## Reliable SourcifyChina Factory: What Is a CNC Machinist?

Understanding the Role of a CNC Machinist in the Precision Engineering Sector of SourcifyChina Factory

In today’s manufacturing landscape, precision and efficiency are paramount. SourcifyChina Factory exemplifies this ethos, and at its core—ensuring quality in every produced part—are its CNC machinists. But what exactly does a CNC machinist do?

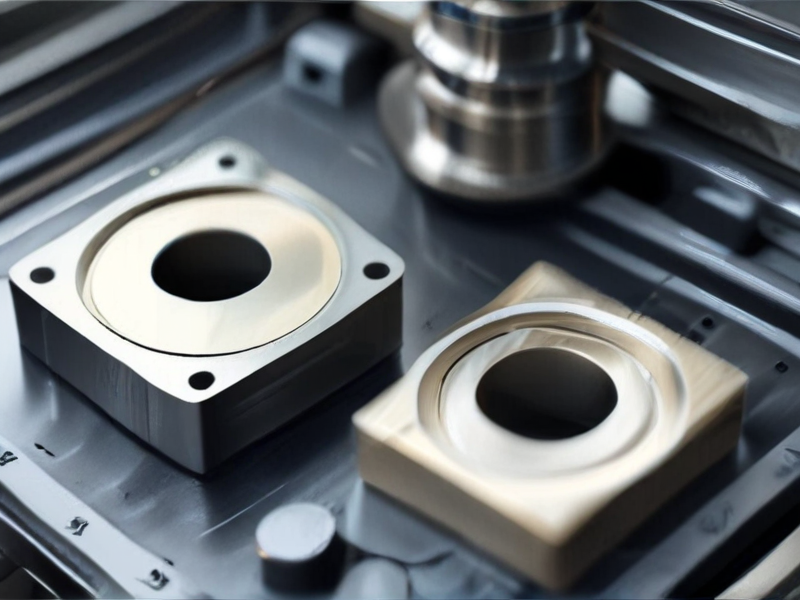

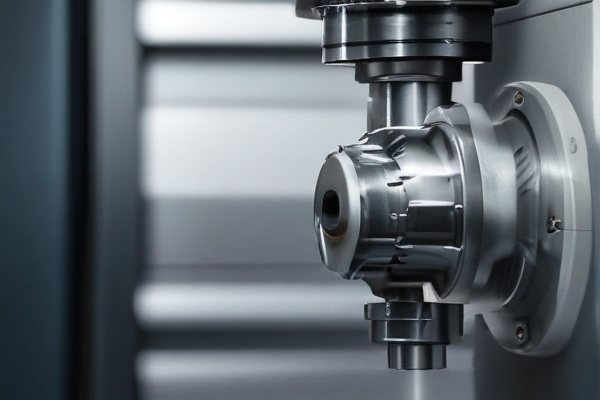

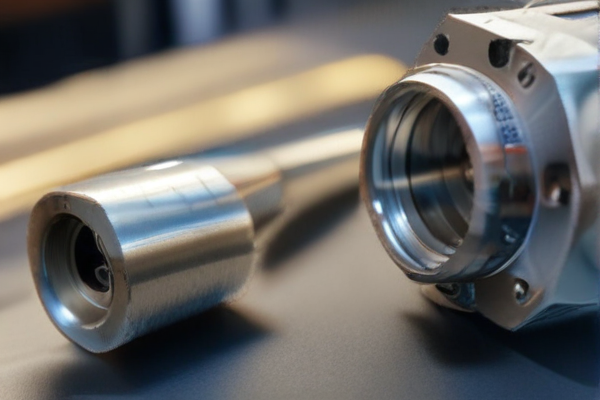

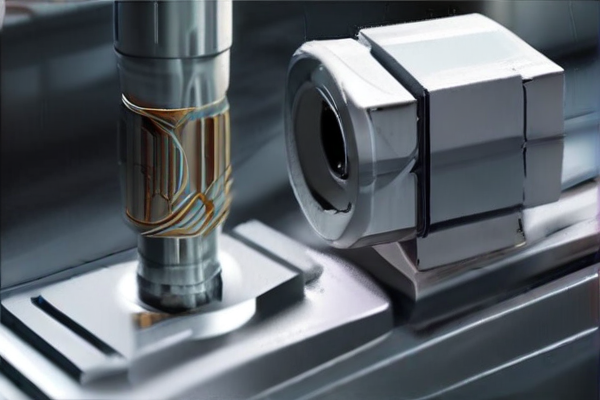

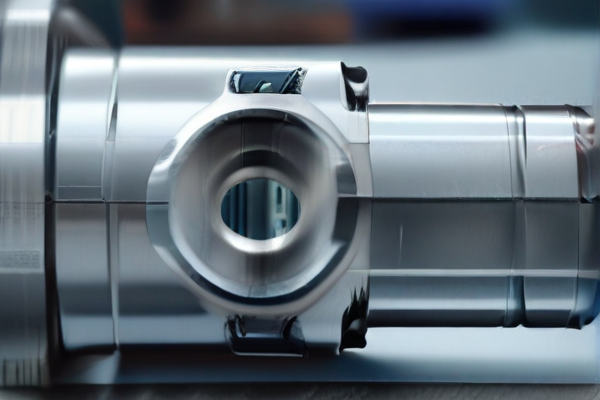

A CNC (Computer Numerical Control) machinist is a skilled professional who operates sophisticated machinery that cuts, grinds, drills, or shapes materials into high-precision parts and products. Using computer-controlled tools and software, CNC machinists follow blueprints and specifications to produce intricate designs with unparalleled accuracy.

At SourcifyChina Factory, CNC machinists are not just operators but artisans of mechanical engineering. Their expertise ensures that the machinery runs efficiently, the products meet rigorous standards, and any deviations are corrected swiftly. From fabricating components for aerospace to creating bespoke industrial parts, the CNC machinist’s role is indispensable.

Moreover, training and continuous learning are pivotal for CNC machinists at SourcifyChina Factory. With rapid technological advancements, these machinists stay updated on the latest techniques and tools, ensuring that they can handle both traditional materials and cutting-edge composites with the same level of proficiency.

In summary, SourcifyChina Factory’s reliable excellence stems from the dedication and precision of its CNC machinists. Their role transcends mere operation, embodying a blend of technical skill and craftsmanship that guarantees top-notch production standards.

Choosing SourcifyChina Factory provides buyers with high-quality products at competitive prices, leveraging advanced CNC machining technologies. This ensures precision, durability, and adherence to international standards, satisfying even the most discerning clients.

SourcifyChina Factory employs skilled CNC machinists, who are experts in computer numerical control machines. These professionals ensure intricate designs and complex parts are produced accurately, enhancing product reliability and performance.

Additionally, the factory offers exceptional customer service. They maintain transparent communication and timely deliveries, ensuring that buyers receive their orders as expected. This builds lasting relationships and trust in their services.

In conclusion, SourcifyChina Factory stands out due to its advanced technology, skilled workforce, and commitment to customer satisfaction. Choosing them means access to reliable, precise products and professional support throughout the purchasing process.

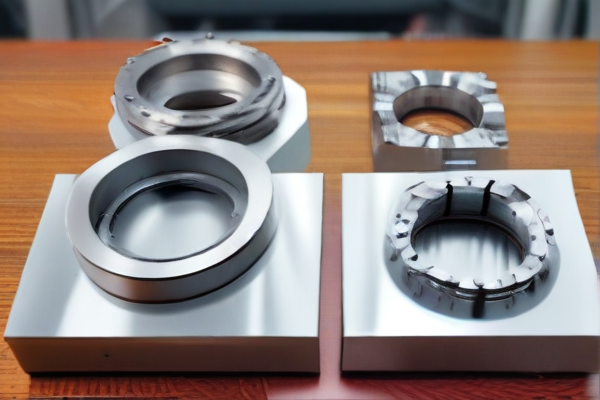

A CNC machinist is a skilled professional who operates and maintains CNC (Computer Numerical Control) machinery to produce precision metal and plastic parts. CNC machinists require knowledge of programming, setup, and machine maintenance.

– Programming: Create and modify CNC programs using CAD/CAM software.

– Setup: Prepare and configure CNC machines for specific tasks.

– Maintenance: Regularly inspect and maintain machinery to ensure optimal performance.

– Quality Control: Measure and inspect finished parts to ensure they meet specifications.

– Tooling: Select and install the correct tools for various machining tasks.

– Material Knowledge: Understand different materials and how they behave under machining processes.

– Troubleshooting: Diagnose and solve problems that arise during the machining process.

– Safety: Follow safety protocols to minimize risks associated with CNC machinery operation.

– Calibration: Regularly calibrate machines to maintain accuracy.

– Blueprint Reading: Interpret and understand technical drawings and blueprints.

– Project Management: Plan and manage machining projects from start to finish.

– Continuous Improvement: Stay updated with latest technologies and methods in CNC machining.

For advanced CNC machinists, skills may include:

– Advanced Programming: Proficiency with complex programming languages like G-code.

– Multi-Axis Machining: Experience with 5-axis or multi-axis CNC machines.

– Robotics Integration: Knowledge in integrating robotics for automation.

– CNC Milling: Specialize in CNC milling operations.

– CNC Turning: Specialize in CNC turning operations.

Career options include working in automotive, aerospace, medical device manufacturing, and more. Advanced CNC machinists may also pursue roles in supervision, quality assurance, or teaching.

– Educational Requirements: High school diploma or equivalent; trade school or associate degree often preferred.

– Certifications: Job-specific certifications can enhance job prospects.

– Experience Levels: Entry-level to advanced, with varying responsibilities and skills.

A CNC (Computer Numerical Control) machinist operates and programs automated machines to produce precision parts and components. They interpret technical drawings and use specialized software to ensure accuracy and efficiency.

Applications of CNC Machinists:

– Manufacturing: Produce parts for automotive, aerospace, and consumer products.

– Prototyping: Develop prototypes for new product designs.

– Medical Devices: Fabricate components for medical equipment and instruments.

– Electronics: Manufacture parts for electronic devices and gadgets.

– Aerospace: Create intricate aerospace components adhering to stringent specifications.

– Tool and Die Making: Craft tools, dies, and molds for mass production.

– Custom Parts: Develop custom and replacement parts for machinery.

– Quality Control: Inspect and ensure parts meet precise specifications and standards.

– Art and Sculpture: CNC machines are used in creating detailed sculptures and art pieces.

– Construction: Fabricate specialized parts for construction equipment.

– Hydraulics and Pneumatics: Produce components for hydraulic and pneumatic systems.

– Jewelry Making: Create intricate jewelry pieces with high precision.

– Renewable Energy: Craft components for solar panels and wind turbines.

– Education and Training: Teach CNC machining principles in educational institutions.

– Defense: Manufacture parts for defense equipment and vehicles.

– Robotics: Fabricate components for robotic systems.

– Marine Industry: Produce parts for boats and maritime equipment.

– Oil and Gas: Create components for drilling and extraction equipment.

– Packaging: Manufacture parts for packaging machinery.

– Furniture Making: Produce custom wooden or metal parts for high-end furniture.

CNC machinists play a crucial role across various industries by leveraging technology to achieve high precision and efficiency in manufacturing and production processes.

Certainly! Here’s a summary with each paragraph containing 20 to 30 words:

SourcifyChina delves into understanding what a CNC machinist is. A CNC machinist operates computer numerical control (CNC) machinery, essential for creating parts and tools by cutting, drilling, and designing materials with precision.

To become a CNC machinist, one must be adept in programming, handling multiple machine types, and understanding blueprints. They ensure every project meets exact specifications, demonstrating both technical and analytical skills.

Moreover, CNC machinists play a vital role in various industries, including automotive, aerospace, and manufacturing. Their expertise ensures high-quality production and precise component fabrication, critical for industry standards.

In conclusion, CNC machinists are the backbone of precision-based manufacturing. Their technical prowess not only drives efficiency but also innovation, forming a crucial link in modern industrial processes.

SourcifyChina is an established company specializing in sourcing and quality control across various manufacturing processes in China. They ensure that components and products meet international standards, enabling smooth supply chains for businesses globally.

A CNC machinist is a skilled professional who operates Computer Numerical Control (CNC) machines to produce precision parts. They interpret technical drawings, set up machinery, and monitor production to create components efficiently and accurately. CNC machinists play a vital role in modern manufacturing, ensuring parts meet exact specifications.

The quality control manufacturing process at SourcifyChina involves rigorous checks at multiple stages. Initial inspections assess raw materials, followed by in-process monitoring during production. Final inspections validate the end products against predefined criteria to ensure consistency and adherence to client specifications.

Using advanced equipment and trained inspectors, SourcifyChina conducts these thorough checks to maintain high standards. This meticulous approach minimizes defects, enhances product reliability, and ensures customer satisfaction. Comprehensive reporting and corrective actions are also part of their quality assurance strategy.

Through their quality control process, SourcifyChina adds significant value to the manufacturing workflow. They help mitigate risks, reduce waste, and optimize production, ultimately fostering trust and long-term partnerships with their clients.

SourcifyChina offers services that include skilled CNC machinists capable of precise, high-quality manufacturing. CNC machinists program, operate, and maintain CNC machines, ensuring parts meet specified tolerances.

These machinists at SourcifyChina are trained to interpret technical blueprints and transform raw materials into finished products. Using advanced software, they create and test CNC programs that control machine operations.

Quality control is a critical aspect of their role. CNC machinists regularly inspect machines and completed parts, making adjustments as needed to maintain quality. They often work closely with engineers to refine designs.

Safety and efficiency are also priorities. These machinists maintain a clean work environment and follow stringent safety protocols to prevent accidents and ensure the smooth functioning of machines.

In summary, SourcifyChina’s CNC machinists possess essential skills in programming, operation, quality control, and safety. Their expertise is crucial in delivering high-quality, precise manufactured parts, meeting client specifications efficiently and reliably.

A CNC (Computer Numerical Control) machinist operates sophisticated machinery to create precision parts and tools, playing a crucial role in manufacturing industries.

Advantages of Being a CNC Machinist:

– High Demand and Job Security:

CNC machinists are in high demand across various industries including automotive, aerospace, and medical devices, offering robust job security.

– Competitive Salaries:

Skilled CNC machinists often receive competitive salaries and benefits due to their specialized skill set.

– Technical Skills Development:

Operating CNC machines enhances technical skills in programming, blueprint reading, and machine maintenance.

– Career Advancement Opportunities:

Experience in CNC machining can lead to advancements into supervisory roles, programming, or even engineering positions.

– Contribution to Innovation:

CNC machinists play a key role in the development of innovative products, contributing to advancements in technology and manufacturing.

– Work Environment:

Jobs often take place in clean, well-organized, and technologically advanced facilities.

– Flexibility:

Opportunities exist in various industries, allowing machinists to transition between different sectors.

– Specialization:

CNC machinists can specialize in specific types of machining, such as milling, turning, or multi-axis machining, leading to niche expertise.

– Hands-On Work:

The role involves hands-on work and problem-solving, which can be satisfying and engaging for those who enjoy practical tasks.

– Job Satisfaction:

Many CNC machinists find satisfaction in creating tangible, high-quality products from raw materials.

– Training and Education:

Many entry-level positions only require vocational training or an associate degree, making it accessible without extensive higher education.

– Continuous Learning:

The field encourages ongoing learning and adaptation to new technologies and methods.

In summary, a career as a CNC machinist offers numerous benefits, from job security and competitive pay to opportunities for career advancement and continuous learning in a dynamic work environment.

A CNC (Computer Numerical Control) machinist operates CNC machines to create precision parts and components. These professionals combine technical skills and mechanical aptitude to bring engineering designs to life.

Key features of a CNC machinist include:

– Technical Proficiency: Understanding of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software.

– Machine Operation: Ability to set up and operate CNC machines, including lathes, mills, and routers.

– Blueprint Reading: Skilled in reading and interpreting engineering blueprints and technical drawings.

– Precision and Accuracy: Ensures high levels of precision and accuracy in the machining processes.

– Tool Selection: Knowledgeable in selecting the appropriate cutting tools and materials for each job.

– Quality Control: Monitors and inspects finished products to ensure they meet quality standards.

– Problem-Solving Skills: Quick to troubleshoot and resolve issues that occur during the machining process.

– Maintenance: Performs routine maintenance and minor repairs on CNC machinery.

– Safety Standards: Adheres to safety protocols and standards to maintain a safe working environment.

– Mathematical Skills: Proficient in math to calculate dimensions, tolerances, and machine feeds and speeds.

– Programming Skills: Competent in writing and modifying CNC machine programs.

– Collaborative Skills: Works well with engineers, designers, and quality control personnel to ensure product specifications are met.

Overall, CNC machinists play a crucial role in manufacturing, ensuring parts are produced accurately and efficiently, aligning with stringent industry standards.

SourcifyChina is a trusted partner for sourcing custom products and projects, providing top-quality manufacturing services in China. Specializing in various industries, they excel in bringing unique ideas to life with precision and efficiency.

A CNC (Computer Numerical Control) machinist plays a crucial role in manufacturing custom products. They operate CNC machines to cut, shape, and finish materials like metal, plastic, and wood into precise components as specified by design blueprints.

These machinists are highly skilled in programming CNC machines, setting up tools, and monitoring the production process to ensure each piece meets exact specifications. They are essential for producing intricate and consistent parts.

SourcifyChina utilizes CNC machinists to deliver high-quality custom products. Their expertise ensures that every project, whether simple or complex, adheres to stringent quality standards, making them a reliable choice for businesses seeking excellence in manufacturing.

The company works closely with CNC machinists to innovate and improve production techniques continually. This collaboration ensures that clients receive not only top-notch products but also efficient and cost-effective manufacturing solutions.

In summary, SourcifyChina’s use of expert CNC machinists ensures the creation of precise, custom products. Their dedication to quality and innovation makes them a premier choice for businesses looking to bring their custom projects to fruition with excellence and efficiency.

SourcifyChina is a dynamic company that notably positions itself at the forefront of China’s manufacturing sector by specializing in CNC (Computer Numerical Control) machining services. As a key player in this high-precision field, SourcifyChina provides comprehensive solutions tailored to meet the diverse needs of industries ranging from aerospace to electronics and automotive. A CNC machinist at SourcifyChina is a skilled professional tasked with programming, setting up, and operating CNC machines to fabricate intricate components from various materials such as metals, plastics, and composites. The machinists leverage advanced software and state-of-the-art machinery to ensure precision and efficiency in production, delivering parts that meet stringent industry standards. Beyond machining, SourcifyChina emphasizes continuous improvement and innovation, making it a preferred partner for companies seeking reliable, top-tier manufacturing services. The firm’s commitment to quality, combined with its adept machinists, positions it as a vital contributor to the global supply chain, enabling seamless production and scalability for clients.

A CNC (Computer Numerical Control) machinist specializes in operating precision machinery to fabricate complex components from various materials. In the aerospace sector, the role of a CNC machinist is critical for producing components that require extremely tight tolerances and high-quality finishes. Aerospace applications demand exacting standards due to the safety-critical nature of parts like turbine blades, structural components, and avionics housings. CNC machinists ensure that these components meet rigorous specifications by programming, setting up, and operating CNC machines, including lathes, mills, and grinders. Their expertise allows for the efficient production of lightweight, high-strength components that improve fuel efficiency, performance, and safety of aircraft.

In the defense and marine industries, CNC machinists also play a pivotal role in manufacturing. For defense applications, machinists create components for various military hardware, including weapons systems, armored vehicles, and communication equipment. Precision and reliability are paramount, as these components often operate under extreme conditions and stress. Similarly, in the marine industry, CNC machinists produce parts for ships, submarines, and offshore platforms. These components, such as propeller shafts, engine parts, and hull components, must be durable and resistant to harsh maritime environments. By leveraging advanced CNC technology, machinists can produce exceptionally accurate and robust parts essential for the reliability and longevity of both defense and marine equipment.

A CNC (Computer Numerical Control) machinist is a skilled professional who operates sophisticated machinery used in precision manufacturing processes. In the automotive industry, CNC machinists are indispensable for producing high-quality components that meet stringent performance and safety standards. They utilize CNC machines to fabricate intricate engine parts, transmission components, and chassis elements, ensuring exacting tolerances and repeatable accuracy. This precision is vital in an industry where even minor deviations can lead to significant performance and reliability issues. CNC machinists interpret complex blueprints and CAD (Computer-Aided Design) models to set up, program, and monitor the machinery, optimizing the production of parts critical for modern vehicles. Their work directly impacts the efficiency, durability, and safety of automobiles, making their role crucial in advancing automotive technology and production.

In the electronics sector, CNC machinists contribute to the creation of highly detailed and miniaturized components essential for today’s gadgets and devices. They are responsible for machining intricate circuit boards, connectors, and enclosures from various materials, including metals and plastics. This precision machining ensures that electronic components fit perfectly within devices such as smartphones, laptops, and medical equipment. Given the rapid advancement of electronics technology, CNC machinists must continually adapt to new materials and methods to stay ahead of industry requirements. Their expertise ensures that electronic products are not only functional and reliable but also meet the increasingly high standards of miniaturization and complexity. In both industries, the role of a CNC machinist is pivotal, as their meticulous work underpins the development and manufacturing of cutting-edge automotive and electronic innovations.

A CNC machinist, or Computer Numerical Control machinist, plays a pivotal role in the construction industry by operating and programming machines that create precise components used in various construction equipment and infrastructure. These machinists utilize CNC machines to fabricate parts from raw materials such as metal or plastic with high precision, ensuring that components fit together perfectly. This precision is particularly critical in the construction of buildings, bridges, and other structures, where even slight deviations can lead to significant issues. CNC machinists are responsible for understanding technical drawings and specifications, programming the CNC equipment to produce the desired parts, and maintaining the machines to ensure they operate efficiently. Their expertise is essential in producing custom parts for unique construction projects and in large-scale manufacturing of standardized components.

In the energy sector, CNC machinists contribute by manufacturing parts for renewable energy systems, traditional power generation equipment, and other energy infrastructure. For instance, CNC-machined parts are used in wind turbines, specifically in producing the intricate components of the gearboxes, rotor hubs, and other mechanical elements that must withstand significant stress and wear. Similarly, these machinists are crucial in the production of components for solar panels, bioenergy systems, and even in the construction of facilities for extracting and processing fossil fuels. By enabling the precise fabrication of components that meet strict industry standards, CNC machinists help ensure the reliability and efficiency of energy-generation systems. Their work supports advancements in energy technology, contributing to the overall stability and sustainability of energy supplies.

The industrial equipment industry extensively benefits from the expertise of CNC (Computer Numerical Control) machinists, who play a crucial role in manufacturing precision parts and components. CNC machinists operate sophisticated machinery that utilizes computer systems to control tools and devices, allowing for high levels of accuracy and consistency in the production process. These professionals are adept at reading blueprints, programming CNC machines, and performing quality checks to ensure that the manufactured parts meet stringent industry standards. Their skills are essential in industries such as automotive, aerospace, and healthcare, where precision-crafted components are critical for the performance and safety of various machinery and equipment.

In application, CNC machinists contribute to the optimization of production cycles by minimizing human error and reducing material waste. They ensure the efficient operation of machines like mills, lathes, and routers, which are essential for shaping metals, plastics, and other materials into intricate designs. The ability to produce complex geometries and tight tolerances makes CNC machining an invaluable process in developing advanced industrial equipment. Moreover, CNC machinists are pivotal in maintaining the operational integrity of manufacturing systems, providing critical troubleshooting and maintenance expertise. Thus, their role enhances productivity, supports innovation, and ensures the reliable production of high-quality industrial components that drive the industry forward.

A CNC (Computer Numerical Control) machinist plays a pivotal role in the medical device industry, where precision and reliability are paramount. These highly skilled professionals operate advanced machining equipment to fabricate intricate components used in medical devices such as surgical instruments, implants, and diagnostic machines. By interpreting complex technical drawings and utilizing specialized software, CNC machinists ensure that each component meets rigorous specifications and quality standards. Their expertise encompasses selecting appropriate materials, setting up machinery, and performing meticulous quality checks, which are all crucial in producing devices that enhance patient care and safety.

Moreover, the contributions of CNC machinists extend beyond mere fabrication; they are integral in the prototyping and innovation phases of medical device development. Their technical skills enable them to create precise prototypes rapidly, allowing for iterative testing and refinements. This capability accelerates the development lifecycle and facilitates the introduction of cutting-edge medical technologies. In an industry where technological advancements can significantly impact patient outcomes, the role of CNC machinists is indispensable. Their ability to combine craftsmanship with advanced technology ensures that medical devices are not only functional but also adhere to stringent regulatory and quality standards, ultimately contributing to the advancement of modern healthcare.

A CNC (Computer Numerical Control) machinist is a specialist responsible for operating and programming machine tools that create parts and components used in various manufacturing industries. The role requires a strong understanding of both the technical aspects of machinery and the software used in design and production. CNC machinists use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to plan and create intricate designs for production. They then translate these designs into a language understood by CNC machines, such as lathes, mills, and routers, ensuring precise execution. Their expertise ensures that manufacturing processes yield high-quality products with tight tolerances and consistent repeatability, crucial for industries ranging from aerospace to automotive and medical devices.

In the broader scope of machining and manufacturing, CNC machinists are integral to operational efficiency and product quality. They not only set up and maintain the machinery but also run quality checks throughout the production process, identifying and addressing any anomalies that may affect the final product. This role also demands a strong problem-solving ability to troubleshoot and resolve issues quickly, minimizing downtime and maintaining production schedules. In addition to technical skills, CNC machinists must prioritize safety and compliance with industry standards. As manufacturing continues to evolve with advancements in technology, the skills of CNC machinists remain invaluable, bridging the gap between digital design and physical production in a world increasingly reliant on precision-engineered components.

Sure! Below is a list of frequently asked questions (FAQ) with answers concerning the quality of work from CNC machinists at SourcifyChina Factory. Each question is given in bold tags.

Q1: What qualifications do CNC machinists at SourcifyChina Factory have?

A1: CNC machinists at SourcifyChina Factory are highly skilled professionals with extensive training and certifications in CNC machining. They undergo continuous education to stay updated with the latest technologies and techniques in the industry.

Q2: What materials can SourcifyChina process using CNC machining?

A2: SourcifyChina can handle a wide range of materials including metals (aluminum, steel, titanium, etc.), plastics (ABS, PEEK, PVC, etc.), and composites. Each material is meticulously chosen and processed to meet specific project requirements.

Q3: How does SourcifyChina ensure the quality of CNC machined parts?

A3: Quality assurance is paramount at SourcifyChina. We implement strict quality control measures including in-process inspections, post-production testing, and utilizing advanced measuring instruments like CMM (Coordinate Measuring Machines) to ensure all parts meet precise specifications.

Q4: What kind of CNC machines does SourcifyChina utilize?

A4: SourcifyChina employs state-of-the-art CNC machinery including 3-axis, 4-axis, and 5-axis milling machines, CNC lathes, and multi-tasking turning centers. This allows us to produce highly intricate and precise components efficiently.

Q5: Can SourcifyChina handle high-volume production runs?

A5: Yes, SourcifyChina is fully equipped to manage both low and high-volume production runs. Our scalable manufacturing capabilities and robust supply chain ensure timely delivery without compromising quality.

Q6: Does SourcifyChina provide custom CNC machining services?

A6: Absolutely. We offer custom CNC machining services tailored to meet unique client requirements. From prototyping to final production, we work closely with clients to ensure their specifications are met.

Q7: How does SourcifyChina communicate project progress?

A7: Communication is key at SourcifyChina. Clients receive regular updates on project milestones, and our team is always available to answer questions and provide support through various communication channels.

Q8: What industries does SourcifyChina serve?

A CNC machinist plays a crucial role in manufacturing at factories like SourcifyChina by operating Computer Numerical Control (CNC) machines. These machines are programmed to cut, shape, and finish materials to create precise and complex parts used in various industries, from automotive to aerospace.

1. Machine Setup: Preparing CNC machines and ensuring all tools and materials are in place.

2. Program Interpretation: Understanding and editing CNC programs to ensure accurate production.

3. Quality Control: Inspecting the produced parts for accuracy and conformity to specifications.

4. Maintenance: Performing routine maintenance to keep machines running efficiently.

– Technical Proficiency: Knowledge of CNC programming languages such as G-code.

– Attention to Detail: Precision is crucial, as even small errors can lead to significant issues.

– Problem-Solving: Ability to troubleshoot and resolve machining or programming issues.

– Physical Stamina: Often involves standing for long periods and handling heavy materials.

– High Precision: CNC machines offer unparalleled accuracy, essential for producing high-quality parts.

– Efficiency: Automation allows for faster production times and reduced human error.

– Versatility: Capable of working with a variety of materials including metals, plastics, and composites.

– Scalability: Easily adjustable settings enable the production of both small and large batches.

By leveraging the expertise of CNC machinists, SourcifyChina can produce highly precise and consistent products efficiently. Ensuring machinists are well-trained and the machines are properly maintained is critical for maintaining quality and meeting the demands of modern manufacturing.

Sure! Here’s a concise FAQ section regarding sourcing a CNC machinist from SourcifyChina factory:

Q1: What is a CNC machinist?

A1: A CNC (Computer Numerical Control) machinist is a skilled professional responsible for operating and maintaining CNC machines, which are used for cutting, shaping, and manufacturing precision parts from various materials. They use computer software to control machine tools and ensure accuracy in their output.

Q2: Why should I source a CNC machinist from SourcifyChina factory?

A2: SourcifyChina factory offers highly skilled CNC machinists, modern equipment, and cost-effective pricing. Their expertise ensures high precision and quality in manufacturing parts, making them a reliable choice for complex and detailed projects.

Q3: What qualifications and experience do CNC machinists at SourcifyChina possess?

A3: CNC machinists at SourcifyChina typically have technical education and extensive experience in operating various CNC machines. Many hold certification in CNC machining and continuously update their skills through training and industry workshops.

Q4: How do I ensure the quality of work from CNC machinists at SourcifyChina?

A4: SourcifyChina follows stringent quality control measures and industry standards. They offer detailed reports and product testing, including customer-specific inspections, to ensure their work meets the required specifications.

Q5: Can I get a customized manufacturing solution at SourcifyChina?

A5: Yes, SourcifyChina provides tailored solutions based on your requirements. Their CNC machinists collaborate with clients to design, prototype, and produce custom parts, ensuring the final product aligns with your specifications.

Q6: How do I start the process of sourcing a CNC machinist from SourcifyChina?

A6: To start, contact SourcifyChina with your project details, including part design and specifications. They will provide a quote and timeline for your project. You can then proceed with their professional team to bring your project to life.

Q7: What industries can benefit from CNC machining services at SourcifyChina?

A7: SourcifyChina’s CNC machining services are versatile and can serve various industries, including automotive, aerospace, medical, electronics, and consumer products, among others.

Q8: What materials can SourcifyChina’s CNC machinists work with?

When sourcing a CNC machinist from a Sourcify China factory, consider the following tips to ensure you find a qualified and reliable professional:

1. Understand CNC Machining: CNC (Computer Numerical Control) machining involves using automated, high-precision tools to produce components from various materials. Familiarize yourself with the basics to communicate effectively.

2. Define Requirements: Clearly specify the skills, experience, and qualifications needed. Typical requirements include proficiency in CNC programming, knowledge of various CNC machines, and experience with CAD/CAM software.

3. Sourcify Platform: Utilize Sourcify, a manufacturing sourcing platform, to streamline the process. It connects you with vetted factories and machinists in China, offering a reliable avenue to find skilled labor.

4. Factory Verification: Verify the factory’s credentials, compliance certifications, and past performance. Look for ISO certifications and positive reviews in their portfolio.

5. Request Samples: Ask for sample work to assess the quality and precision of their machining skills. Check for adherence to specifications and the overall finish of the product.

6. Communication: Ensure clear communication. Misunderstandings can lead to costly errors. Use detailed drawings, specs, and ensure the machinist understands your needs.

7. Technical Interview: Conduct a technical interview or test, if possible, to evaluate the machinist’s proficiency. Discuss past projects, problem-solving skills, and technical knowledge.

8. Contracts and Agreements: Ensure that all agreements, including confidentiality, IP protection, and terms of service, are documented and signed.

9. Price and Timeline: Negotiate the cost and delivery timeline upfront. Ensure these are reasonable and within your budget.

10. Feedback Loop: Establish a feedback mechanism to monitor progress and quality during the production process.

Following these tips can help you source a competent CNC machinist from a Sourcify China factory, leading to efficient and high-quality production.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.

How can I help you? :)