SourcifyChina Factory is an excellent choice for purchasing CNC mills from China due to its stringent quality control measures. This ensures buyers receive products that meet international standards and are durable, efficient, and reliable for various manufacturing needs.

Another key advantage of SourcifyChina Factory is its competitive pricing. By leveraging local resources and efficient manufacturing processes, the factory offers cost-effective solutions without compromising on quality, making it a valuable partner for global buyers.

SourcifyChina Factory also prides itself on its robust customer support. Their dedicated team assists buyers through every step of the purchasing process, from product selection to after-sales service, ensuring a smooth and satisfactory experience.

Moreover, the factory’s extensive industry experience enables it to understand and meet diverse customer requirements. Whether a buyer needs a standard CNC mill or a custom-designed model, SourcifyChina Factory has the expertise and flexibility to deliver.

In conclusion, choosing SourcifyChina Factory for purchasing CNC mills ensures high-quality products, competitive pricing, excellent customer support, and tailored solutions. This combination makes SourcifyChina a preferred partner for buyers seeking reliable and efficient CNC milling solutions from China.

A CNC (Computer Numerical Control) mill is a precision tool that uses computer programming to control machining processes. It automates the milling of materials into custom shapes and sizes with high accuracy.

Types and options for CNC mills include:

– Vertical CNC Mills: Vertical spindle orientation.

– Horizontal CNC Mills: Horizontal spindle orientation.

– 5-Axis CNC Mills: Five simultaneous axes of movement.

– CNC Router Mills: Ideal for woodworking, plastics, and non-ferrous metals.

– Bed Mill: Fixed worktable, moving spindle.

– Turret Mill: Spindle moves parallel and perpendicular to its axis.

– Mini CNC Mills: Compact and ideal for small parts and projects.

– Industrial CNC Mills: Large and powerful for heavy-duty machining.

– CNC Milling Machines with Tool Changers: Automatic tool changing capability.

– Simultaneous 4-Axis CNC Mills: Four axes operating simultaneously for complex shapes.

Each type offers distinct advantages, suitable for different applications ranging from hobbyist projects to high-volume industrial production.

A CNC mill is a computer-controlled machine tool used for precise and automated milling operations. It is widely used in various industries for cutting, drilling, and shaping materials like metal, wood, and plastic.

Applications of CNC milling include:

– Aerospace parts manufacturing

– Automotive components production

– Prototyping and custom parts creation

– Medical device fabrication

– Electronics housings and enclosures

– Furniture and cabinetry crafting

– Jewelry design and production

– Mold and die making

– Sculpting and engraving

SourcifyChina offers a detailed exploration of CNC mills, which are essential tools in modern manufacturing. CNC (Computer Numerical Control) mills are used to precisely cut and shape materials like metal, plastic, and wood. These machines are controlled by computer programs, allowing for high accuracy and repeatability in producing complex parts and components.

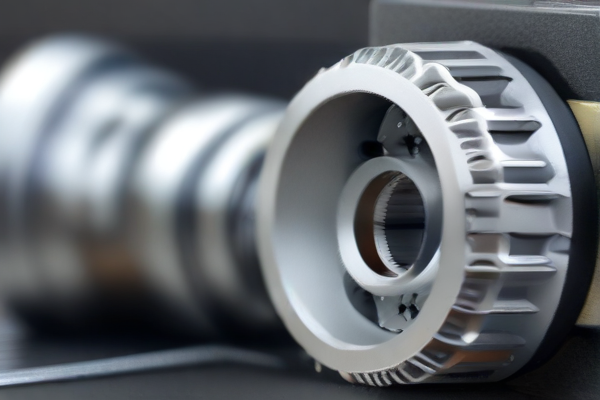

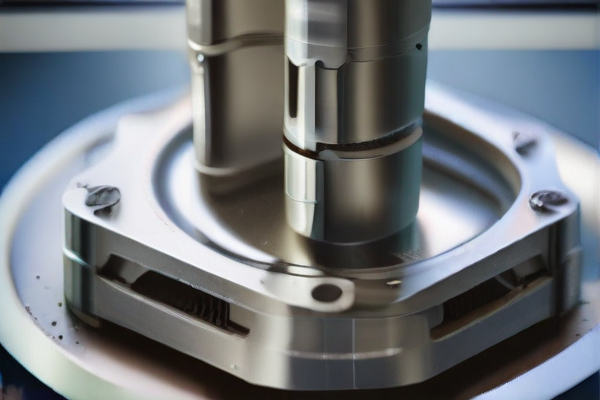

The main components of a CNC mill include the spindle, which holds the cutting tool, and the worktable, where the material is secured. Advanced CNC mills also feature automated tool changers and multiple axes of movement, enhancing their versatility and efficiency.

One key advantage of CNC mills is their ability to perform various machining operations such as drilling, milling, and tapping, all within a single setup. This reduces production time and increases consistency across manufactured parts. Additionally, CNC mills can operate continuously with minimal supervision, making them ideal for high-volume production environments.

SourcifyChina highlights the importance of choosing the right CNC mill based on specific manufacturing needs. Factors such as the size of the workpiece, material type, and desired precision level are crucial in selecting an appropriate machine. By understanding these aspects, manufacturers can optimize their processes and achieve superior product quality.

Overall, CNC mills are indispensable in modern manufacturing, offering unmatched precision, efficiency, and versatility. SourcifyChina’s guide provides valuable insights into the features and benefits of these powerful machines, helping businesses make informed decisions and stay competitive in the industry.

SourcifyChina specializes in precision CNC milling, ensuring high-quality manufacturing through a meticulous process. CNC milling, or Computer Numerical Control milling, uses computer-programmed commands to operate cutting tools, achieving exact specifications.

Quality control in CNC milling involves rigorous checks at each production stage. SourcifyChina employs advanced inspection techniques, including coordinate measuring machines (CMM), to verify dimensional accuracy. These inspections prevent defects and ensure parts meet stringent tolerances.

Materials used in CNC milling undergo thorough testing. SourcifyChina sources high-grade metals and plastics, performing hardness and tensile strength tests to guarantee durability and performance in final products.

The manufacturing process is continually monitored. Real-time data collection and analysis allow for immediate adjustments, minimizing errors and maximizing efficiency. This proactive approach maintains consistent quality throughout production.

Employee training is crucial for quality assurance. SourcifyChina invests in ongoing education, ensuring staff are skilled in the latest CNC technologies and quality control methodologies. Well-trained personnel are key to maintaining high standards.

SourcifyChina’s commitment to quality is reflected in their certifications. Compliance with international standards like ISO 9001 demonstrates their dedication to excellence. Regular audits and continuous improvement initiatives further solidify their reputation.

Customer feedback is integral to SourcifyChina’s process. By incorporating client insights, they refine techniques and address specific needs, enhancing overall satisfaction. This customer-centric approach fosters long-term partnerships.

Environmental considerations are also part of the quality control process. SourcifyChina implements sustainable practices, reducing waste and energy consumption. This commitment to sustainability aligns with global environmental standards.

In summary, SourcifyChina’s CNC milling quality control encompasses precise inspections, material testing, real-time monitoring, employee training, certifications, customer feedback, and environmental responsibility. This comprehensive approach ensures the production of superior, reliable components, meeting the highest industry standards.

SourcifyChina is a prominent company specializing in the sourcing and manufacturing of products, including CNC milling services. CNC milling, a key capability of SourcifyChina, involves the use of computer-controlled machines to precisely cut and shape materials such as metal, plastic, and wood. This technology enables the creation of intricate designs and complex geometries that would be difficult or impossible to achieve with manual machining.

The CNC mills at SourcifyChina are equipped with advanced features, such as multi-axis capabilities and high-speed spindles, which enhance precision and efficiency. These features allow for the production of components with tight tolerances and fine details, essential for industries like aerospace, automotive, and medical devices.

Moreover, SourcifyChina’s CNC mills support a wide range of materials, making them versatile for various applications. Whether it’s creating prototypes, custom parts, or mass production, the CNC milling services are tailored to meet specific project requirements. Their team of skilled engineers ensures each product meets the highest quality standards.

In addition to precision and versatility, SourcifyChina emphasizes efficiency and cost-effectiveness. By utilizing state-of-the-art CNC milling technology, they can reduce production times and minimize material waste, leading to more competitive pricing for their clients. This combination of advanced technology, expertise, and cost-efficiency makes SourcifyChina a reliable partner for CNC milling needs.

A CNC mill, or Computer Numerical Control mill, automates machining processes using programmed instructions to produce precise and complex parts.

Benefits of a CNC Mill:

– High Precision: Consistently produces parts with tight tolerances, ensuring accuracy.

– Efficiency: Reduces manual labor, increasing productivity and reducing production time.

– Versatility: Capable of machining a wide variety of materials, including metals, plastics, and composites.

– Complex Geometries: Easily creates intricate and complex shapes that would be difficult with manual machining.

– Consistency: Ensures uniformity in large production runs, minimizing human error.

– Cost-Effective: Reduces waste and rework, leading to cost savings over time.

– Automation: Allows for unattended machining, freeing up operators for other tasks.

– Scalability: Ideal for both small batches and large-scale production.

– Flexibility: Quick changeovers between different part designs without extensive setup.

– Integration: Compatible with CAD/CAM software for seamless design-to-production workflow.

A CNC mill is a computer-controlled machining tool that precisely removes material from a workpiece to create custom shapes. It’s widely used in manufacturing for its accuracy and efficiency.

Features

of a CNC Mill:

– Computer Control: Operates via pre-programmed software, ensuring precision and repeatability.

– High Precision: Capable of achieving tight tolerances, ideal for detailed and complex parts.

– Multi-Axis Capability: Often includes 3 to 5 axes, allowing for intricate and varied geometries.

– Material Versatility: Can work with metals, plastics, wood, and composites.

– Automated Tool Change: Enables the use of multiple tools for different operations without manual intervention.

– Real-Time Monitoring: Provides feedback on machine status, improving safety and reducing downtime.

– Large Work Area: Accommodates a variety of workpiece sizes.

– Integrated Safety Features: Includes emergency stop buttons and protective enclosures.

– User-Friendly Interface: Often comes with a touch screen or manual control panel for easy operation.

– Customizable Software: Supports a range of CAD/CAM software for designing and programming parts.

SourcifyChina is a leading platform for sourcing custom products and projects, specializing in CNC milling services. CNC milling is a manufacturing process that uses computer-controlled rotary cutters to remove material from a workpiece, creating precise shapes and designs.

CNC mills are highly versatile, capable of working with various materials, including metals, plastics, and wood. They are essential for producing complex components with high accuracy and consistency, ideal for custom manufacturing projects.

SourcifyChina leverages advanced CNC milling technology to offer tailored solutions to clients. Their expertise ensures high-quality, precision-engineered products, meeting diverse industry standards and specifications.

By utilizing CNC milling, SourcifyChina provides efficient and cost-effective production solutions. Their custom products range from prototypes to full-scale production runs, catering to industries such as automotive, aerospace, and consumer goods.

In summary, SourcifyChina’s CNC milling services deliver exceptional precision and customization, supporting various industries with reliable, high-quality manufacturing solutions. Their commitment to excellence ensures that clients receive the best possible products for their unique needs.

SourcifyChina is a prominent company that specializes in facilitating the procurement and manufacturing processes for businesses, particularly focusing on CNC milling. A CNC (Computer Numerical Control) mill is a sophisticated machine used in manufacturing to precisely cut and shape materials such as metal, wood, and plastic. By leveraging computer technology, CNC mills are capable of producing intricate and consistent parts with high precision and efficiency. SourcifyChina connects businesses with reliable CNC milling services, ensuring quality and cost-effectiveness. Their expertise in navigating China’s manufacturing landscape allows companies to streamline production, reduce costs, and maintain high standards of quality control. Through SourcifyChina, clients gain access to advanced CNC milling technology, which is essential for industries ranging from automotive to electronics, enabling them to stay competitive in a global market.

A CNC (Computer Numerical Control) mill is an advanced manufacturing tool used to machine precise and complex parts by automatically controlling machine tools via computer programming. In the aerospace, defense, and marine industries, CNC milling is indispensable due to its ability to produce components with high precision and tight tolerances. Aerospace applications frequently involve the creation of critical parts such as turbine blades, structural components, and engine parts. These components must endure extreme conditions and stresses, necessitating the superior accuracy and repeatability that CNC milling provides. Similarly, the defense sector relies on CNC mills to fabricate intricate parts for weapons systems, aircraft, and vehicles, ensuring that each part meets stringent safety and performance standards.

In the marine industry, CNC milling is utilized to produce various components, including propellers, engine parts, and structural elements of ships and submarines. The ability to machine complex geometries and high-strength materials makes CNC mills essential for creating parts that withstand harsh marine environments and prolonged exposure to saltwater. Moreover, CNC milling allows for the efficient production of custom parts and prototypes, which is crucial for innovation and the development of advanced technologies in these sectors. By enabling the precise and efficient manufacture of durable, high-performance parts, CNC milling plays a critical role in advancing the capabilities and reliability of aerospace, defense, and marine applications.

A CNC (Computer Numerical Control) mill is a precision manufacturing tool used extensively in the automotive industry for creating intricate components with high accuracy and repeatability. In automotive applications, CNC milling machines are utilized to produce engine parts, transmission components, and complex metal body parts. These machines can operate on various materials, including aluminum, steel, and composites, ensuring that each part meets stringent specifications and tolerances. The automation provided by CNC mills enhances production efficiency, reduces waste, and allows for the rapid prototyping of new designs, thus accelerating the development of innovative automotive technologies.

In the electronics industry, CNC mills are essential for fabricating circuit boards, enclosures, and other intricate parts that require high precision. The ability of CNC milling machines to produce finely detailed features makes them ideal for creating the complex geometries and tight tolerances needed in electronic components. This is particularly crucial in the production of microelectronics, where even the smallest deviation can impact functionality. CNC mills also allow for the customization of electronic devices, enabling manufacturers to tailor products to specific customer needs. Additionally, the capability to quickly switch between different milling tasks supports the fast-paced, ever-evolving nature of the electronics market, facilitating the rapid advancement of technology.

A CNC (Computer Numerical Control) mill is a precision tool used in the manufacturing process to machine a variety of materials, including metals, plastics, and composites. In the construction industry, CNC mills are vital for creating custom components and intricate architectural elements that require high precision and repeatability. For instance, CNC milling can produce complex metal frameworks, detailed moldings, and unique fixtures that are often integral to modern architectural designs. By using computer-aided design (CAD) software, construction professionals can translate complex blueprints into precise, physical components, ensuring that every part fits perfectly with minimal error. This not only speeds up the construction process but also enhances the structural integrity and aesthetic quality of the final build.

In the energy sector, CNC mills play a critical role in manufacturing components for various types of energy systems, including renewable energy technologies. For example, in wind energy, CNC milling is used to create precise parts for turbines, such as blades and gearboxes, which require high levels of accuracy to function efficiently and withstand harsh environmental conditions. Similarly, in the solar energy industry, CNC mills produce components for photovoltaic panels and mounting systems, ensuring they are manufactured to exact specifications for optimal performance. The ability of CNC mills to produce high-precision parts contributes significantly to the reliability and efficiency of energy systems, supporting the broader goal of enhancing energy production and sustainability. By leveraging CNC milling technology, the energy sector can improve the performance and lifespan of its infrastructure, leading to more sustainable and cost-effective energy solutions.

A CNC (Computer Numerical Control) mill is an industrial machine used for precise and automated machining processes. These mills are equipped with a computer system that controls the movement and operation of various tools, enabling them to produce highly accurate and complex parts with minimal human intervention. In the industrial equipment industry, CNC mills are essential for manufacturing components that require tight tolerances and intricate designs, such as gears, engine parts, and molds. The automation and precision offered by CNC milling significantly enhance production efficiency and consistency, reducing the likelihood of human error and enabling large-scale production runs with consistent quality.

The application of CNC mills in the industrial equipment sector extends beyond just manufacturing precision components. They play a crucial role in prototyping, allowing engineers to quickly and accurately produce prototype parts to test fit and function before mass production. Additionally, CNC mills are instrumental in custom manufacturing, where bespoke parts are required for specialized machinery or repairs. The flexibility of CNC milling machines to work with a variety of materials, including metals, plastics, and composites, makes them invaluable across multiple industries, from automotive to aerospace. Overall, CNC mills contribute to the innovation and advancement of industrial equipment by providing the capability to produce complex and precise parts efficiently.

A CNC (Computer Numerical Control) mill is a precision machining tool that is widely used in the production of medical devices due to its ability to create intricate and highly accurate parts. These mills operate under computer control, allowing for the automated, precise fabrication of components from various materials, including metals and plastics. The milling process involves the removal of material from a workpiece using rotary cutters, following a pre-programmed sequence designed in CAD (Computer-Aided Design) software. This capability is crucial in the medical field, where the exact dimensions and smooth finishes of implants, surgical instruments, and diagnostic equipment are critical for their performance and patient safety.

In the medical device industry, CNC mills play an essential role in manufacturing components such as prosthetic limbs, orthopedic implants, and dental devices. The precision of CNC milling ensures that these devices meet stringent regulatory standards and perform reliably in medical applications. Moreover, CNC milling allows for rapid prototyping and customization, enabling the production of patient-specific devices tailored to individual anatomical needs. This adaptability not only enhances the functionality and comfort of medical devices but also accelerates the development and iteration process, leading to faster advancements in medical technology and improved patient outcomes.

A CNC (Computer Numerical Control) mill is a highly automated machine tool that plays a crucial role in the machining and manufacturing industries. This machine utilizes computer-controlled commands to precisely cut and shape materials such as metals, plastics, and composites. By following pre-programmed instructions, CNC mills can perform a variety of operations, including drilling, boring, and contouring, with high accuracy and repeatability. The integration of advanced software allows for the creation of complex geometries and fine details that would be challenging or impossible to achieve manually. As a result, CNC milling is indispensable in producing intricate components for aerospace, automotive, medical, and consumer electronics industries.

In manufacturing, CNC mills enhance efficiency and productivity by significantly reducing the need for manual intervention and human error. Their ability to run unattended for extended periods enables continuous production cycles, which is essential for meeting high-volume demands and tight deadlines. Additionally, CNC mills contribute to cost savings by minimizing material waste and reducing setup times. The versatility of CNC milling extends to its compatibility with various materials, making it suitable for both prototyping and mass production. By leveraging the precision and flexibility of CNC mills, manufacturers can maintain consistent quality standards, improve turnaround times, and stay competitive in a rapidly evolving market.

What is CNC milling?

CNC (Computer Numerical Control) milling is a manufacturing process that uses computerized controls to operate and manipulate machine tools to produce precision parts and components. This technology ensures high accuracy and repeatability in creating complex shapes and designs.

What materials can be processed with CNC milling at SourcifyChina?

SourcifyChina’s CNC milling services can handle a variety of materials including metals (aluminum, steel, brass, titanium), plastics (ABS, polycarbonate, nylon), and composites. This versatility allows for the creation of parts for different industries.

How does SourcifyChina ensure the quality of CNC milled parts?

SourcifyChina adheres to stringent quality control measures throughout the manufacturing process. This includes using advanced CNC machines, skilled operators, and thorough inspection protocols such as dimensional checks, surface finish evaluations, and material testing.

What tolerances can SourcifyChina achieve with CNC milling?

SourcifyChina can achieve tight tolerances up to ±0.001 inches (±0.025 mm), depending on the material and part complexity. This precision ensures that parts meet the exact specifications required for your project.

How do I request a quote for CNC milling services from SourcifyChina?

To request a quote, you can submit your design files (such as CAD models or technical drawings) through SourcifyChina’s online portal or contact their sales team directly. Be sure to include material specifications, quantity, and any special requirements.

What is the typical lead time for CNC milled parts from SourcifyChina?

Lead times vary based on the complexity and volume of the order. However, SourcifyChina typically delivers CNC milled parts within 2-4 weeks from order confirmation. Expedited services may be available upon request.

Can SourcifyChina handle large volume CNC milling orders?

Yes, SourcifyChina is equipped to handle both small and large volume orders. Their scalable production capabilities ensure timely delivery and consistent quality regardless of the order size.

Are there any post-processing services available for CNC milled parts?

SourcifyChina offers various post-processing services such as anodizing, painting, powder coating, and heat treatment. These services enhance the durability and appearance of the finished parts.

For more detailed information or specific inquiries, please contact SourcifyChina directly.

A CNC mill, or Computer Numerical Control milling machine, is a versatile manufacturing tool used to automate the process of cutting and shaping materials like metal, plastic, and wood. SourcifyChina factory, known for its expertise in CNC machining, highlights several key aspects of CNC mill manufacturing:

1. Precision and Accuracy: CNC mills provide high precision and accuracy, capable of producing complex parts with tight tolerances. This is critical in industries where exact specifications are necessary, such as aerospace, automotive, and medical devices.

2. Automation and Efficiency: CNC mills are automated, reducing the need for manual intervention and increasing production efficiency. This leads to higher throughput and consistent quality, essential for mass production.

3. Versatility: CNC mills can handle a wide variety of materials and perform multiple operations like drilling, cutting, and milling. This versatility makes them suitable for prototyping as well as full-scale production.

4. Advanced Software Integration: These machines utilize advanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, allowing for precise control over the manufacturing process. This integration simplifies the transition from design to production.

5. Cost-Effectiveness: While the initial investment in CNC milling machines can be high, their efficiency and ability to produce high-quality parts quickly make them cost-effective in the long run. Reduced labor costs and minimized material waste also contribute to savings.

6. Customization and Flexibility: CNC mills can be programmed to create custom parts tailored to specific requirements, providing flexibility to adapt to various project needs.

7. Quality Control: SourcifyChina factory emphasizes stringent quality control measures, ensuring that each part meets the required standards. This includes routine inspections and use of precision measuring tools.

8. Skilled Workforce: Proper operation and maintenance of CNC mills require a skilled workforce. SourcifyChina ensures their technicians are well-trained to maximize machine performance and longevity.

Understanding these aspects can help businesses leverage CNC milling for efficient and high-quality manufacturing solutions.

FAQ: What is a CNC Mill from SourcifyChina Factory

What is a CNC mill?

A CNC (Computer Numerical Control) mill is a machine used in manufacturing that utilizes computer technology to control and automate the movement of tools and machinery. It precisely carves, cuts, and drills materials such as metal, plastic, and wood.

How does a CNC mill work?

A CNC mill operates by interpreting digital instructions from a computer program. These instructions control the movements of the machine’s cutting tools, allowing for precise and repeatable operations. The process involves loading a CAD (Computer-Aided Design) file into the machine, which then executes the design through a series of automated movements.

What materials can be processed with a CNC mill?

CNC mills can work with a wide range of materials including metals (aluminum, steel, titanium), plastics, wood, composites, and more. The versatility of the CNC mill makes it ideal for various industries, from automotive to aerospace and electronics.

What are the advantages of using a CNC mill?

Key advantages include high precision, repeatability, and efficiency. CNC mills can produce complex shapes and designs with a high degree of accuracy, reduce human error, and increase production speed. They are also capable of continuous operation, which enhances productivity.

What is the typical application of a CNC mill?

Typical applications include the production of parts for machinery, automotive components, aerospace parts, electronic enclosures, and custom-designed prototypes. CNC mills are also used in woodworking for creating intricate designs and components.

Why choose SourcifyChina Factory for CNC milling?

SourcifyChina Factory offers advanced CNC milling services with state-of-the-art equipment and experienced technicians. They provide high-quality, cost-effective solutions tailored to meet the specific needs of their clients, ensuring precision and timely delivery.

How can I get a quote for CNC milling services from SourcifyChina Factory?

To get a quote, you can visit the SourcifyChina Factory website and fill out the contact form with details about your project, including material specifications, design files, and quantity requirements. Their team will respond promptly with a customized quote.

When sourcing a CNC mill from SourcifyChina factory, consider these tips to ensure a smooth and successful procurement process:

1. Research and Define Specifications: Clearly outline the specifications you need, such as milling capabilities, size, material compatibility, precision, and software requirements. This helps in communicating your exact needs to the supplier.

2. Verify Supplier Credentials: Check SourcifyChina’s credentials, including certifications, manufacturing capabilities, and past customer reviews. Ensure they comply with international quality standards like ISO.

3. Request Detailed Quotations: Ask for comprehensive quotes that include the cost of the machine, shipping, taxes, and any additional fees. Compare these with other suppliers to get the best deal.

4. Quality Assurance: Inquire about the quality control processes in place at the factory. Request details on the materials used, manufacturing processes, and any testing protocols.

5. Customization Options: Determine if SourcifyChina offers customization for their CNC mills. Custom features can better align the machine with your specific operational needs.

6. Lead Times and Delivery: Clarify lead times for production and delivery. Ensure they can meet your required timeline and confirm the shipping method and associated costs.

7. After-Sales Support: Check the availability of after-sales support, including installation assistance, training, maintenance services, and warranty terms.

8. Sample Orders: If possible, request a sample order or a visit to the factory to inspect the quality and functionality of the CNC mills firsthand.

9. Payment Terms: Negotiate favorable payment terms that protect your investment, such as paying a portion upfront and the rest upon delivery or after installation.

10. Legal Considerations: Ensure all agreements are documented in a contract that covers specifications, delivery terms, payment conditions, and warranty clauses to protect both parties.

Following these steps can help you source a high-quality CNC mill from SourcifyChina factory effectively and efficiently.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.