Choosing SourcifyChina Factory for purchasing top-rated CNC routers from China ensures you access high-quality products at competitive prices. Their stringent quality assurance processes guarantee reliability and durability, reducing maintenance costs and downtime.

Experience exceptional customer service with SourcifyChina Factory. They provide personalized support, answering queries promptly and facilitating smooth transactions, ensuring customer satisfaction throughout the purchasing process.

Leverage SourcifyChina’s extensive industry expertise. They possess a deep understanding of CNC router technology and market trends, enabling them to offer informed recommendations, helping buyers make the best purchasing decisions.

Benefit from SourcifyChina Factory’s robust supply chain management. Their established network with reputable manufacturers ensures timely delivery and consistent product availability, preventing supply shortages and workflow interruptions.

Trust in their transparent pricing and policies. SourcifyChina Factory provides clear cost breakdowns, ensuring no hidden fees or unexpected expenses, fostering long-term buyer trust and confidence in every transaction.

Opting for SourcifyChina Factory for your CNC router needs means investing in unparalleled value, reliability, and expertise, ultimately empowering you to achieve operational excellence and business growth.

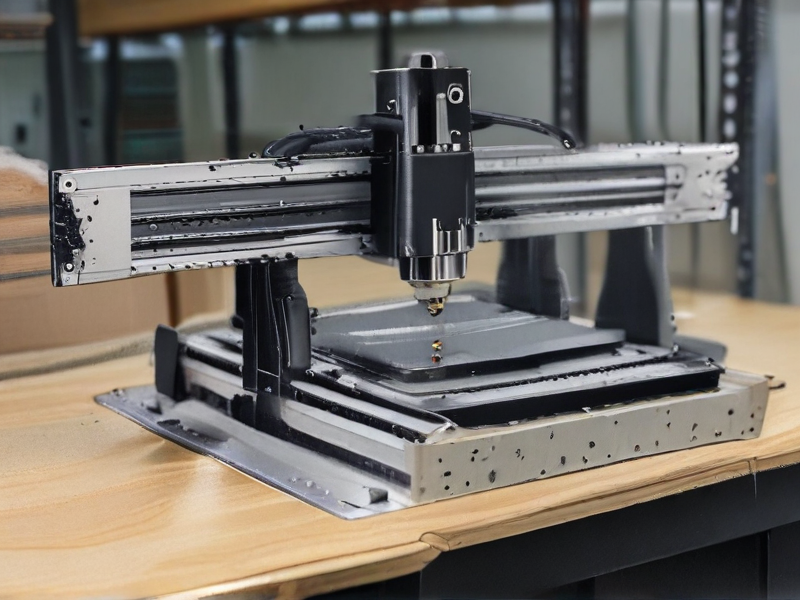

Top-rated CNC routers are versatile tools for woodworking, metalworking, and more, offering precision and efficiency. Popular types include industrial, desktop, and handheld models, catering to various project needs and budgets.

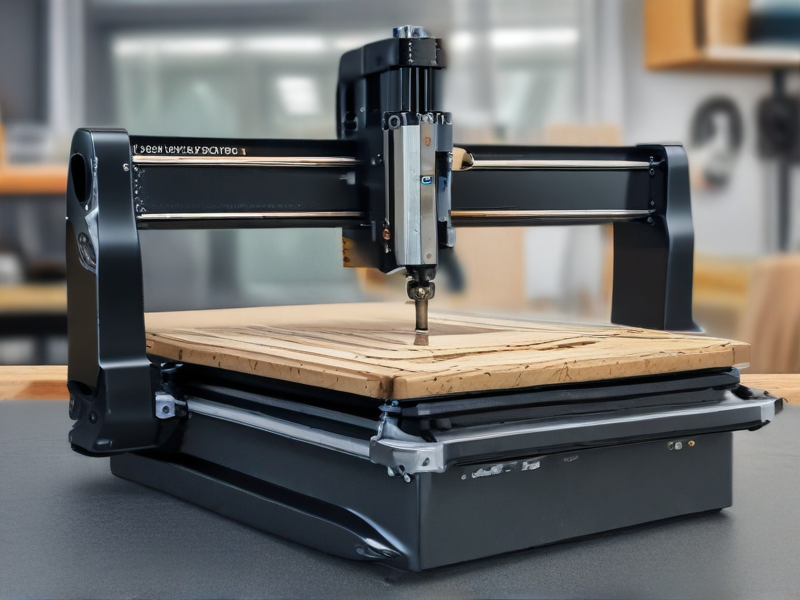

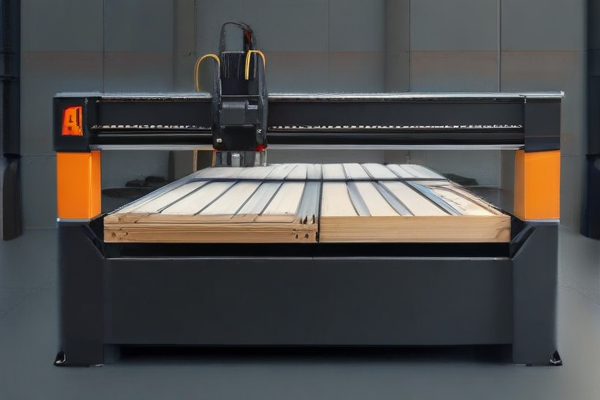

– Industrial CNC Routers: Ideal for large-scale production, offering high precision and durability.

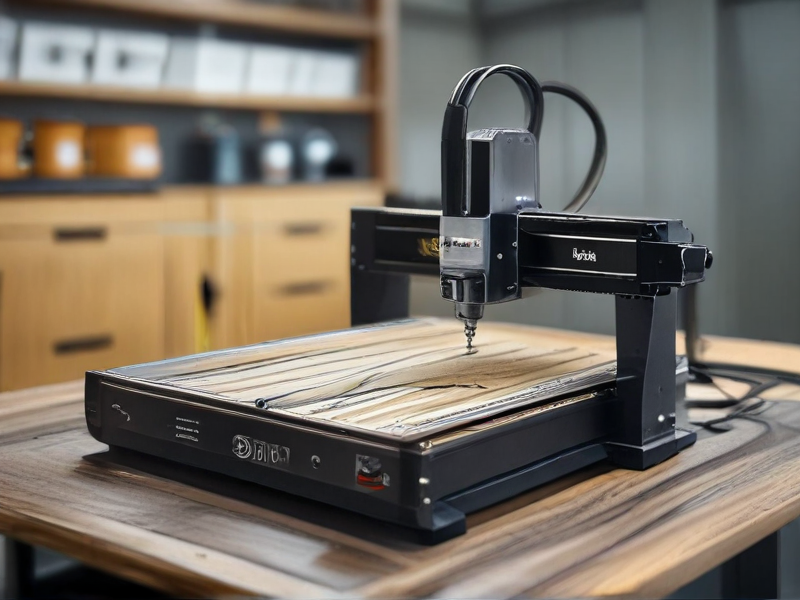

– Desktop CNC Routers: Compact and user-friendly, suitable for hobbyists and small workshops.

– Handheld CNC Routers: Portable options perfect for on-site jobs or detailed work on large pieces.

– 5-Axis CNC Routers: Provide complex cutting capabilities for intricate designs and multi-dimensional tasks.

– Benchtop CNC Routers: Convenient for smaller spaces, offering a balance between industrial and desktop functionalities.

– All-in-One CNC Routers: Combine multiple tools and features, streamlining the workflow for diverse projects.

– Shapeoko 4: User-friendly, expandable, and versatile for a variety of materials.

– X-Carve: Known for its open-source design, suitable for custom modifications.

– Avid CNC PRO Series: High precision and robust build, perfect for professional use.

– Next Wave Shark HD520: Compact yet powerful, ideal for detailed woodworking.

– BobsCNC Evolution 4: Affordable and easy to assemble, great for beginners.

– Maslow CNC: Large-format capabilities at a budget-friendly price.

– Sainsmart Genmitsu 3018-PROVer: Economical and adaptable, perfect for DIY enthusiasts.

– Laguna Tools IQ: Premium options with advanced features and high reliability.

When choosing a CNC router, consider the material compatibility, cutting area, software compatibility, and customer support. The best choice will depend on your specific needs, budget, and space constraints.

Top-rated CNC routers are essential tools in various industries due to their precision, versatility, and automation capabilities, which streamline manufacturing processes and improve product quality.

Applications for Top-Rated CNC Routers:

– Woodworking: Precision cutting, carving, and engraving on wood for furniture, cabinetry, and decorative items.

– Metal Fabrication: Producing intricate parts and components for machinery, automotive, and aerospace industries.

– Prototyping: Rapid development and testing of design prototypes in various materials.

– Sign Making: Creating detailed and durable signage, including intricate lettering and custom designs.

– Plastic and Foam Cutting: Shaping and cutting materials for packaging, display units, and other commercial uses.

– Composite Materials: Machining complex materials like carbon fiber for high-strength components.

– Jewelry Making: Crafting detailed and custom jewelry pieces with precision.

– PCB Manufacturing: Engraving and cutting printed circuit boards for electronics.

– Modeling: Creating architectural models, miniatures, and other detailed scale models.

– Art and Sculptures: Producing detailed art pieces and sculptures with intricate designs.

– Custom Gifts and Personalization: Creating custom designs on various materials for personalized gifts.

– Educational Use: Teaching CNC programming and manufacturing processes in academic settings.

– Automotive Customization: Making custom parts and accessories for vehicle modification and personalization.

– Medical Device Manufacturing: Producing precise components for medical instruments and devices.

– Boat Building: Crafting parts for marine applications with high accuracy and durability.

– Aerospace Components: Manufacturing lightweight and strong components for the aerospace industry.

SourcifyChina’s top-rated CNC routers are comprised of high-quality materials to ensure precision, durability, and reliable performance. Featuring aluminum alloy frames, they offer a perfect balance between strength and weight, providing stability during intricate operations.

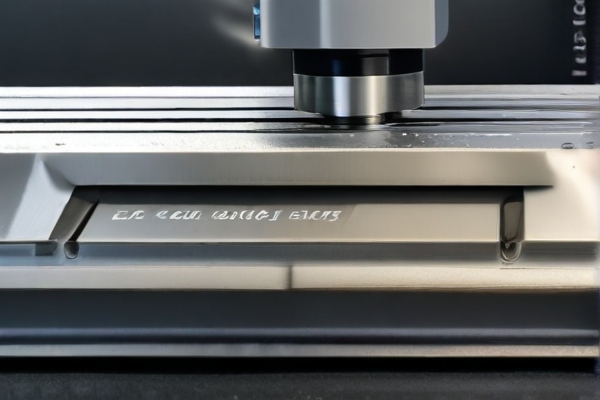

The router bits are crafted from tungsten carbide, known for its extreme hardness and resistance to wear. This material ensures the longevity of the cutting tools, maintaining sharpness over extended periods and enhancing cutting accuracy.

Their guiding rails and lead screws are made from hardened steel, which minimizes vibration and ensures smooth, precise movements. This plays a crucial role in achieving high precision in machining tasks.

Additionally, the servo motors are constructed with robust materials to offer consistent torque and speed. This precision contributes to the overall high performance and efficiency of the CNC routers, thus meeting diverse manufacturing needs.

The combination of these carefully selected materials allows SourcifyChina’s CNC routers to deliver top-notch performance. This makes it a trusted choice for professionals seeking efficiency, durability, and accuracy in their machining operations.

SourcifyChina’s top-rated CNC routers undergo rigorous quality control to ensure unmatched precision and durability. From raw material selection to final assembly, each stage is meticulously monitored to adhere to international standards. This dedication guarantees that only top-quality routers reach the market, offering customers reliable and efficient machinery.

The manufacturing process begins with sourcing premium raw materials, which undergo stringent testing to verify their compliance with quality specifications. Advanced machinery and experienced technicians are employed to fabricate components with the highest level of accuracy. This initial step is crucial to ensure the structural integrity of the CNC routers.

Subsequent phases involve detailed inspections and tests. Every component is examined using advanced quality control techniques, including 3D measuring tools and laser scanners. This ensures that all parts meet precise design and functional criteria. Assemblies are then conducted in controlled environments to mitigate any potential for contamination or error.

Final product testing is where SourcifyChina truly shines. Each CNC router is subjected to a series of functional and stress tests to ascertain operational readiness. This includes software calibrations, operational tests, and endurance run-throughs to confirm the reliability of each unit. Defective units are reworked or scrapped to maintain high-quality output.

Customer satisfaction is the cornerstone of SourcifyChina’s ethos. Post-manufacture, each CNC router is validated by independent third-party audits to guarantee compliance with global standards such as ISO and CE. Continuous feedback mechanisms are also in place to refine processes and integrate advanced technologies, ensuring that their CNC routers remain at the forefront of market innovation.

Overall, SourcifyChina’s commitment to quality control in their CNC router manufacturing process proves indispensable in delivering dependable, high-precision machinery that meets diverse industrial needs. This robust approach not only builds customer trust but also sets SourcifyChina as an industry leader in manufacturing excellence.

SourcifyChina’s top-rated CNC routers boast impressive precision and reliability. Their advanced engineering ensures every cut is clean and accurate, making them ideal for detailed projects demanding high levels of accuracy.

These routers excel in versatility, handling a wide array of materials such as wood, plastic, aluminum, and composite. This flexibility makes them perfect for various industries, from signage to furniture production.

On top of their flexibility, these machines come with user-friendly software. This software simplifies complex tasks, empowering users to execute intricate designs efficiently, even if they lack extensive technical expertise.

Durability is a significant strength of SourcifyChina’s CNC routers. Robust construction and high-quality components ensure long-term performance, minimizing downtime and maintaining productivity over extended periods.

Competitive pricing gives these routers additional appeal. They offer high-end features typically found in more expensive models, providing an excellent return on investment for businesses of all sizes.

Customer support from SourcifyChina is highly rated. They provide extensive resources, troubleshooting help, and prompt service to ensure customers maximize their machine’s capabilities.

These CNC routers also emphasize safety, incorporating advanced features like automatic shutoff and protective barriers. These measures ensure operators are protected while maximizing operational efficiency.

In summary, SourcifyChina’s top-rated CNC routers combine precision, versatility, user-friendly software, durability, competitive pricing, stellar customer support, and robust safety measures to offer an unparalleled solution for various manufacturing needs. Their comprehensive capabilities make them a valuable asset in any production environment, ensuring reliable, high-quality results.

Top-rated CNC routers offer unparalleled precision and versatility, making them invaluable tools for industries ranging from woodworking to metalworking and beyond.

– Precision and Accuracy: Top-rated CNC routers provide high levels of accuracy, ensuring every cut and engraving is flawless. This reduces material wastage and increases overall efficiency.

– Versatility: They can work on a variety of materials including wood, metal, plastic, and composites, making them suitable for diverse applications.

– Increased Productivity: Automation and faster processing speeds allow businesses to complete projects quicker, boosting productivity and turnaround times.

– Consistency: Once programmed, these machines produce consistent results every time, which is essential for large production runs.

– Customization: They allow for highly detailed and intricate designs, enabling more creative and customizable projects.

– Ease of Use: Modern CNC routers come with user-friendly interfaces, making them accessible even to operators with minimal technical knowledge.

– Cost-Effective: Precision reduces the need for rework, and automation cuts down labor costs, making these machines cost-effective in the long term.

– Durability: High-quality CNC routers are built to last, ensuring a reliable performance over many years without frequent maintenance.

– Scalability: They make scaling operations easier because they can handle increased workload without compromising on quality.

– Enhanced Safety: Automation minimizes the need for manual intervention, reducing the risk of workplace accidents.

In conclusion, investing in a top-rated CNC router can transform operations by enhancing precision, efficiency, and safety, providing a significant return on investment.

Top-rated CNC routers are renowned for their precision, versatility, and advanced features that enhance productivity and broaden the scope of creative possibilities.

Key Features:

– High Precision: Accurate cuts with minimal tolerances, ideal for intricate designs.

– Advanced Software Integration: Compatible with leading CAD/CAM software for seamless workflow.

– Robust Build Quality: Durable frames made from aluminum or steel for long-lasting use.

– High-Speed Spindles: Capable of reaching high RPMs for faster material removal and finishing.

– Versatile Material Compatibility: Can handle a variety of materials, from wood and plastics to metals.

– User-Friendly Interface: Intuitive controls and displays, often with touchscreens, for easy operation.

– Customizability: Options for upgrades and add-ons like tool changers and dust collection systems.

– Automated Features: Includes functions like tool path optimization and automated calibration to reduce manual work.

– Safety Features: Emergency stop buttons and protective guards to ensure operator safety.

– Efficient Cooling Systems: Keeps the router and spindle cool, extending their lifespan.

– Adjustable Cutting Speeds: Flexibility to adjust speeds based on material and project requirements.

– Large Working Area: Accommodates large sheets of material, reducing the need for multiple setups.

Advanced CNC routers combine these features to deliver unparalleled performance, making them essential tools for professionals in woodworking, metalworking, and various manufacturing industries.

SourcifyChina is a leading provider of top-rated CNC routers, acclaimed for their precision and efficiency. These advanced machines cater to various industries, including woodworking, metalworking, and plastics, enabling intricate and high-quality custom products.

The company’s CNC routers stand out for their unbeatable accuracy and repeatability, ensuring every project meets exact specifications. They are equipped with cutting-edge technology and robust build quality, making them ideal for both small-scale and large-scale manufacturing operations.

Furthermore, SourcifyChina offers tailored solutions, understanding that each business has unique requirements. Their team collaborates closely with clients to customize the routers, providing specialized software, tooling, and machinery adjustments to optimize performance.

Apart from machinery, SourcifyChina takes pride in the diversity of its custom products and projects. From furniture pieces and intricate carvings to precision-engineered parts and prototypes, the company’s CNC routers deliver exceptional results across a broad spectrum of applications.

The end-to-end service provided by SourcifyChina ensures that clients experience seamless integration of CNC routers into their production lines. This includes consultation, implementation, training, and ongoing support, guaranteeing that the machines operate at peak efficiency.

In summary, SourcifyChina’s top-rated CNC routers and custom solutions demonstrate the company’s commitment to quality, innovation, and customer satisfaction. These qualities make SourcifyChina an indispensable partner for businesses seeking to elevate their manufacturing capabilities.

SourcifyChina is a highly regarded company specializing in top-rated CNC routers, solidifying its position as a leader in the precision manufacturing industry. Known for its exceptional quality and innovative technology, SourcifyChina offers a diverse range of CNC routers that cater to various sectors, including woodworking, metalworking, and plastic fabrication. The company’s commitment to excellence is reflected in its rigorous quality control processes and continuous investment in research and development. Customers worldwide trust SourcifyChina for its reliable, high-performance machinery that enhances productivity and ensures precise results. By blending advanced engineering with customer-centric service, SourcifyChina not only meets but often exceeds industry standards, making it the go-to source for CNC routing solutions. Their dedication to maintaining a robust supply chain and providing excellent after-sales support further underscores their reputation as a top-tier provider in the CNC router market.

Top-rated CNC routers have revolutionized the Aerospace, Defense, and Marine industries by providing unparalleled precision and efficiency. In aerospace applications, these advanced machines are pivotal for the manufacturing of complex components used in aircraft and spacecraft. CNC routers enable the precise fabrication of lightweight yet durable materials such as aluminum, titanium, and composite materials, which are critical for high-performance aerodynamics and fuel efficiency. The ability to achieve tight tolerances ensures that parts fit together perfectly, reducing the likelihood of mechanical failure and enhancing the safety and reliability of aerospace vehicles. Additionally, top-rated CNC routers contribute to shorter production cycles, allowing for faster development of prototypes and quicker time-to-market for innovative aerospace technologies.

In the Defense sector, the accuracy and reliability of CNC routers are indispensable for producing intricate parts for military equipment, from weapons systems to armored vehicles and communication devices. These routers can handle a variety of materials, including metals and high-strength polymers, to produce components that meet stringent defense standards for durability and performance. For Marine applications, CNC routers are used to create critical parts for ships, submarines, and offshore platforms. The precision cutting capabilities ensure that components like propellers, hull sections, and mechanical systems are fabricated to exact specifications, enhancing the performance and longevity of marine vessels. By integrating top-rated CNC routers into their manufacturing processes, companies in the Aerospace, Defense, and Marine industries are able to achieve higher quality standards, improve operational efficiency, and maintain a competitive edge in their respective markets.

Top-rated CNC routers have revolutionized the automotive industry by significantly improving the precision and efficiency of manufacturing processes. In automotive applications, these advanced machines are used to create complex components such as engine parts, transmission systems, and custom body panels with unparalleled accuracy. CNC routers ensure that each part adheres to tight tolerances, which is crucial for the performance and safety of vehicles. These routers are capable of working with a variety of materials, including metals, plastics, and composites, allowing manufacturers to utilize the best-suited materials for each application. The incorporation of CNC technology reduces the risk of human error, speeds up production times, and lowers costs, driving innovation and competitiveness within the automotive sector.

In the electronics industry, top-rated CNC routers are pivotal in the production of intricate and precise components essential for modern devices. These routers are instrumental in fabricating printed circuit boards (PCBs), enclosures, and heat sinks, which are critical for the functionality and durability of electronic gadgets. CNC routers enable the miniaturization of electronic components by allowing high-precision cutting and drilling, essential for the dense packing of circuits required in today’s compact devices. The routers’ ability to handle delicate materials such as silicon wafers and various polymers ensures that components meet the stringent quality standards demanded by the industry. As a result, CNC routers not only enhance manufacturing efficiency but also contribute to the reliability and performance of consumer electronics, medical devices, and other high-tech products.

Top-rated CNC (Computer Numerical Control) routers are revolutionizing the construction industry by enhancing precision, efficiency, and versatility. In construction, these routers are primarily employed for cutting, drilling, and milling various materials such as wood, metal, and composite panels. Utilizing advanced software, CNC routers can execute complex designs and patterns with utmost accuracy, ensuring that components fit together perfectly. This level of precision minimizes material waste and significantly reduces the time required for manual adjustments. Architects and builders appreciate CNC routers for their ability to create intricate architectural details, custom moldings, and bespoke furniture pieces, thereby adding both aesthetic appeal and structural integrity to modern constructions.

In the energy sector, top-rated CNC routers play a critical role in the fabrication of components used in renewable energy systems and traditional power plants. For instance, they are instrumental in manufacturing high-precision parts for wind turbines, such as rotor blades and aerodynamic nacelles. CNC routers are also utilized in the production of solar panel frames, mounting structures, and inverter housings, necessitating high levels of accuracy and consistency to ensure optimal performance. By enabling the mass production of complex and precise parts quickly and efficiently, CNC routers help in the rapid deployment of energy solutions, ultimately aiding in the transition to renewable energy sources. Furthermore, energy sector companies benefit from reduced production costs and enhanced product quality, thanks to the automation and precision offered by these advanced machining tools.

The industrial equipment industry has undergone a significant transformation with the integration of top-rated CNC routers, bringing precision, efficiency, and versatility to the manufacturing process. CNC (Computer Numerical Control) routers are instrumental in automating tasks such as cutting, milling, and engraving on a variety of materials, including metals, plastics, wood, and composites. These high-precision machines are programmable to execute complex designs and intricate details that would be challenging and time-consuming to achieve manually. Industries such as automotive, aerospace, and electronics benefit from the accuracy and repeatability of CNC routers, resulting in higher quality products and reduced wastage. Their ability to handle diverse production requirements makes CNC routers indispensable in streamlining operations, enhancing productivity, and driving industrial innovation.

Moreover, the adaptability of top-rated CNC routers allows manufacturers to respond quickly to market demands and customization requests. This flexibility is paramount in sectors where product differentiation and time-to-market are critical. For instance, in the aerospace industry, the need for lightweight, precisely engineered components is addressed efficiently with CNC routers, which can produce complex geometries with tight tolerances. Similarly, the electronics sector relies on these routers to produce detailed circuit boards and components essential for modern devices. The integration of advanced software into CNC routers further simplifies the transition from design to production, offering seamless prototyping and iterative development. Hence, by leveraging top-rated CNC routers, the industrial equipment industry not only enhances its operational capabilities but also fosters an environment of innovation and competitiveness.

CNC routers, renowned for their precision and versatility, have become indispensable in the medical device industry. These top-rated machines enable the production of highly intricate and accurate components essential for modern medical devices. From orthopedic implants to dental prosthetics, CNC routers ensure that each part meets the stringent standards required for medical applications. The precision of CNC routers allows for the customization of devices tailored to individual patient needs, enhancing the effectiveness of medical treatments and improving patient outcomes. Moreover, the ability to work with various materials, including metals, plastics, and composites, makes CNC routers a versatile tool in fabricating a wide range of medical components.

In addition to manufacturing implants and prosthetics, CNC routers play a crucial role in the production of surgical instruments and diagnostic equipment. These devices must adhere to exacting specifications to ensure reliability and safety during medical procedures. CNC routers excel in creating complex geometries and fine tolerances, which are vital for the functionality of surgical tools and devices. The automation and precision of CNC routing also contribute to reducing production time and costs, making advanced medical devices more accessible. Consequently, the integration of top-rated CNC routers in the medical device industry not only enhances the quality and precision of medical products but also supports innovation and efficiency in healthcare technology.

Modern machining and manufacturing processes have significantly evolved with the integration of top-rated CNC (Computer Numerical Control) routers. These advanced machines bring unparalleled precision, efficiency, and versatility to a wide range of industries. CNC routers are highly regarded for their ability to automate the cutting, carving, drilling, and milling processes on various materials such as wood, plastic, metal, and composites. This automation not only enhances the consistency and accuracy of the produced parts but also drastically reduces the time and labor required. Top-rated CNC routers are equipped with sophisticated software that translates intricate designs into precise, repeatable movements, enabling manufacturers to achieve complex geometries and intricate details that would be almost impossible with manual machining techniques.

In manufacturing applications, top-rated CNC routers are pivotal in both small-scale operations and large-scale production lines. They are extensively used in industries such as aerospace, automotive, furniture, and electronics, where precision and efficiency are paramount. For example, in the aerospace sector, CNC routers are employed to create lightweight and complex components from high-strength materials, ensuring both safety and performance. In the furniture industry, these routers allow for the mass production of intricate designs with stunning accuracy, contributing to both aesthetic appeal and structural integrity. Additionally, top-rated CNC routers often incorporate advanced features like multi-axis machining, automatic tool changers, and real-time monitoring systems, which further optimize production workflows and minimize downtime. The adoption of these state-of-the-art machines has propelled manufacturers toward greater innovation, higher quality, and enhanced competitiveness in the global market.

Sure! Here is a list of frequently asked questions (FAQ) about manufacturing top-rated CNC routers and quality work from SourcifyChina factory:

Q: What makes SourcifyChina’s CNC routers top-rated?

A: SourcifyChina’s CNC routers are top-rated due to their precision engineering, durable materials, advanced technology, and rigorous quality control processes. The factory uses high-grade components and state-of-the-art machinery to ensure superior performance and longevity.

Q: How does SourcifyChina ensure the quality of their CNC routers?

A: Quality is ensured through stringent quality control measures, including thorough testing at various stages of production. The factory adheres to international standards and certifications, and employs experienced engineers to oversee the manufacturing process.

Q: Can SourcifyChina customize CNC routers to specific requirements?

A: Yes, SourcifyChina offers customization options to meet specific requirements. Clients can specify dimensions, power configurations, and add-on features. The engineering team works closely with clients to design CNC routers tailored to individual needs.

Q: What is the typical lead time for manufacturing and delivering CNC routers?

A: The typical lead time varies depending on the complexity of the order and production schedule. Generally, it ranges from 4 to 8 weeks from order confirmation to delivery. For detailed timelines, please contact their sales team.

Q: Does SourcifyChina provide after-sales support and service?

A: Yes, SourcifyChina provides comprehensive after-sales support, including installation guidance, operator training, maintenance services, and technical support. They ensure that clients can smoothly integrate their CNC routers into their production processes.

Q: Are the CNC routers energy-efficient?

A: Absolutely. SourcifyChina designs their CNC routers with energy efficiency in mind, incorporating features that minimize power consumption without compromising performance. This helps reduce operational costs and environmental impact.

Q: What industries can benefit from SourcifyChina’s CNC routers?

A: SourcifyChina’s CNC routers are versatile and can be used in various industries including aerospace, automotive, woodworking, metal fabrication, signage, and more. Their precision and durability make them suitable for a wide range of applications.

Q: How do I place an order with SourcifyChina?

A: To place an order, you can contact SourcifyChina through their website, email, or phone. Their sales team will assist you with the order process, customization options, and provide quotations based on your requirements.

When seeking top-rated CNC routers from SourcifyChina Factory, it’s crucial to prioritize certain aspects to ensure optimal performance and value. Here are some tips to guide your selection:

1. Manufacturer Reputation: SourcifyChina is known for connecting buyers with reliable manufacturers. Check for customer reviews, industry certifications, and any available case studies to validate the factory’s credibility.

2. Product Specifications: Ensure the CNC routers meet your specific requirements. Key parameters include spindle power, working area dimensions, machine weight, maximum speed, and software compatibility.

3. Quality Control: Verify SourcifyChina’s quality control processes. Look for ISO certifications or similar standards that confirm stringent quality checks are in place.

4. Customization Options: Engage with manufacturers offering customization to meet unique operational needs. This may include special spindle types, advanced cooling systems, or specific software integrations.

5. Technical Support: Robust post-sale support is vital. Evaluate the manufacturer’s customer service, availability of spare parts, and the provision of technical manuals and online support.

6. Cost and Value: While cost is important, it shouldn’t compromise quality. SourcifyChina Factory often provides competitive pricing without sacrificing quality. Request detailed quotations and compare them to industry benchmarks.

7. Lead Times and Logistics: Confirm production lead times and shipping logistics. Reliable factories should provide clear timelines and efficient shipping options to your location.

8. Sample Orders: If feasible, request sample orders to test machine performance firsthand before committing to larger purchases. This minimizes risk and ensures the product meets your standards.

9. Industry Recognition: Factories recognized by industry bodies or those that participate in prominent trade shows often signify credibility and innovation.

By prioritizing these factors, you can confidently source high-quality CNC routers from the SourcifyChina Factory, ensuring efficiency and reliability in your operations.

Sure, here are some FAQ excerpts for sourcing top-rated CNC routers from the SourcifyChina factory:

1. What types of CNC routers does SourcifyChina factory offer?

SourcifyChina factory offers a variety of CNC routers including 3-axis, 4-axis, and 5-axis machines, catering to different industrial needs such as wood carving, metal cutting, and plastic molding.

2. How can I determine the right CNC router for my needs?

To choose the right CNC router, consider the materials you will be working with, the complexity of the designs, and the production volume. SourcifyChina’s expert team can also provide personalized recommendations based on your specific requirements.

3. Is it possible to get a sample before placing a bulk order?

Yes, SourcifyChina factory offers sample units so you can evaluate the quality and performance of the CNC routers before making a bulk purchase.

4. What is the lead time for a standard order of CNC routers from SourcifyChina?

The typical lead time for a standard order is around 4-6 weeks, but this can vary depending on the order quantity and customization requirements.

5. Do the CNC routers come with any warranty?

Yes, all CNC routers from SourcifyChina factory come with a standard 1-year warranty covering manufacturing defects and certain parts. Extended warranty options are also available.

6. Does SourcifyChina offer technical support and training?

SourcifyChina provides comprehensive technical support, including online troubleshooting and on-site technician services. Training sessions can be arranged to ensure your team can efficiently operate the CNC routers.

7. What are the payment terms available?

SourcifyChina offers flexible payment terms, including T/T (Telegraphic Transfer), L/C (Letter of Credit), and secure online payment gateways to facilitate smooth transactions.

8. Can I customize my CNC router order?

Yes, SourcifyChina allows for various customizations such as spindle power, working table size, and additional attachments to suit specific operational needs.

9. How does SourcifyChina ensure product quality?

SourcifyChina employs rigorous quality control processes including material inspection, precision calibration tests, and final performance checks to ensure that every CNC router meets high-quality standards.

10. What shipping options are available?

Sourcing top-rated CNC routers from a manufacturer in China, such as SourcifyChina, can be streamlined through these tips:

1. Research Thoroughly:

– Online Reviews and Ratings: Use platforms like Alibaba, Made-in-China, and Global Sources to read customer reviews and ratings.

– References and Case Studies: Request references or case studies from potential suppliers to verify their quality and reliability.

2. Assess Manufacturer Credentials:

– Certifications: Look for ISO, CE, and other quality certifications.

– Factory Audits: Conduct audits if possible, or request virtual tours. SourcifyChina may facilitate factory audits to ensure compliance with standards.

3. Compare Specifications and Price:

– Evaluate the CNC routers based on technical specifications relevant to your needs (e.g., precision, bed size, motor power).

– Obtain quotes from multiple suppliers to compare costs without compromising on quality.

4. Communicate Clearly:

– Detailed Requirements: Provide detailed specifications and use cases to the supplier to ensure they understand your needs.

– Language and Clarity: Use clear, concise language, and consider employing a translator if necessary.

5. Request Samples:

– Prioritize suppliers willing to provide samples. This helps in assessing the build quality and performance before bulk purchases.

6. Negotiate and Finalize Terms:

– Payment Terms: Negotiate favorable payment terms, ideally with a portion held until receipt and inspection of goods.

– Shipping and Delivery: Confirm logistics, including shipping time and costs, and ensure the supplier handles customs documentation.

7. Utilize Sourcing Services:

– SourcifyChina: They offer resources to connect you with reliable CNC router manufacturers. Leverage their expertise to find top-rated products efficiently.

By combining thorough research, clear communication, and leveraging sourcing services, you can effectively source high-quality CNC routers from reputable Chinese manufacturers.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.