“Reliable SourcifyChina: Transforming Factory Operations as a Leading Parts Manufacturer in China”

If you are looking for a comprehensive article about SourcifyChina’s evolution into a premier parts manufacturer, this would certainly fit the mold, ensuring both clarity and SEO efficiency.

Choosing SourcifyChina for buying turning parts from China offers competitive pricing without compromising quality. They rigorously manage production processes ensuring consistent precision. SourcifyChina has a vast network of vetted, reputable manufacturers, ensuring reliability and timely delivery. Their comprehensive service includes quality control inspections, logistics management, and robust after-sales support.

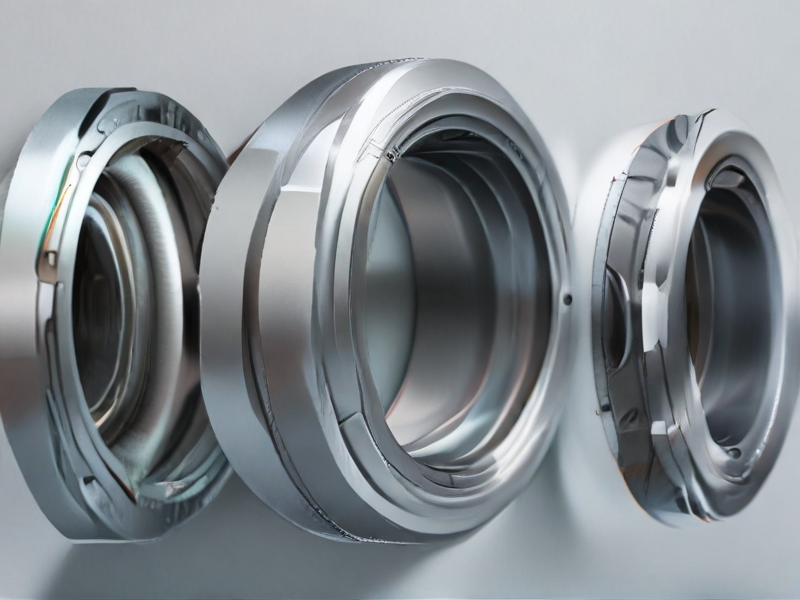

Turning parts manufacturers use various machining processes to produce precision components from metal, plastic, and other materials. Key considerations include production volume, material selection, and complexity. Options range from small-scale shops to large facilities specializing in high-precision, high-volume production. Here are some types and options available:

– Small-scale shops: Ideal for custom, low-volume orders; offer personalized services.

– Medium-sized manufacturers: Balance between volume and customization; capable of handling varied production needs.

– Large-scale facilities: High-volume production with advanced technologies; focus on efficiency and consistency.

– CNC machining: Utilizes computer-controlled tools for highly precise and repeatable parts.

– Manual turning: Skilled machinists operate manual lathes for specialized, intricate work.

– Automated turning centers: Equipped with multiple spindles and tools, designed for high efficiency.

– Prototype services: Fast turnaround for design validation and testing.

– Quick-turn services: Expedited production for urgent orders.

– Multi-axis turning: Produces complex parts by moving the workpiece and tool on multiple axes.

– Materials: Specialization in different materials like steel, aluminum, brass, plastics, and composites.

– Quality control: Advanced inspection techniques like CMM (Coordinate Measuring Machine) and optical inspection for ensuring dimensional accuracy.

– Finishing services: Offer additional processes such as anodizing, plating, and heat treatment.

– Industry-specific expertise: Manufacturers often specialize in sectors like aerospace, automotive, medical, and electronics.

Each turning parts manufacturer offers distinct advantages based on their specialization, capabilities, and services, allowing customers to select the best fit for their specific requirements.

Turning parts manufacturers are essential in creating precision components used across various industries. Their expertise ensures high-quality production of intricate parts for numerous applications, enhancing functionality and performance.

– Automotive Industry: Manufacturing engine components, transmission parts, and other critical car parts.

– Aerospace Industry: Producing precise parts required for aircraft engines, landing gear, and avionics.

– Medical Devices: Creating complex components for surgical instruments, implants, and diagnostic equipment.

– Electronics: Making small, delicate parts integral to circuit boards and electronic devices.

– Industrial Machinery: Crafting durable parts for heavy machinery, ensuring efficiency and longevity.

– Energy Sector: Supplying components for turbines, oil and gas extraction equipment, and renewable energy systems.

– Agriculture: Producing parts for farming equipment and machinery.

– Defense: Delivering high-precision parts for military equipment and weaponry.

– Consumer Products: Manufacturing components for appliances, tools, and other household items.

– Custom Engineering: Providing bespoke solutions tailored to specific client requirements and innovative projects.

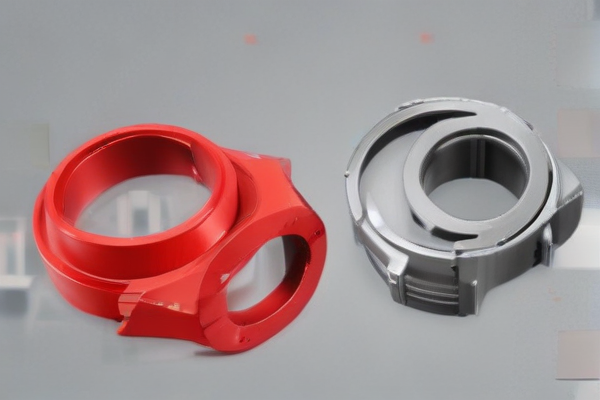

SourcifyChina is committed to delivering high-quality materials for turning parts manufacturing. Their materials include stainless steel, aluminum, brass, and titanium. Each material is sourced from reputable suppliers to ensure durability and reliability in finished products.

Stainless steel is a favored choice due to its corrosion resistance and strength, making it suitable for industrial applications. Aluminum is lightweight and offers excellent machinability, ideal for automotive and aerospace industries. Brass is preferred for its excellent thermal conductivity and machinability, often used in electrical components and fittings.

Titanium is renowned for its high strength-to-weight ratio and corrosion resistance, critical for aerospace, medical, and high-performance engineering. SourcifyChina’s rigorous quality control processes ensure that all materials conform to industry standards, providing clients with consistent and dependable products.

The company prides itself on its customer-centric approach, offering customized material solutions tailored to specific client needs. By keeping a robust inventory and maintaining strong partnerships with suppliers, SourcifyChina can quickly respond to client demands, ensuring timely delivery of materials.

SourcifyChina’s commitment to sustainability sets them apart in the industry. They prioritize eco-friendly sourcing and manufacturing practices to minimize environmental impact. By combining quality materials with ethical practices, SourcifyChina continues to lead as a trusted partner in the turning parts manufacturing industry. With an unwavering focus on quality, innovation, and customer satisfaction, they are poised for significant future growth.

SourcifyChina boasts a rigorous quality control process for its turning parts manufacturing. Each step, from raw material selection to final inspection, is meticulously monitored to ensure only top-quality components reach the client. Advanced machinery and precision tools are employed to maintain high production standards.

The company utilizes state-of-the-art software and hardware to monitor and control each phase of production. This integration of technology ensures that measurements are precise and each part meets specified tolerances. Real-time tracking and adjustments help to reduce errors and optimize efficiency.

Operators are highly trained professionals with specialized skills in quality assurance practices. Regular training sessions ensure staff are up-to-date with the latest industry standards and technological advancements. This level of expertise contributes significantly to maintaining quality and mitigating defects in the products.

Additionally, SourcifyChina implements a multi-phase inspection process. Initial on-the-line checks are followed by thorough audits in the quality control lab. Each turning part undergoes stress tests, durability evaluations, and dimensional inspections to assure it meets critical quality benchmarks.

Customer feedback plays a crucial role in SourcifyChina’s quality control strategy. Feedback loops are established to continually integrate client suggestions and industry trends. This proactive approach helps in fine-tuning manufacturing processes and elevating product quality to exceed customer expectations.

In sum, SourcifyChina’s comprehensive quality control process ensures a high level of precision and reliability in its turning parts. By combining advanced technology, skilled workforce, and rigorous inspection protocols, they consistently deliver components that meet and often exceed industry standards. This dedication to excellence is what solidifies their reputation as a trusted parts manufacturer.

SourcifyChina is a premier parts manufacturer offering top-notch precision machining services. Specializing in CNC machining, they produce high-quality metallic and plastic components suited for various industries, including automotive, aerospace, and electronics.

The company excels in rapid prototyping, enabling clients to bring innovative products to market quickly. Their advanced 3D printing technologies and experienced engineers ensure accurate, functional prototypes that meet stringent quality standards.

In addition to machining and prototyping, SourcifyChina provides robust die-casting and injection molding services. Their state-of-the-art facilities guarantee efficient large-scale production runs, delivering consistent, high-quality components at competitive prices.

Commitment to quality is a hallmark of SourcifyChina. Utilizing rigorous quality control processes, they adhere to international standards like ISO 9001 and ISO/TS 16949, ensuring defect-free products and heightened customer satisfaction.

Their adept engineering team collaborates closely with clients, offering bespoke design and material selection advice. This partnership fosters innovation and helps reduce production costs while maintaining product integrity.

With a customer-centric approach, SourcifyChina offers comprehensive supply chain management. They handle every stage from material sourcing to final delivery, ensuring seamless and timely project execution. Robust logistics and inventory management systems minimize lead times and optimize production schedules.

Environmental responsibility is a core value at SourcifyChina. They implement eco-friendly practices in their manufacturing processes, including energy-efficient machinery and sustainable materials. This commitment aligns with global sustainability goals, reducing their carbon footprint.

In summary, SourcifyChina is a versatile parts manufacturer with unparalleled expertise in precision machining, rapid prototyping, and large-scale production. Their commitment to quality, innovation, customer satisfaction, and sustainability positions them as a reliable partner for diverse manufacturing needs.

Turning parts manufacturers offer numerous advantages, boosting efficiency and productivity across various industries.

– Precision and Accuracy: Advanced CNC turning machines ensure high levels of precision and consistency in parts, reducing errors and enhancing quality.

– Cost-Effectiveness: Automated processes lower labor costs and minimize material waste, resulting in overall cost savings.

– Scalability: Easily scalable to meet varying production demands, from small batches to large volumes.

– Customizability: Capabilities to produce custom parts tailored to specific needs and specifications.

– Quick Turnaround: Efficient processes and technologies enable faster production times and quicker delivery to market.

– Durability: Produces long-lasting, robust components that improve the lifespan and reliability of end products.

– Versatility: Suitable for a wide range of materials, including metals, plastics, and composites, making it adaptable to diverse applications.

– Innovation: Continuous technological advancements provide cutting-edge solutions and improvements in manufacturing processes.

– Quality Control: Rigorous testing and quality assurance protocols ensure that every part meets stringent industry standards.

– Sustainability: Reduced material waste and energy-efficient machinery contribute to more sustainable manufacturing practices.

A turning parts manufacturer specializes in creating precision components through a subtractive machining process called turning, which is essential for various industries.

Key Features:

– Precision: High-accuracy machining to meet exact specifications.

– Material Variety: Ability to work with metals, plastics, and composites.

– Quality Control: Rigorous inspection processes to ensure product consistency.

– Customization: Tailored solutions to meet unique client requirements.

– Advanced Technology: Utilization of CNC machines and CAD/CAM software.

– Scalability: Capability to handle both small and large production runs.

– Expertise: Skilled workforce with extensive industry experience.

– Prototyping Services: Fast turnaround for prototypes and small batches.

– Sustainability: Environment-friendly practices and waste management.

– Customer Support: Comprehensive pre-sale and post-sale assistance.

These features enable turning parts manufacturers to provide high-quality, reliable components for diverse applications across various sectors.

SourcifyChina has established itself as a leading parts manufacturer, specializing in custom products and projects. Expert in sourcing and production, they ensure quality and cost-effective solutions tailored to clients’ unique requirements.

Their extensive network of suppliers allows for quick turnarounds and access to a wide range of materials. This versatility makes them a go-to for businesses looking to streamline their supply chains efficiently.

SourcifyChina also places immense emphasis on innovation and adaptability. By staying current with technological advances, they deliver cutting-edge solutions that help companies stay competitive in a fast-paced market.

Customer satisfaction is at the heart of SourcifyChina’s operation. From initial consultation through to product delivery, their customer-centric approach ensures consistent communication and adherence to project timelines.

Their adept team of engineers and specialists offers unparalleled expertise, guiding clients through complex projects. This ensures precision, durability, and performance in every product manufactured.

In addition to custom manufacturing, SourcifyChina excels in project management. They oversee every stage of production, minimizing risks and ensuring timely completion, thus boosting client confidence and satisfaction.

Ultimately, SourcifyChina is committed to fostering long-term partnerships by delivering high-quality, custom products that meet and exceed client expectations. They are a reliable partner for any company seeking bespoke manufacturing solutions.

SourcifyChina is a dynamic and innovative parts manufacturing company rooted in the heart of China’s thriving industrial sector. The company specializes in providing high-quality components across a broad spectrum of industries, including automotive, electronics, and machinery. SourcifyChina leverages cutting-edge technology and state-of-the-art production facilities to deliver exceptional manufacturing solutions tailored to meet the unique needs of its global clientele. By prioritizing stringent quality control measures and sustainable manufacturing practices, the company ensures that every part produced not only meets but often exceeds international standards. With a team of highly skilled engineers and a steadfast commitment to customer satisfaction, SourcifyChina is rapidly emerging as a trusted partner for businesses seeking reliable, cost-effective, and innovative parts manufacturing services. The company’s dedication to continuous improvement and its proactive approach to addressing the evolving demands of the global market position it as a leader in the industry, driving growth and fostering strong, long-term client relationships.

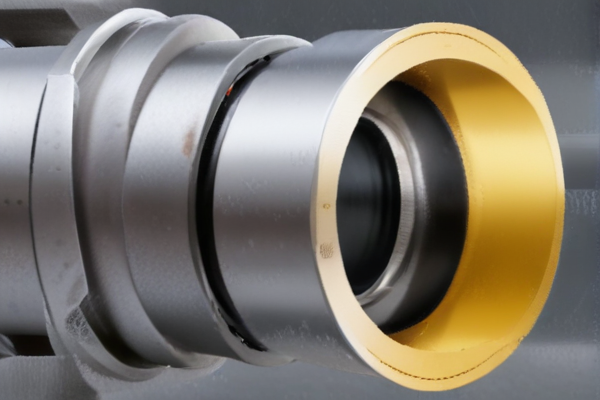

The aerospace, defense, and marine industries demand extremely high precision and reliability in their components, given the critical nature of their applications. Turning parts manufacturers play a vital role in these sectors by producing intricately machined components that meet strict tolerances and quality standards. In aerospace, for instance, manufacturers supply parts like turbine blades, engine components, and hydraulic system parts that must endure extreme temperatures and pressures while maintaining structural integrity. The defense sector benefits from these manufacturers by sourcing parts for military vehicles, weapon systems, and communication devices that require robust and fail-safe performance. Precision-turned parts are integral to ensuring that these high-stakes applications function seamlessly and safely under various challenging conditions.

Similarly, the marine industry relies heavily on turning parts manufacturers for producing critical components used in shipbuilding, offshore platforms, and undersea exploration equipment. Marine applications often involve exposure to harsh environments, including saltwater corrosion, high pressure, and extreme temperatures. Manufacturers produce parts such as propeller shafts, valve components, and navigation system parts that are engineered to withstand these strenuous conditions while providing long-term durability and reliability. The precision machining and rigorous quality control processes employed in turning parts manufacturing are essential to achieve the exacting standards required, ensuring that vessels and marine infrastructure operate efficiently and safely. In essence, the expertise of turning parts manufacturers is indispensable across aerospace, defense, and marine industries for maintaining operational excellence and driving innovation forward.

Turning parts manufacturers play a crucial role in the automotive industry by producing high-precision components essential for vehicle performance and safety. These manufacturers utilize advanced turning processes, including CNC (Computer Numerical Control) machining, to create parts like axles, drive shafts, gear components, and engine parts. The rigorous requirements of the automotive sector demand highly accurate and reliable components, as even the smallest imperfection can lead to significant performance issues or safety risks. Turning parts manufacturers meet these demands by utilizing state-of-the-art technology and quality control systems, ensuring that each part adheres to strict industry standards and specifications. Their contributions support innovations in vehicle design, fuel efficiency, and emission control, driving continuous improvements across the automotive landscape.

In the realm of electronics, turning parts manufacturers provide essential components for devices ranging from consumer electronics to industrial automation systems. Precision is paramount in electronics applications, where miniature components like connectors, fasteners, and heat sinks must meet exacting tolerances to ensure optimal functionality. Advanced machining techniques allow manufacturers to produce parts with extreme precision and fine surface finishes, critical for the performance and durability of electronic devices. The demand for compact yet powerful electronic devices drives the need for increasingly sophisticated and miniaturized components, pushing turning parts manufacturers to continuously innovate. Their expertise supports the development of cutting-edge technologies, such as smartphones, wearable devices, and advanced computing systems, making them indispensable partners in the ever-evolving electronics industry.

Turning parts manufacturers play a crucial role in the construction industry by supplying precision-machined components essential for various building and infrastructure projects. These components, often made from durable materials such as steel, aluminum, and plastics, are integral in the assembly of machinery, structural frameworks, and safety systems. For example, custom-turned parts are used in the construction of cranes, elevators, and HVAC systems, ensuring that these machines operate smoothly and reliably. The precision and quality of these parts directly impact the structural integrity and safety of the buildings and infrastructure, highlighting the manufacturers’ contribution to robust construction practices. Additionally, advanced CNC turning technology enables the production of complex geometries and tight tolerances, meeting the specific requirements of modern construction challenges.

In the energy sector, turning parts manufacturers are indispensable in producing precision components for equipment used in power generation, oil and gas exploration, and renewable energy systems. Turbine engines, pump systems, and drilling equipment all rely heavily on custom-turned parts, which must withstand extreme pressures, temperatures, and corrosive environments. For instance, turbine blades in power plants require meticulously machined profiles to optimize airflow and efficiency, achieved through advanced turning processes. Similarly, in the renewable energy domain, components for wind and solar energy systems depend on precision turning to ensure optimal performance and longevity. By delivering high-quality, reliable parts, turning parts manufacturers contribute significantly to the efficiency and sustainability of energy production, supporting the ongoing global transition towards cleaner energy sources.

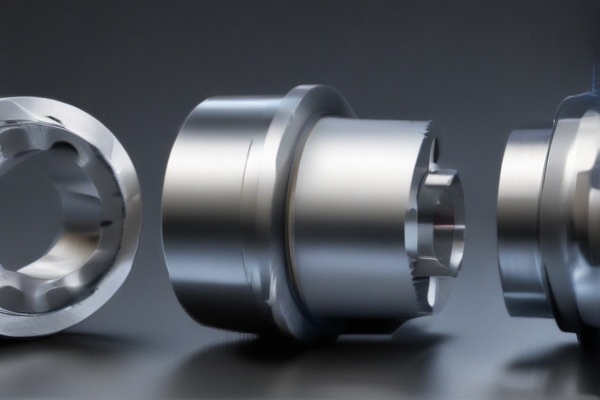

The industrial equipment industry heavily relies on precision machined components, and turning parts manufacturers play a crucial role in this ecosystem. These manufacturers specialize in producing cylindrical parts with high levels of accuracy and tight tolerances, both of which are essential for the efficiency and reliability of industrial machinery. Turning parts, which are created using advanced CNC lathes, include shafts, bushings, and spindles that are integral to the operation of pumps, motors, and other mechanical systems. The precision and quality provided by turning parts manufacturers ensure that these industrial components can withstand rigorous operational demands and provide consistent performance, minimizing downtime and maintenance costs for end-users.

In addition to enhancing the durability and functionality of industrial equipment, turning parts manufacturers also contribute to innovation and customization within the industry. As various segments of the industrial equipment market demand specialized machinery tailored to specific operational needs, the ability to produce customized turning parts becomes invaluable. These manufacturers often work closely with equipment designers and engineers to develop bespoke solutions that meet unique structural and functional requirements. The use of sophisticated materials and state-of-the-art machining technologies allows for the creation of components that can handle extreme conditions, such as high temperatures, pressure, and corrosive environments. This level of customization and precision fosters the development of advanced industrial equipment that can drive efficiency, productivity, and technological progress across a wide range of sectors, from manufacturing and energy to aerospace and healthcare.

The field of medical devices heavily relies on the precision and reliability offered by turning parts manufacturers. These manufacturers specialize in creating intricately designed components that are vital for the optimal functioning of various medical instruments and devices. Whether it’s for surgical tools, diagnostic equipment, or life-support systems, the accuracy of turned parts is non-negotiable. Advanced CNC turning processes ensure that each component meets stringent industry standards, boasting micron-level precision which is indispensable for applications where a minor deviation can have significant repercussions on patient outcomes.

Additionally, turning parts manufacturers are instrumental in the development of custom medical solutions. With the rise of personalized medicine and bespoke medical instruments tailored to individual patient needs, the ability to produce small batches of highly specialized parts is essential. Manufacturers offer flexibility in material choices, such as stainless steel, titanium, and biocompatible plastics, all of which are crucial for ensuring durability and patient safety. By leveraging sophisticated software and state-of-the-art machinery, these manufacturers are able to iterate rapidly, enhancing innovation without compromising on quality. Consequently, the application of precision-turned parts in medical devices not only elevates the efficacy of clinical treatments but also paves the way for groundbreaking advancements in medical technology.

Turning parts manufacturers play a crucial role in the machining and manufacturing industries, providing precision components essential for a myriad of applications. These manufacturers specialize in turning, a subtractive machining process where a cutting tool removes material from a rotating workpiece to create parts with precise dimensions and smooth finishes. The versatility of turning operations allows for the production of various components, ranging from simple cylindrical shapes to highly complex geometries. Manufacturers utilize advanced CNC (Computer Numerical Control) turning machines, which offer high precision, repeatability, and efficiency. This enables them to meet the stringent tolerances and specifications required in sectors like aerospace, automotive, medical devices, and robotics. CNC machines also facilitate batch production, making it possible to produce large quantities of identical parts with consistent quality.

In the realm of manufacturing, turning parts manufacturers contribute to the development of both standard and tailored components. These components include shafts, bushings, bolts, and custom fittings that are fundamental to the assembly and operation of machinery. By offering custom machining solutions, these manufacturers can address the unique requirements of different industries. The ability to rapidly prototype and produce custom parts enables companies to bring new products to market faster, enhancing their competitive edge. Moreover, turning parts manufacturers often provide secondary services such as threading, knurling, and drilling to add additional features to the turned parts. This comprehensive approach not only enhances the functionality of the components but also streamlines the supply chain, reducing the need for multiple vendors and improving overall production efficiency. Through precision machining and value-added services, turning parts manufacturers empower industries to innovate and maintain high standards of quality and performance.

What services does SourcifyChina offer for turning parts manufacturing?

SourcifyChina specializes in producing high-quality turning parts tailored to meet specific requirements. Our services include precision turning, threading, boring, and finishing, all executed with state-of-the-art CNC machinery for optimal accuracy and consistency.

How does SourcifyChina ensure the quality of turning parts?

We implement a rigorous quality control process at every production stage. This includes material inspection, in-process monitoring, and final product testing using advanced measurement tools and techniques. Our ISO-certification further underscores our commitment to quality.

Can SourcifyChina manufacture custom turning parts?

Yes, SourcifyChina excels in producing custom turning parts according to client specifications. We work closely with clients to understand their unique needs and deliver bespoke solutions that meet exacting standards.

What materials can SourcifyChina work with for turning parts?

We work with a diverse range of materials, including various grades of stainless steel, aluminum, brass, and plastics. Should you have specific material requirements, we can source and process them to suit your application.

What industries does SourcifyChina serve?

We serve a broad spectrum of industries, including automotive, aerospace, medical devices, electronics, and heavy machinery. Our versatile manufacturing capabilities allow us to cater to distinct industry needs with precision.

How can I request a quote for turning parts?

You can request a quote by visiting our website and filling out the inquiry form, or by directly contacting our sales team. Provide as much detail as possible regarding your requirements—drawings, specifications, materials, and quantities—to ensure an accurate and timely quote.

What is SourcifyChina’s turnaround time for manufacturing turning parts?

Turnaround times vary based on the complexity and volume of the order. Typically, we provide lead times during the quoting process. However, we strive to accommodate urgent requests without compromising quality.

Does SourcifyChina offer international shipping?

Yes, we ship products worldwide. We collaborate with reliable logistics partners to ensure timely and safe delivery of your turning parts, providing tracking and support throughout the shipping process.

When seeking a reliable turning parts manufacturer, SourcifyChina factory stands out as a viable option. Here are some tips to enhance your manufacturing experience with them:

1. Research and Compare: Investigate SourcifyChina’s capabilities, compare them with other manufacturers, and focus on their expertise in turning parts.

2. Quality Assurance: Prioritize manufacturers with ISO certification or other quality management systems to ensure high standards. Verify their quality control processes.

3. Prototyping: Use their prototyping services to evaluate the precision and quality of their turning parts before committing to large-scale production.

4. Material Selection: Clearly communicate your material requirements. SourcifyChina typically offers various materials like aluminum, steel, and brass.

5. Technical Specifications: Provide detailed technical drawings and specifications. Ensure there’s a mutual understanding to avoid miscommunication.

6. Sample Orders: Start with small batch orders to test the reliability and quality of the turning parts while assessing their supply chain capabilities.

7. Lead Time: Confirm lead times and factor in shipping durations. SourcifyChina may offer faster turnarounds given their large-scale production capabilities.

8. Cost Efficiency: While aiming for competitive pricing, don’t compromise on quality. SourcifyChina usually offers a good balance of cost and quality.

9. Communication: Maintain clear and consistent communication. Use platforms like emails, video conferences, or messaging apps to stay updated.

10. Inspection and Testing: Request in-line inspections and final testing reports to ensure the parts meet your standards before shipping.

11. Logistics: Leverage their experience with international shipping and customs regulations to streamline the logistics process.

12. Feedback Loop: Provide feedback on their services and parts to foster continuous improvement.

By focusing on these tips, you can ensure a smoother and more efficient partnership with SourcifyChina for your turning parts manufacturing needs.

Sure, here is an FAQ list for sourcing turning parts manufacturers from SourcifyChina factory, with each question bolded:

Q: What types of turning parts does SourcifyChina factory manufacture?

A: SourcifyChina manufactures a wide range of turning parts including custom CNC machined components, metal precision parts, and complex industrial parts made from various materials like aluminum, stainless steel, brass, and more.

Q: How can I get a quote for turning parts from SourcifyChina?

A: You can obtain a quote by submitting a request through their website. Provide detailed specifications, quantity, material, and any special requirements to receive an accurate quote.

Q: What is the lead time for orders from SourcifyChina?

A: The lead time typically depends on the complexity and quantity of the order. Standard lead times range from 2 to 6 weeks. For precise timelines, it’s best to consult directly with SourcifyChina.

Q: What quality control measures does SourcifyChina have in place?

A: SourcifyChina utilizes stringent quality control processes, including in-process inspections, final inspections, and use of advanced measuring equipment to ensure high precision and quality in all their turning parts.

Q: Can SourcifyChina handle custom designs and prototypes?

A: Yes, SourcifyChina is equipped to manage custom designs and create prototypes. They offer design assistance and rapid prototyping services to meet clients’ specific needs.

Q: What are the payment terms for sourcing from SourcifyChina?

A: Payment terms usually include a deposit upon order confirmation and the balance prior to shipment. Specific terms can be negotiated directly with SourcifyChina based on order size and client requirements.

Q: Does SourcifyChina provide shipping and logistics support?

A: Yes, SourcifyChina offers comprehensive shipping and logistics support, including international shipping arrangements. They can handle all documentation and customs clearance to ensure timely delivery.

Q: Are there any minimum order quantity (MOQ) requirements?

A: The MOQ may vary depending on the specific parts and project scope. Generally, SourcifyChina does have MOQ requirements which can be discussed during the quotation process.

Q: How can I verify the credibility of SourcifyChina as a supplier?

A: To verify credibility, you can request references, review client testimonials, and check for certifications such as ISO standards. You can also arrange a factory visit if feasible.

Sourcing a “turning parts manufacturer from SourcifyChina factory” involves some strategic steps to ensure you find reliable and high-quality partners. Here are some tips:

1. Define Your Requirements: Clearly outline the specifications, materials, quantity, and quality standards of the turning parts you need. This helps in communicating effectively with potential manufacturers.

2. Initial Search on SourcifyChina: Use precise keywords related to your needs such as “turning parts manufacturer” or “custom turning parts.” Utilize filters to narrow down by industry, capability, and certification.

3. Assess Manufacturer Profiles: Review the listed manufacturers’ profiles for details like years of experience, customer reviews, past projects, and certifications (ISO, CE, etc.).

4. Request Samples: Ask for samples or prototypes to verify the quality before moving forward. Assess the precision, material quality, and durability of the parts.

5. Verify Credentials: Conduct due diligence by requesting copies of certificates and checking third-party reviews. Reliable manufacturers will have recognizable certifications and positive feedback from other clients.

6. Communicate Clearly: Initiate communication by explaining your project requirements and expectations. Clear and detailed communication can reveal their responsiveness and technical understanding.

7. Evaluate Facility Capabilities: If possible, arrange a visit to the manufacturer’s facility through a virtual tour or an in-person visit. This helps in assessing their machinery, production capacity, and quality control processes.

8. Negotiate Terms: Discuss pricing, payment terms, lead times, and shipping arrangements. Ensure that there is a mutual understanding and agreement on all terms.

9. Contract Agreement: Draft a detailed contract that includes all agreed terms, production schedules, quality standards, and penalties for non-compliance.

10. Pilot Production: Start with a pilot production run to manage any unforeseen issues before full-scale manufacturing. This helps in fine-tuning the process and ensuring consistency in quality.

By following these steps, you will increase your chances of finding a reliable turning parts manufacturer through SourcifyChina, ensuring high-quality production and smooth operations.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.