has distinct benefits.

– Durability:

– Surgical steel is exceptionally robust and resistant to wear and tear.

– Titanium is renowned for its high strength-to-weight ratio, making it incredibly durable while remaining lightweight.

– Biocompatibility:

– Surgical steel is biocompatible but may contain minimal amounts of nickel, potentially causing allergic reactions in sensitive individuals.

– Titanium is fully biocompatible and hypoallergenic, making it ideal for patients with metal allergies.

– Corrosion Resistance:

– Surgical steel offers excellent corrosion resistance but might show some signs of wear over extended periods.

– Titanium boasts superior resistance to corrosion, even from body fluids and salts, enhancing the longevity of implants.

– Weight:

– Surgical steel is heavier, which may offer a more substantial feel in surgical instruments.

– Titanium’s lightweight nature makes it beneficial for implants and body jewelry, reducing strain on the body.

– Cost:

– Surgical steel is generally more affordable, making it a cost-effective choice for surgical instruments and mid-range implants.

– Titanium tends to be more expensive, reflecting its advanced properties and benefits.

– Magnetic Properties:

– Surgical steel may be slightly magnetic, which could interfere with MRI scans.

– Titanium is non-magnetic, ensuring MRI compatibility and making it safer for use in medical imaging contexts.

In conclusion, both surgical steel and titanium have unique benefits that make them suitable for different applications. Choosing between them depends on specific needs such as allergy concerns, weight considerations, and cost.

When it comes to selecting materials for implants, surgical steel and titanium are two prominent choices, each offering unique advantages.

– Corrosion Resistance: Both materials exhibit high resistance to corrosion, but titanium excels in harsher environments.

– Biocompatibility: Titanium is notably more biocompatible, reducing the risk of allergic reactions or tissue rejection.

– Weight: Titanium is lighter than surgical steel, making it preferable for implants where weight is a consideration.

– Strength: Surgical steel offers excellent mechanical strength, though titanium provides a better strength-to-weight ratio.

– Durability: Both materials are durable, but titanium generally offers better long-term performance.

– Flexibility: Titanium has superior flexibility, making it ideal for dynamic or stress-bearing implants.

– Cost: Surgical steel tends to be more affordable compared to titanium, which can be a significant factor in material selection.

– Surface Finish: Surgical steel often has a smoother finish, which can be a benefit in reducing friction and wear in some applications.

– Surgical Applications: Both materials are extensively used in various surgical applications, but titanium’s properties make it especially suitable for bone replacements and dental implants.

SourcifyChina specializes in custom products and projects using surgical steel and titanium. These materials are renowned for their durability, corrosion resistance, and biocompatibility, making them ideal for a variety of applications, particularly in the medical field.

Surgical steel is a type of stainless steel specifically formulated for medical applications. It offers excellent strength, resistance to corrosion, and is relatively inexpensive. Its hypoallergenic properties make it suitable for surgical instruments and implants, ensuring patient safety.

Titanium, on the other hand, is lighter and possesses a higher strength-to-weight ratio compared to surgical steel. It’s exceptionally resistant to corrosion and exhibits superior biocompatibility, making it a preferred choice for implants and high-stress applications.

SourcifyChina’s custom products can address unique project requirements by leveraging the specific advantages of these materials. Whether it’s custom machinery parts, medical implants, or specialized instruments, their team ensures the highest quality standards and precise specifications.

What sets SourcifyChina apart is its commitment to tailored solutions. By understanding client needs and project specifications, they can recommend the most suitable material—surgical steel for budget-conscious, high-strength applications, or titanium for lightweight, highly durable needs.

In conclusion, whether employing surgical steel or titanium, SourcifyChina’s expertise in custom manufacturing ensures every project meets exacting industry standards. Their ability to deliver high-quality, durable, and biocompatible products makes them a trusted partner for specialized and demanding applications.

SourcifyChina is a prominent company specializing in the production and supply of high-quality surgical steel and titanium products for the global medical industry. By leveraging advanced manufacturing technologies and rigorous quality control measures, the company offers an extensive range of surgical instruments, implants, and medical devices designed to meet the stringent standards of healthcare professionals. SourcifyChina’s surgical steel products are renowned for their corrosion resistance, durability, and affordability, making them a popular choice for various medical procedures. On the other hand, their titanium offerings boast superior biocompatibility, lighter weight, and greater strength, making them ideal for applications where long-term implantation and patient comfort are paramount. Through continuous innovation and a commitment to excellence, SourcifyChina has established itself as a trusted partner for medical facilities worldwide, ensuring that each product not only meets but exceeds expectations in both performance and safety.

Surgical steel and titanium are two prominent materials utilized in aerospace, defense, and marine applications due to their exceptional properties. Surgical steel, a type of stainless steel, is renowned for its high corrosion resistance and strength. Primary uses in these sectors include structural components, fasteners, and tools that must endure harsh environments while maintaining structural integrity. In the marine industry, surgical steel’s resistance to seawater degradation makes it ideal for underwater structures and equipment. Aerospace and defense industries value its durability and cost-effectiveness, applying it in areas where moderate weight and high strength are critical.

Titanium, on the other hand, offers a unique combination of high strength-to-weight ratio, corrosion resistance, and biocompatibility. This makes it particularly advantageous in aerospace and defense applications where weight savings are paramount for fuel efficiency and performance. Titanium is employed in aircraft frames, engine components, and defense systems such as armor plating and missile casings. Its marine applications include components for submarines and ships that require superior corrosion resistance and strength without the added weight. While titanium is more expensive than surgical steel, its enhanced performance characteristics often justify the higher cost in critical, high-performance applications.

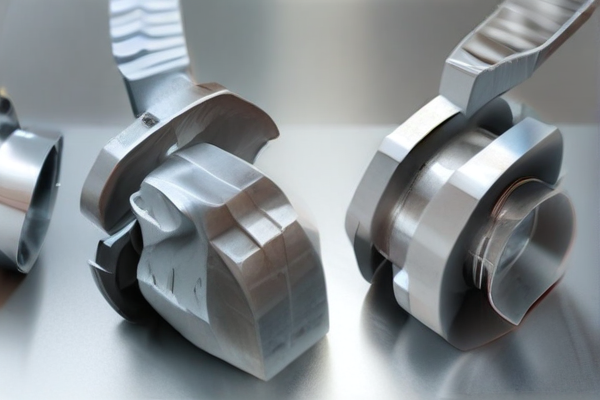

In the realm of automotive applications, both surgical steel and titanium have carved out unique niches thanks to their distinctive properties. Surgical steel, known for its excellent corrosion resistance and durability, is often employed in components that demand reliable performance under harsh conditions. For example, exhaust systems and certain engine components benefit from surgical steel’s resilience to rust and high temperatures. Additionally, its affordability compared to titanium makes it a cost-effective choice for various high-performance automotive parts. On the other hand, titanium is revered for its exceptional strength-to-weight ratio, making it a prime candidate for applications where reducing weight without compromising strength is crucial. This includes critical components such as suspension systems and high-performance chassis parts. Although more expensive, titanium’s contribution to enhancing vehicle performance and fuel efficiency justifies its use in top-end and competitive automotive fields.

Electronics applications also see a distinct utilization of surgical steel and titanium, with each material offering noteworthy advantages. Surgical steel is highly favored for manufacturing casings and enclosures for electronic devices due to its robustness and excellent resistance to wear and tear. The material’s anti-magnetic property is also beneficial, ensuring that electronic devices encased in surgical steel are shielded from electromagnetic interference. Conversely, titanium’s prominent role in the electronics industry is driven by its light weight and high strength, alongside its non-corrosive and biocompatible nature, which are particularly advantageous for wearable technology and medical devices. Titanium’s ability to maintain structural integrity while being lightweight makes it ideal for compact, high-performance electronic applications, such as smartphones, laptops, and fitness trackers. While more costly, titanium’s use in premium electronic devices underscores its value in providing durability combined with a sleek, lightweight design.

Surgical steel and titanium are both prized for their exceptional properties, making them valuable materials in both construction and energy applications. Surgical steel, particularly grades like 316L, is renowned for its corrosion resistance, strength, and biocompatibility. In construction, it is often used in structures that demand high durability and minimal maintenance, such as bridges and skyscrapers. Its corrosion-resistant properties make it ideal for environments exposed to harsh weather conditions or chemical agents. Additionally, surgical steel’s robustness and aesthetic appeal contribute to its use in architectural elements, railings, and fixtures, combining functionality with design.

Titanium, on the other hand, stands out for its remarkable strength-to-weight ratio and resistance to extreme temperatures. In the energy sector, titanium is indispensable, especially in renewable energy infrastructures such as wind turbines and hydroelectric power stations. Its stability under high-stress and corrosive conditions ensures longevity and efficiency in these applications. Moreover, titanium’s non-magnetic properties are highly advantageous in certain construction scenarios, such as in buildings that house sensitive magnetic field equipment. Both materials serve pivotal roles across sectors, with surgical steel offering excellent endurance and titanium providing unmatched strength and versatility, reflecting the evolving needs of modern engineering and sustainability efforts.

In the industrial equipment sector, the choice between surgical steel and titanium often hinges on their distinct properties tailored for specialized applications. Surgical steel, primarily an alloy of iron, carbon, and chromium, is renowned for its robustness and corrosion resistance. These attributes make it a preferred material in the manufacturing of high-precision tools and components that are exposed to harsh operational environments, such as chemical processing plants and marine applications. The chromium content in surgical steel provides a self-healing oxide layer which offers excellent resistance to rust and chemical degradation, prolonging the lifecycle of equipment and reducing maintenance costs.

On the other hand, titanium stands out for its exemplary strength-to-weight ratio and exceptional corrosion resistance, even in extreme conditions. These properties make titanium an invaluable material for applications requiring lightweight and durable components, such as aerospace, automotive, and medical devices. In industrial settings, titanium is often used for high-performance machinery parts and equipment subjected to high stresses and corrosive environments, like heat exchangers and turbine blades. Furthermore, its biocompatibility and non-reactive nature enhance its suitability for equipment in the pharmaceutical and food processing industries where contamination is a critical consideration. Thus, the selection between surgical steel and titanium ultimately depends on the specific performance requirements and environmental challenges of the industrial application at hand.

The application of materials in medical devices, particularly surgical implants, is critical to patient outcomes and long-term health. Surgical steel and titanium are two primary materials utilized in various medical devices, each offering distinct advantages. Surgical steel, typically an alloy of iron with chromium, nickel, and molybdenum, is renowned for its high tensile strength, corrosion resistance, and affordability. It is commonly used in orthopedic implants, surgical instruments, and certain dental devices. However, one of the limitations of surgical steel is the potential for nickel allergies in some patients, which can lead to adverse reactions such as inflammation or hypersensitivity. Additionally, surgical steel’s relatively higher density compared to other materials can pose an issue in weight-sensitive applications.

Titanium, on the other hand, is often preferred for its superior biocompatibility and lower density, making it lighter while still maintaining substantial strength. It boasts excellent corrosion resistance, particularly in the presence of body fluids, and is less likely to provoke allergic reactions, as it is generally more inert. This makes titanium an ideal candidate for long-term implants, including bone plates, joint replacements, and dental implants. Moreover, titanium’s elasticity more closely matches that of human bone, which can reduce stress shielding and promote better integration with the body’s natural tissues. However, the main downside to titanium is its higher cost and the complexity of manufacturing, which can limit its widespread use despite its many clinical benefits. Therefore, the choice between surgical steel and titanium in medical devices often hinges on a careful balance between patient-specific factors, application requirements, and economic considerations.

Machining and manufacturing surgical tools and implants involve rigorous demands for precision, biocompatibility, and durability. Surgical steel, primarily composed of stainless steel alloy, has long been a staple in the medical field due to its strength, corrosion resistance, and ease of sterilization. The machining process for surgical steel is relatively straightforward owing to its predictable behavior under cutting and forming operations. Manufacturers leverage advanced CNC (computer numerical control) machinery to produce finely crafted surgical instruments such as scalpels, forceps, and retractors. The consistency in material properties allows for repeatability and high-quality standard production, critical in medical applications where precision is non-negotiable.

On the other hand, titanium has gained prominence in the manufacturing of orthopedic implants and prosthetics due to its superior biocompatibility and strength-to-weight ratio. Titanium is notably lighter and more resistant to fatigue, making it ideal for long-term implantation within the human body. However, machining titanium presents more challenges compared to surgical steel. Titanium’s low thermal conductivity requires specialized cutting tools and cooling techniques to prevent overheating and maintain tolerances. Despite these machining complexities, advances in technology, such as high-speed milling and electron beam machining, enable precise and efficient production of titanium components. In applications such as joint replacements, dental implants, and bone screws, titanium’s properties support long-term performance and patient outcomes, underscoring its crucial role in modern medical device manufacturing.

Sure, here are some frequently asked questions (FAQ) with answers regarding the quality of surgical steel vs. titanium work from SourcifyChina factory:

Q1: What are the main differences between surgical steel and titanium?

A1: Surgical steel is a type of stainless steel known for its durability and corrosion resistance, commonly used in medical devices. Titanium, on the other hand, is lighter yet equally strong and highly resistant to corrosion, making it ideal for implants and high-performance medical tools.

Q2: Which material is safer for medical use, surgical steel or titanium?

A2: Both materials are highly biocompatible and safe for medical use. However, titanium is often preferred for implants due to its lighter weight and excellent osseointegration properties, which means it bonds well with bone.

Q3: How does SourcifyChina ensure the quality of surgical steel and titanium products?

A3: SourcifyChina employs stringent quality control processes such as material certification, precision manufacturing, and extensive testing to meet international standards. They also perform biocompatibility tests and corrosion resistance evaluations on both materials.

Q4: What are the cost differences between surgical steel and titanium products?

A4: Titanium is generally more expensive than surgical steel due to its superior properties and more complex manufacturing processes. However, the long-term benefits in medical applications can justify the higher cost of titanium.

Q5: Can SourcifyChina customize products made from surgical steel and titanium?

A5: Yes, SourcifyChina offers customization services to meet specific design and application requirements. They work closely with clients to ensure that the final products meet the desired specifications and regulatory standards.

Q6: What is the typical lead time for manufacturing and shipping products from SourcifyChina?

A6: The lead time varies depending on the complexity of the project and order size. However, SourcifyChina aims to deliver prototypes within 4-6 weeks and larger orders within 8-12 weeks.

Q7: Does SourcifyChina provide certification and documentation for surgical steel and titanium products?

A7: Yes, SourcifyChina provides all necessary certifications and documentation, including material certificates, quality assurance reports, and compliance with international medical standards.

Q8: Are the surgical steel and titanium products tested for any allergens?

A8: Yes, all products undergo rigorous testing to ensure they are hypoallergenic and safe for medical use, minimizing any risk of allergic reactions in patients.

When choosing between surgical steel and titanium for manufacturing, there are several factors to consider, particularly if you are sourcing from a factory like SourcifyChina. Here are key tips to help guide your decision:

Material

Properties:

– Surgical Steel:

– Cost-Effective: Typically cheaper than titanium.

– Strength: Provides excellent durability and resistance to corrosion.

– Biocompatibility: Suitable for medical and jewelry applications but may cause allergic reactions in some individuals due to nickel content.

– Titanium:

– Lightweight: About 45% lighter than surgical steel, offering easier handling and comfort.

– High Strength-to-Weight Ratio: Strong and durable while being much lighter.

– Biocompatibility: Highly biocompatible and hypoallergenic, ideal for medical implants and high-end jewelry.

Manufacturing

Considerations:

– Machinability:

– Surgical steel is generally easier to machine, which could result in lower manufacturing costs.

– Titanium requires specialized equipment due to its hardness and lower machinability, potentially increasing manufacturing costs.

– Surface Finish:

– Both materials can achieve high-quality finishes, but titanium offers a more premium aesthetic, which can be a selling point for luxury products.

Sourcing

from SourcifyChina:

– Expertise: Ensure the factory has experience with both materials. This can impact the quality of the final product and the efficiency of production.

– Equipment and Technology: Verify that SourcifyChina is equipped with the latest technology to handle the specific demands of machining titanium or surgical steel.

– Cost vs. Quality: Weigh the cost benefits between the two materials. Titanium might be more expensive but offers superior biocompatibility and a lightweight advantage.

– Lead Time: Consider production and shipping times, as titanium might take longer due to more complex machining processes.

Conclusion:

Ultimately, your choice will depend on your specific application goals, budget constraints, and quality requirements. Both materials offer unique advantages, and partnering with a knowledgeable factory like SourcifyChina can help you navigate these factors effectively.

Sure, here’s a concise FAQ on sourcing surgical steel vs. titanium from SourcifyChina factory:

1. What are the main differences between surgical steel and titanium?

Surgical steel is an alloy of iron, carbon, and chromium, known for its durability and corrosion resistance. Titanium, lighter and equally strong, offers superior biocompatibility and is hypoallergenic.

2. Which is more cost-effective: surgical steel or titanium?

Generally, surgical steel is more cost-effective due to the lower cost of raw materials and simpler processing compared to titanium.

3. How does the manufacturing process differ for surgical steel and titanium?

Surgical steel involves traditional metalworking techniques like casting and milling. Titanium requires specialized equipment and processes such as vacuum arc remelting and precision machining, making it more complex and time-consuming to produce.

4. Can SourcifyChina factory customize products using both materials?

Yes, SourcifyChina factory offers customization services for both surgical steel and titanium products, including custom designs, sizes, and finishes to meet specific requirements.

5. Are there minimum order quantities (MOQs) for surgical steel and titanium products?

MOQs may vary based on the product type and complexity. Typically, products made from surgical steel have lower MOQs compared to those made from titanium due to material cost and manufacturing complexity.

6. What are the lead times for sourcing each material?

Lead times can vary; surgical steel products usually have shorter lead times (4-6 weeks) compared to titanium (6-8 weeks) due to differences in processing requirements.

7. How does SourcifyChina ensure the quality of surgical steel and titanium products?

SourcifyChina follows strict quality control measures, including material certification, precision testing, and final inspections to ensure the highest quality for both surgical steel and titanium products.

8. Are there any specific applications where surgical steel is preferred over titanium?

Surgical steel is preferred in applications where cost, strength, and durability are prioritized, such as surgical instruments and medical devices. Titanium is favored for implants and situations requiring high biocompatibility and lightweight properties.

9. Does SourcifyChina factory provide samples for both materials?

Yes, the factory can provide samples of both surgical steel and titanium products for evaluation before placing bulk orders.

10. How do I place an order with SourcifyChina for surgical steel or titanium products?

When sourcing materials like surgical steel and titanium from a supplier such as SourcifyChina, it’s essential to ensure quality, reliability, and cost-effectiveness. Here are some tips to help you make an informed decision:

1. Understand Material Properties:

– Surgical Steel: Known for its durability and corrosion resistance, ideal for implants and medical instruments.

– Titanium: Offers a higher strength-to-weight ratio and excellent biocompatibility, preferred for implants and high-performance medical devices.

2. Supplier Verification:

– Check if SourcifyChina has relevant certifications (ISO 13485, FDA approvals).

– Request material certificates to verify the origin and quality.

3. Communication:

– Clearly outline your requirements and specifications (grades, dimensions, tolerances).

– Use precise, technical language to avoid misunderstandings.

4. Quality Assurance:

– Ask for sample materials for testing.

– Ensure that SourcifyChina follows stringent quality control processes.

5. Pricing and MOQ:

– Compare costs for both materials; titanium is usually more expensive.

– Confirm minimum order quantities and lead times to align with your production schedule.

6. Customization:

– Verify if the factory can provide custom finishes or specific alloy compositions.

– Inquire about machining and additional processing services.

7. Logistics:

– Assess shipping times and costs.

– Ensure they offer reliable packaging to prevent damage during transit.

8. Sustainability:

– Review the factory’s environmental policies.

– Consider the recyclability and environmental impact of each material.

By carefully analyzing these factors, you can make a well-informed decision on whether surgical steel or titanium is more suitable for your needs, and ensure that SourcifyChina can meet your quality and logistical requirements.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.