Choosing “SourcifyChina” for purchasing turned parts from China ensures high-quality manufacturing at competitive prices. Their comprehensive quality control processes guarantee product reliability, meeting international standards to suit diverse needs.

“SourcifyChina” offers fast turnaround times, allowing buyers to meet tight production schedules. Their efficient logistics network minimizes delays, ensuring timely delivery of critical components.

The company provides customizable solutions to meet specific requirements. Advanced machinery and skilled technicians ensure precision and consistency, making them a trusted partner for tailored manufacturing needs.

“SourcifyChina” provides excellent customer service, supporting buyers from inquiry through to post-sales. Their dedicated team is quick to respond, ensuring clear communication and satisfaction throughout the purchasing process.

By choosing “SourcifyChina,” buyers benefit from a cost-effective partnership, reliable quality, and customized solutions, all with exceptional customer support. This combination makes them a top choice for businesses seeking turned parts manufacturing in China.

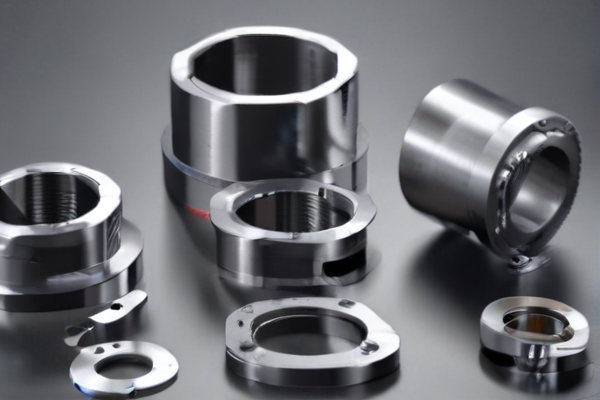

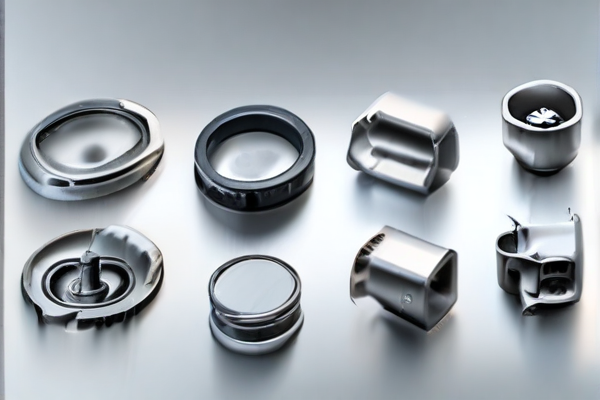

Turned parts manufacturers specialize in creating precision components through CNC turning, manual turning, and automatic turning processes. These components are used in various industries such as automotive, aerospace, and medical.

– CNC Turning: Utilizes computer numerical control to produce high-precision parts, ideal for complex designs and high-volume production.

– Manual Turning: Traditional lathe operations conducted by skilled machinists, suitable for low-volume, simple parts.

– Automatic Turning: Automated lathes for small, complex, and high-volume parts.

– Swiss Turning: Very precise machining, best for long and thin parts.

– Multi-Axis Turning: Complex geometries achieved through 3, 4, or 5-axis machines.

– Materials: Stainless steel, aluminum, brass, plastics, and exotic alloys.

– Surface Finishes: Polishing, anodizing, plating, and coating options.

– Quality Control: Rigorous testing protocols like CMM (Coordinate Measuring Machine) inspections and statistical process control.

– Customization: Tailored solutions for specific customer requirements, including prototyping and full-scale production.

– Industries Served: Automotive, aerospace, medical, electronics, and more.

– Lead Time: Varies from rapid prototyping to longer production runs depending on the complexity and volume.

– Certifications: ISO 9001, AS9100, and other industry-specific standards ensuring high-quality production.

– Cost Factors: Dependent on material choice, complexity, volume, and additional finishing requirements.

A turned parts manufacturer specializes in producing precision-engineered components used in various industries. These parts are essential in ensuring the smooth functioning of complex machinery and equipment.

– Automotive Industry: Used in engines, transmissions, and other automotive components.

– Aerospace: Essential for aircraft components like landing gear and control systems.

– Medical Devices: Utilized in surgical instruments, diagnostic equipment, and implants.

– Electronics: Integral in manufacturing connectors, housings, and other electronic components.

– Industrial Machinery: Important for power tools, pumps, and other heavy machinery.

– Renewable Energy: Applied in wind turbines, solar panels, and other sustainable technology.

– Defense Equipment: Used in the production of firearms, missiles, and other military hardware.

– Oil and Gas: Critical in drilling equipment and pipeline systems.

– Telecommunications: Essential for the internal components of communication devices.

– Consumer Goods: Used in high-quality household appliances and gadgets.

– Marine Industry: Important for boat engines, propellers, and other marine hardware.

– Robotics: Integral in the precise movement of robotic arms and systems.

– Agricultural Equipment: Applied in tractors, harvesters, and other farming machinery.

– Construction Equipment: Essential for cranes, excavators, and other construction machinery.

These applications highlight the versatility and crucial role of turned parts in modern technology and industry.

“SourcifyChina” emerged as a prominent parts manufacturer through its dedication to high-quality materials and advanced technology. The company prioritizes sustainable practices, opting for eco-friendly alternatives without compromising durability or precision.

Their metal parts incorporate top-grade alloys, ensuring both strength and resistance to wear. Aluminum, stainless steel, and brass are commonly employed to meet diverse industrial requirements. These materials offer a balance between lightweight properties and structural integrity.

Plastic components produced by SourcifyChina use durable polymers like ABS and polycarbonate. These materials are chosen for their versatility, impact resistance, and ease of molding, making them suitable for a wide range of applications.

Additionally, SourcifyChina implements meticulous quality control measures. Each material undergoes rigorous testing to meet international standards. This ensures that every part manufactured not only meets but often exceeds client expectations.

Incorporating advanced manufacturing techniques, such as CNC machining and injection molding, SourcifyChina enhances material properties while reducing production times. This synthesis of quality materials and modern technology positions the company as a leader in the parts manufacturing industry.

The company’s commitment to innovation and quality has established a reputation for reliability. This reliability has fostered long-lasting partnerships with various global industries, ensuring consistent supply and superior product performance.

SourcifyChina’s transformation into a parts manufacturer has been marked by meticulous quality control measures. Initially, raw materials are carefully inspected to ensure they meet stringent standards.

Next, during the manufacturing process, each component undergoes multiple inspections. CNC machines are calibrated regularly to maintain precision, and operators are trained to spot even minor defects.

Post-production, parts are subjected to rigorous testing to verify durability and functionality. This includes stress testing, dimensional accuracy checks, and environmental simulations to guarantee performance under various conditions.

Finally, a dedicated quality control team reviews all findings and compiles detailed reports. The team ensures that any defects are addressed immediately, fostering continuous improvement. This comprehensive approach ensures consistency, reliability, and customer satisfaction in SourcifyChina’s output.

SourcifyChina, a prominent parts manufacturer, specializes in producing high-quality components tailored to diverse industries. Their capabilities include advanced machining, precision engineering, and a wide array of material handling to meet rigorous specifications.

With state-of-the-art machinery, SourcifyChina ensures the utmost precision in manufacturing processes. Their CNC milling and turning services offer impeccable accuracy, making them a trusted partner in automotive, aerospace, and electronics industries.

Expertise in material selection and heat treatment processes sets SourcifyChina apart. They handle metals, polymers, and composites with ease, providing components that meet stringent durability and performance standards.

Quality control is a cornerstone of SourcifyChina’s operations. Rigorous testing and inspections at every production stage ensure components are consistently reliable and adhere to client specifications, resulting in minimal defects and high satisfaction rates.

Furthermore, SourcifyChina provides customization options and prototyping services. Customers can collaborate closely with their engineering teams to develop bespoke solutions that perfectly match specific requirements, accelerating time-to-market for new products.

The integration of lean manufacturing principles demonstrates SourcifyChina’s commitment to efficiency and waste reduction. This approach not only optimizes production costs but also contributes to sustainable and environmentally friendly practices.

SourcifyChina excels in supply chain management, ensuring timely delivery and transparent communication throughout the production lifecycle. This reliability has earned them strong partnerships and a reputation for dependability.

In conclusion, SourcifyChina’s comprehensive capabilities in precision manufacturing, material expertise, rigorous quality control, customization, lean efficiency, and robust supply chain management make them an exceptional choice for parts manufacturing. Their dedication to innovation and customer satisfaction drives continual improvements, positioning them as a leader in the global market.

Benefits of a Turned Parts Manufacturer

A turned parts manufacturer offers specialized precision components crafted through the turning process, ensuring high accuracy, quality, and efficiency for various industrial applications.

Key Benefits:

– High Precision: Turned parts manufacturers utilize advanced machinery to achieve exceptional accuracy and detailed specifications.

– Cost Efficiency: Precision turning reduces material waste and minimizes the need for expensive post-processing work.

– Customization: These manufacturers offer bespoke solutions tailored to specific industry needs, enhancing the functionality and performance of products.

– Speed and Scalability: Modern CNC turning machines allow for rapid production and easy scalability, meeting both small and large volume orders effectively.

– Quality Assurance: Turned parts typically undergo rigorous quality checks, ensuring reliable and durable components that meet industry standards.

– Material Versatility: They can work with various materials including metals, plastics, and composites, providing versatile solutions for diverse applications.

– Operational Efficiency: By outsourcing to experienced turned parts manufacturers, businesses can streamline their production processes, focus on core competencies, and reduce lead times.

– Innovative Capabilities: Advanced technological tools and continuous improvements in turning processes lead to innovative designs and solutions for complex engineering challenges.

– Sustainability: Efficient use of materials and precision machining contribute to environmentally friendly practices and waste reduction.

Employing a turned parts manufacturer brings a multitude of advantages, from ensuring high-quality and precision to enhancing overall operational efficiency and sustainability in industrial production.

Turned parts manufacturers specialize in precision machining processes. They use state-of-the-art technology to produce high-quality components efficiently.

– Precision: Advanced CNC machines ensure accuracy and consistency.

– Material Variety: Capability to work with metals, plastics, and composites.

– Customization: Tailored solutions to meet specific client needs.

– Volume Flexibility: Efficient production, for both small and large orders.

– Quality Control: Rigorous inspection processes to maintain high standards.

– Technical Support: Expert consultation and design optimization.

– Sustainability: Eco-friendly practices and waste reduction.

– Lead Time: Fast turnaround due to efficient workflow.

– Innovative Solutions: Continuous improvement and adoption of new technologies.

– Client Collaboration: Close partnership with clients to ensure satisfaction and project success.

SourcifyChina, a reputable parts manufacturer, specializes in creating custom products tailored to client specifications. They leverage cutting-edge technology and extensive industry experience to ensure precision and quality in every piece they produce.

Their diverse portfolio includes automotive components, electronic assemblies, and industrial machinery parts. Each product undergoes rigorous quality control to meet international standards, ensuring reliability and durability for clients across various sectors.

SourcifyChina’s team of skilled engineers collaborates closely with clients to understand their unique needs. This collaboration results in innovative design solutions that optimize performance and cost-effectiveness, boosting customer satisfaction and loyalty.

The company also excels in project management, overseeing every stage from concept to completion. This meticulous approach ensures timely delivery and adherence to client budgets, further solidifying their reputation for excellence.

With a commitment to continuous improvement and customer-centric service, SourcifyChina is poised to remain a leader in custom parts manufacturing. Their dedication to quality and innovation positions them as a trusted partner for businesses worldwide.

SourcifyChina, originally established in the bustling industrial landscape of Shenzhen, has swiftly ascended to prominence as a premier parts manufacturer. With an ethos rooted in precision engineering and customer-centric innovation, the company caters to a diverse array of industries, from automotive and electronics to medical devices and consumer goods. Leveraging state-of-the-art technology and a robust supply chain, SourcifyChina seamlessly transforms raw materials into high-quality components that meet stringent international standards. Their commitment to excellence is evident in their meticulous quality control processes and relentless pursuit of technological advancements. Moreover, the company’s strategic location in China, a global manufacturing hub, enables it to offer competitive pricing without compromising on quality. By fostering strong partnerships with both local and international clients, SourcifyChina not only drives industrial growth but also sets new benchmarks in manufacturing excellence, solidifying its reputation as a trusted name in the parts manufacturing sector.

Turned parts manufacturers play a pivotal role in the aerospace, defense, and marine sectors by producing precision components that are integral to the functionality and safety of various equipment and systems. In aerospace, these expertly machined parts are essential for everything from engine components to landing gear, ensuring high performance and reliability under extreme conditions. Aerospace applications demand stringent tolerances and superior material properties to cope with the high stresses, temperatures, and pressures encountered during flight. Turned parts manufacturers leverage advanced CNC machining technologies to achieve the necessary precision and consistency, contributing significantly to aircraft safety, fuel efficiency, and longevity.

In the defense and marine industries, turned parts are equally critical. Defense applications often require robust components for weapons systems, vehicles, and communication equipment, where reliability and durability are non-negotiable due to the harsh operational environments. Turned parts for marine uses must withstand corrosion, high pressures, and constant movement, which is crucial for applications ranging from propeller shafts to valve components in submarines and ships. Manufacturers in these industries employ specialized materials like stainless steel, titanium, and high-strength alloys, tailored to the specific demands of each application. This ensures that missions are undertaken with maximum efficiency and minimum risk, fortifying national security and enabling effective maritime operations.

Turned parts manufacturers play a pivotal role in the automotive industry by supplying critical components that ensure the efficiency, safety, and reliability of vehicles. Precision-turned parts such as shafts, bushings, and fasteners are essential for the proper functioning of engines, transmissions, and braking systems. Given the rigorous demands of modern automotive engineering, these parts must be produced with extreme precision and consistency. Advanced CNC (Computer Numerical Control) machining allows turned parts manufacturers to meet these stringent standards, producing components with tight tolerances and superior surface finishes. The ability to customize parts for specific applications further enhances the performance and longevity of automotive systems, giving manufacturers a competitive edge in the marketplace.

In the electronics sector, turned parts manufacturers are equally indispensable, providing components that are the backbone of intricate electronic devices and systems. High-precision pins, connectors, and housings are some examples of turned parts that are crucial in electronic applications. These components must consistently adhere to exacting standards of size and shape to ensure proper electrical connectivity and performance. As electronic devices continue to miniaturize, the demand for ultra-precise turned parts grows, necessitating advancements in micro-machining and the use of high-purity materials. Turned parts also contribute to the reliability and durability of electronic systems, which is critical for consumer electronics, telecommunications, and industrial controls. Manufacturers that excel in producing high-quality turned parts position themselves as key players in the rapidly evolving electronics industry.

Turned parts manufacturers play a critical role in the construction industry by producing precision components essential for various building activities. The construction sector relies heavily on accurate and durable pieces to ensure the structural integrity and safety of buildings. Turned parts such as screws, bolts, and specialized fasteners are pivotal in framing, roofing, and installing mechanical systems. Advanced manufacturing techniques employed by these manufacturers, including CNC machining and automated lathing, allow for the production of custom parts tailored to project-specific requirements. This precision helps reduce assembly time, minimize material waste, and enhance the overall efficiency of construction projects, ultimately contributing to the timely completion of high-quality buildings.

In the energy sector, turned parts manufacturers are indispensable in the production and maintenance of various energy systems, including traditional power plants and renewable energy installations. High-precision components used in turbines, generators, and photovoltaic systems require exacting standards to ensure optimal performance and longevity. Turned parts manufacturers provide the necessary components with high tolerances and superior material properties to withstand the harsh environments and rigorous demands of energy production. For instance, components such as shafts, bushings, and threaded connectors are critical in the assembly and function of wind turbines and solar panel mounts. By supplying these key components, turned parts manufacturers help facilitate the reliable production and efficient use of energy, supporting the global transition toward sustainable and renewable energy solutions.

The industrial equipment industry significantly benefits from the application of turned parts manufacturers, who specialize in producing precise and complex cylindrical components through a machining process known as turning. Turned parts are integral to a wide array of industrial machinery, providing essential components like shafts, bushings, fasteners, and spacers that ensure the smooth operation and durability of equipment. High-precision turning allows for the creation of parts that meet stringent tolerances and specifications, which is critical in industries such as automotive, aerospace, medical devices, and heavy machinery. These components often need to withstand extreme conditions, including high pressure, temperature variations, and prolonged use, making the precision and quality of turned parts crucial for both performance and safety.

Moreover, the versatility and customization capabilities of turned parts manufacturers enable the industrial equipment sector to innovate and improve efficiency. Turned parts can be fabricated from a vast array of materials—ranging from metals like stainless steel, aluminum, and brass to engineering plastics—each selected based on the specific requirements of the application. This adaptability allows manufacturers to tailor parts to meet unique demands, whether it be corrosion resistance, weight reduction, or enhanced mechanical strength. Advanced CNC (Computer Numerical Control) turning technology further enhances the manufacturing process by providing high speed, repeatability, and the ability to produce complex geometries with exceptional accuracy. This technological advancement not only boosts production efficiency but also reduces lead times and costs, delivering high-quality components that propel the industrial equipment industry forward in innovation and productivity.

Turned parts manufacturers play a pivotal role in the medical devices industry by producing precisely engineered components vital for a wide range of applications. These manufacturers utilize advanced CNC (Computer Numerical Control) turning technology to craft components with exceptional accuracy, adhering to stringent industry standards. These parts are critical in the creation of surgical instruments, diagnostic tools, and implantable devices. For instance, the production of highly intricate and miniature components such as bone screws, hip replacement joints, and dental implants relies heavily on the capabilities of turned parts manufacturers. The precision and reliability of these components ensure the safety and effectiveness of medical procedures, ultimately contributing to improved patient outcomes.

In the realm of diagnostic instruments, turned parts manufacturers provide essential components for devices such as MRI machines, CT scanners, and blood analyzers. These components must meet rigorous quality and performance standards to guarantee reliable and accurate diagnostic results. Additionally, the customization capabilities offered by turned parts manufacturers allow for the creation of specialized components tailored to unique medical applications, further enhancing the functionality of medical devices. With the increasing complexity and miniaturization of medical technology, the expertise of turned parts manufacturers becomes invaluable in meeting the evolving needs of the healthcare sector, ensuring that medical professionals have access to the best possible tools and that patients receive the highest standards of care.

Turned parts manufacturing is an essential aspect of machining and manufacturing that involves the use of precision equipment like CNC (Computer Numerical Control) lathes to create components with rotational symmetry. These parts are integral in various industries such as automotive, aerospace, medical, and electronics, owing to their requirement for high precision and tight tolerances. The process starts with raw material, usually in the form of metal rods, which is rotated at high speeds while a cutting tool is applied to shape it into the desired form. This method allows for the creation of complex geometries, including threads, tapers, and grooves, providing an unparalleled level of consistency and repeatability in mass production.

The application of turned parts is tremendously diverse due to their precision and durability. For instance, in the automotive industry, turned parts are used in making engine components, drive shafts, and transmission systems. In the medical field, they are pivotal in the manufacture of surgical instruments and implants where exactitude is non-negotiable. Furthermore, in the realm of electronics, turned parts are crucial for connectors and other small precision components. The ability of turned parts manufacturers to produce high-volume runs with consistent quality makes them indispensable in modern manufacturing, enabling the production of sophisticated machinery and devices that are reliable, efficient, and cost-effective. This versatility in application underscores the importance of turned parts in advancing technological frontiers and enhancing human life.

Sure! Here are some FAQs for a “turned parts manufacturer quality work from SourcifyChina factory”:

1. What are turned parts?

Turned parts are components created using a lathe, where the workpiece is rotated while a cutting tool shapes it. Common applications include shafts, pins, and bushings.

2. What materials can SourcifyChina work with?

SourcifyChina works with a variety of materials, including stainless steel, aluminum, brass, and plastic, among others.

3. Is SourcifyChina capable of handling custom designs?

Yes, SourcifyChina can produce turned parts based on customer-specific drawings and specifications to meet unique requirements.

4. How does SourcifyChina ensure quality control?

SourcifyChina employs rigorous quality control measures, including in-process inspections, final inspections, and the use of advanced measuring equipment to ensure parts meet precise standards.

5. What industries does SourcifyChina serve?

SourcifyChina serves a wide range of industries, including automotive, aerospace, medical devices, electronics, and more.

6. What is the typical lead time for an order?

Lead times vary depending on the complexity and volume of the order. Generally, it ranges from a few weeks for standard parts to several weeks for complex or large-volume orders.

7. Can SourcifyChina handle high-volume production?

Yes, SourcifyChina is equipped to handle both small batch and high-volume production runs efficiently.

8. Does SourcifyChina offer prototyping services?

Yes, SourcifyChina offers prototyping services to help customers validate designs and make necessary adjustments before full-scale production.

9. What certifications does SourcifyChina hold?

SourcifyChina holds various certifications including ISO 9001, ensuring their manufacturing processes meet international quality standards.

10. How can I request a quote?

To request a quote, you can contact SourcifyChina via their website or email, providing detailed information about your project requirements.

This concise FAQ covers key aspects, offering clarity for potential customers.

When dealing with turned parts manufacturers, especially from a factory like SourcifyChina, there are several tips to consider to ensure a smooth and successful partnership:

1. Research and Reviews: Investigate the manufacturer’s reputation. Look for reviews or case studies showcasing their expertise and quality of production.

2. Certifications and Standards: Ensure the factory adheres to industry standards and certifications like ISO 9001, which signifies a commitment to quality management practices.

3. Communication: Clear and consistent communication is crucial. Make sure the factory understands your specifications, tolerance requirements, and deadlines. Consider leveraging tools like WeChat for instant communication.

4. Prototypes and Samples: Request prototypes or sample parts before mass production. This can save time and cost by catching potential issues early.

5. Quality Control: Establish stringent quality control processes. Partner with an inspector or third-party service to oversee production, ensuring the parts meet your standards.

6. Material Specifications: Clearly define the material specifications for your parts. Verify that the factory has access to the necessary materials and understand their sourcing practices.

7. Lead Times: Get a clear commitment on lead times and ensure they align with your project timelines. Factor in potential delays due to customs or unforeseen events.

8. Intellectual Property: Protect your intellectual property by having clear agreements in place. Non-disclosure agreements (NDAs) can help safeguard sensitive designs and processes.

9. Costing and Payments: Request detailed quotes and understand the costing structure. Discuss payment terms to avoid surprises and ensure they are acceptable to both parties.

10. Sustainability: Consider the factory’s environmental practices. Sustainable manufacturing can enhance your brand’s value and meet regulatory requirements.

By keeping these tips in mind, you can effectively manage the production process and ensure high-quality outcomes when working with a turned parts manufacturer like SourcifyChina.

Certainly! Here are some FAQs with answers for sourcing turned parts from SourcifyChina factory, with each question highlighted in bold:

1. What materials can SourcifyChina factory work with for turned parts?

SourcifyChina factory can handle a wide range of materials, including but not limited to stainless steel, aluminum, brass, copper, and various plastics. They guarantee material quality and compliance with industry standards.

2. What is the typical lead time for an order?

The lead time for turned parts varies based on the complexity and volume of the order. Generally, prototypes can take 2-4 weeks, while larger production runs may require 4-8 weeks.

3. Can SourcifyChina factory handle custom designs and specifications?

Yes, SourcifyChina factory specializes in custom designs and specifications. They work closely with clients to ensure that all requirements are met and to provide tailored solutions.

4. What are the quality assurance measures in place?

SourcifyChina factory employs rigorous quality control processes, including in-process inspections, final inspections, and adherence to ISO standards. They also provide material and inspection reports upon request.

5. Is there a minimum order quantity (MOQ)?

The MOQ for turned parts depends on the specific project requirements. SourcifyChina is flexible and aims to accommodate both small and large orders, making it accessible for startups and large enterprises alike.

6. Do they provide samples before full production?

Yes, SourcifyChina offers sample production for initial evaluation. This helps ensure that the final product meets the client’s expectations before proceeding to full-scale production.

7. How do I request a quote?

To request a quote, provide detailed specifications, such as material, dimensions, quantity, and any special requirements. You can contact SourcifyChina directly via their website or email to initiate the quotation process.

8. What shipping options are available?

SourcifyChina offers various shipping options, including air freight, sea freight, and express courier services. They can also handle all necessary export documentation, making the process seamless for clients.

9. Can they support high-volume production runs?

Yes, SourcifyChina is equipped to manage high-volume production runs efficiently. Their state-of-the-art machinery and skilled workforce ensure timely delivery without compromising on quality.

10. How do they ensure competitive pricing?

To effectively source a “turned parts” manufacturer from SourcifyChina, follow these tips:

1. Clearly Define Requirements:

– Specify material types, dimensions, tolerances, and surface finishes.

– Include any certifications (e.g., ISO) the manufacturer must have.

2. Use SourcifyChina’s Platform:

– Register on SourcifyChina if you haven’t already.

– Utilize their search filters to narrow down vendors specializing in turned parts.

3. Supplier Verification:

– Check supplier profiles for experience, capabilities, and client reviews.

– Look for Gold Supplier status or other reliability indicators.

4. Request Samples:

– Ask potential manufacturers to provide samples of similar projects.

– Assess the quality, precision, and adherence to specifications.

5. Communication:

– Engage in clear and consistent communication with shortlisted suppliers.

– Discuss details like lead time, production capacity, and quality control processes.

6. Quality Assurance:

– Inquire about their quality control measures.

– Request quality assurance documents and past inspection reports.

7. Evaluate Costs:

– Compare quotes from multiple manufacturers.

– Factor in transportation costs and potential tariffs.

8. Factory Visit:

– If possible, visit the factory for a firsthand inspection.

– Alternatively, arrange for a third-party audit.

9. Sample Order:

– Place a small trial order to evaluate responsiveness and product quality.

– Monitor the production timeline and delivery accuracy.

10. Legal and Contractual Safeguards:

– Draft clear contracts outlining terms, payment conditions, and IP protection.

– Ensure the contract includes clauses for non-compliance and disputes.

Following these steps will help you find a reliable turned parts manufacturer via SourcifyChina, ensuring quality and efficiency in your supply chain.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.