Reliable Insights from Sourcify: Understanding the Role of a China Factory CNC Machine Operator

CNC (Computer Numerical Control) machine operators play a crucial role in China’s manufacturing sector, ensuring precision and efficiency. Discover their responsibilities and skills required to excel, as revealed by reliable data from Sourcify.

Choosing “SourcifyChina” Factory for purchasing CNC machine operators offers unparalleled quality and efficiency. Known for precision and reliability, their operators ensure optimal machine performance, crucial for high-stakes manufacturing.

“SourcifyChina” stands out with its rigorous training programs. Their CNC machine operators possess cutting-edge skills and expertise, adhering to international standards of excellence, making them highly sought after in the global market.

Additionally, “SourcifyChina” offers competitive pricing without compromising on quality. This cost-efficiency is particularly beneficial for buyers looking to maximize their budget while still obtaining top-notch operational capabilities.

With a strong focus on customer satisfaction, “SourcifyChina” provides excellent post-purchase support. Their team is always available to address any concerns, ensuring a smooth, hassle-free purchasing experience.

In conclusion, choosing “SourcifyChina” for CNC machine operators from China ensures high quality, cost efficiency, and exceptional customer service. Their commitment to excellence guarantees buyer satisfaction at every level.

A CNC machine operator is a skilled technician responsible for operating, maintaining, and programming CNC (Computer Numerical Control) machines, which are used for machining parts with precision. They read blueprints, set up machines, and ensure product quality.

Types of CNC Machines:

– Milling Machines

– Lathes

– Routers

– Plasma Cutters

– Laser Cutters

– Grinders

Options and Roles:

– Set-up Operator: Prepares and configures CNC machines before production.

– Programming Operator: Writes and modifies code for CNC operations.

– Machinist: Operates machines during production runs, ensuring consistent quality.

– Maintenance Technician: Handles regular maintenance and repairs of machines.

– Quality Control Inspector: Ensures finished products meet specified tolerances and standards.

Skills Required:

– Technical proficiency in machine operation and programming (G-code)

– Understanding of blueprints and engineering plans

– Critical thinking and problem-solving

– Attention to detail and precision

– Basic mathematics and computer knowledge

– Physical stamina and manual dexterity

Career Opportunities:

– Aerospace industry

– Automotive manufacturing

– Medical device production

– Electronics manufacturing

– Custom metal fabrication shops

Overall, CNC machine operators play a vital role in manufacturing industries, ensuring the efficient and precise production of various components and products.

A CNC (Computer Numerical Control) machine operator is responsible for setting up, operating, and maintaining CNC machines which are used to cut, shape, and finish metal and other materials. These professionals interpret blueprints and technical drawings to create precise components.

Applications include:

– Aerospace: Crafting intricate components for aircraft.

– Automotive: Manufacturing engine parts and car frames.

– Medical Devices: Producing high-precision surgical instruments.

– Electronics: Creating parts for computers and smartphones.

– Furniture Making: Shaping wooden parts for custom furniture.

– Military: Producing specialized equipment for defense.

– Industrial Equipment: Crafting components for machines.

– Tool and Die Making: Creating molds and dies for manufacturing.

– Signage: Cutting and engraving bespoke signs.

– Jewelry: Engraving and cutting intricate designs.

– Prototyping: Producing custom prototypes quickly.

– Arts and Crafts: Carving detailed artistic pieces.

– Construction: Shaping materials for custom builds.

– Shipbuilding: Crafting parts for ships and submarines.

CNC machine operators play a crucial role across multiple industries, ensuring high precision and efficiency in production.

A CNC (Computer Numerical Control) machine operator plays a crucial role in manufacturing by handling precision instruments to machine parts from various materials. They read and interpret blueprints, set up, and operate CNC machinery to produce high-quality components, ensuring exact compliance with design specifications.

Operators of CNC machines typically require a blend of technical skills and an understanding of machinery programming languages. Their daily tasks involve loading raw materials, selecting appropriate tools, and adjusting machine parameters to maintain high manufacturing standards. They often inspect finished products for defects to ensure optimal output and consistency.

The responsibilities of a CNC machine operator also include routine maintenance and troubleshooting of equipment. This proactive care helps in minimizing downtime and ensures steady, efficient production. Proficiency in the use of machining tools, like lathes and mills, is essential for precise modifications to the workpiece.

Operators should have a keen eye for detail and strong problem-solving abilities. Additionally, handling CNC machinery involves strict adherence to safety protocols to prevent workplace accidents. Continuous learning and skill enhancement are vital as technology and machining techniques advance.

In conclusion, CNC machine operators are essential to modern manufacturing, requiring a combination of technical aptitude, meticulous attention to detail, and a commitment to safety and quality control. Their expertise ensures that intricate designs are precisely executed, supporting the production of high-quality parts and components.

SourcifyChina ensures precision in its manufacturing processes by employing skilled CNC machine operators. These operators control computer numerical control (CNC) machines, crucial for producing intricate parts with high accuracy.

The CNC machine operator programs the equipment, loading materials, and monitors the machining process. They ensure that the machinery functions efficiently to produce parts that meet exact specifications, reducing waste and improving productivity.

Quality control is integral to SourcifyChina’s operations. Every product undergoes rigorous inspections to guarantee it meets industry standards and client requirements. Defective items are meticulously identified and corrected to maintain high quality.

The manufacturing process at SourcifyChina involves continuous improvements. Regular training and updates on the latest technologies allow CNC machine operators to enhance their skills and adapt to new challenges. This ensures they’re always at the forefront of precision manufacturing.

Reliable quality control systems at SourcifyChina boost customer satisfaction. Consistent monitoring and adherence to quality standards ensure that products not only meet but often exceed expectations. This meticulous approach reduces returns and increases client trust.

In summary, SourcifyChina’s effective blend of skilled CNC machine operators and stringent quality control measures guarantees a smooth, high-quality manufacturing process. This commitment to excellence drives their reputation for delivering precise, reliable products to global clients.

SourcifyChina’s CNC machine operators are integral to precision manufacturing, leveraging advanced technologies to produce intricate components. Their skills ensure high-quality output and minimal waste, driving efficiency and consistency in product creation.

These operators interpret complex blueprints, input technical data, and perform regular machine maintenance. Their expertise guarantees that CNC machines operate at optimal levels, reducing downtime and maintaining production schedules.

Operators are also adept at troubleshooting and resolving any mechanical issues that arise, ensuring continuous operation. This problem-solving ability significantly contributes to the smooth functioning of manufacturing processes.

A crucial aspect of their role involves quality control. Operators meticulously inspect the finished components, ensuring they meet stringent specifications and industry standards. This attention to detail is critical for maintaining product integrity and customer satisfaction.

In addition to technical prowess, CNC machine operators at SourcifyChina possess strong analytical skills and a keen eye for detail. Their ability to balance multiple tasks while maintaining stringent quality control ensures the seamless execution of manufacturing processes, fortifying SourcifyChina’s reputation for excellence.

A CNC machine operator plays a crucial role in modern manufacturing, offering precision, efficiency, and flexibility in producing complex and consistent parts.

Benefits Include:

– Precision and Accuracy: CNC machines operate with high accuracy, ensuring consistent product quality.

– Efficiency: Automates production processes, reducing manual labor, and increasing throughput.

– Versatility: Capable of producing various parts and products using different materials.

– Reduce Human Error: Minimizes mistakes common in manual machining.

– Cost Savings: Lowers manufacturing costs through reduced waste and faster production times.

– Safety: Lessens the likelihood of accidents by limiting human intervention.

– Scalability: Easily scales production volume without compromising quality.

– Complex Geometry: Can create intricate designs and shapes that are difficult with traditional methods.

– Consistency: Ensures uniformity across multiple production runs.

– Minimal Skill Requirement: Basic training suffices for operation, making it accessible for workers.

Utilizing CNC technology advances production capabilities, optimizing both small and large-scale manufacturing processes.

A CNC machine operator is a skilled professional responsible for operating Computer Numerical Control (CNC) machines, which are used in manufacturing to produce precise and complex parts from raw materials.

Key Responsibilities:

– Machine Setup: Install and configure CNC machines before starting the production process.

– Programming: Input or edit machine control programs to ensure accurate part production.

– Quality Control: Inspect finished parts to ensure they meet design specifications and quality standards.

– Maintenance: Perform routine maintenance and troubleshooting to keep machines running efficiently.

– Safety Compliance: Follow safety guidelines and protocols to ensure a safe working environment.

– Record Keeping: Maintain accurate records of machine performance, production output, and any issues encountered.

Essential Skills:

– Technical Proficiency: Understanding of CNC machinery, programming languages (like G-code), and blueprints.

– Attention to Detail: High level of precision to ensure parts meet stringent specifications.

– Problem-Solving: Quick thinking to diagnose and fix issues during machining operations.

– Mechanical Aptitude: Good grasp of mechanics and industrial processes.

– Computer Literacy: Ability to use computer software for programming and monitoring CNC machines.

Work Environment:

– Manufacturing Setting: Typically employed in factories, workshops, and production facilities.

– Shift Work: May include different shifts, including nights and weekends, depending on production needs.

– Team Collaboration: Often work alongside engineers, quality control specialists, and other machine operators.

Certification and Training:

– Educational Background: Vocational training, associate degree in CNC machining, or related field.

– On-the-Job Training: Practical experience and company-specific training.

– Certification: Optional certifications from recognized institutions can enhance job prospects.

CNC machine operators are integral to modern manufacturing, ensuring that parts are produced with high precision and efficiency, contributing to various industries such as automotive, aerospace, and medical devices.

SourcifyChina is known for its expertise in custom products and projects, providing tailored manufacturing solutions for clients worldwide. One of the key areas they excel in is operating CNC machines, which are essential for precise and efficient production.

A CNC (Computer Numerical Control) machine operator plays a crucial role in this process. They are responsible for programming, setting up, and operating CNC machines to produce parts and components according to specific design and quality requirements.

CNC machine operators must possess a thorough understanding of the machinery and software used in the process. They need to read technical drawings, set machine parameters, and monitor the production to ensure that the final product meets the exact specifications.

Quality control is a significant part of a CNC machine operator’s job. Operators perform regular inspections and adjustments during the production run to maintain high standards and prevent defects, ensuring that every custom product meets the client’s expectations.

At SourcifyChina, CNC machine operators are essential to the success of custom projects. Their skills and expertise enable the company to deliver high-quality, precision-engineered products for various industries. By combining advanced technology with skilled craftsmanship, SourcifyChina continues to set the standard for custom manufacturing solutions.

SourcifyChina is an emerging leader in the manufacturing sector, specializing in connecting global businesses with reliable CNC (Computer Numerical Control) machine operators in China. Known for its meticulous approach to sourcing, SourcifyChina ensures that clients receive top-quality services from highly skilled operators who can handle intricate tasks across various industries, including automotive, aerospace, and medical devices. A CNC machine operator at SourcifyChina is proficient in operating sophisticated machinery that transforms raw materials into precise, custom-designed components. These operators are adept at reading technical blueprints, programming CNC machines, and conducting rigorous quality checks to ensure each product meets exact specifications. SourcifyChina’s commitment to excellence and unparalleled expertise in CNC machining make it a preferred partner for companies seeking precision, efficiency, and reliability in their manufacturing processes. With a keen focus on quality control and timely delivery, SourcifyChina paves the way for seamless production and cost-effective solutions, earning the trust of its international clientele.

A CNC (Computer Numerical Control) machine operator plays a pivotal role in the aerospace, defense, and marine industries, where precision and reliability are paramount. In aerospace applications, CNC operators are responsible for fabricating components like turbine blades, airframes, and landing gear from advanced materials such as titanium and composites. These components must adhere to exacting standards for safety and performance. The CNC machine operator programs the machinery based on the intricate designs provided by engineers, ensuring microscopic tolerances are met. Their expertise ensures that every part produced can withstand the extreme conditions encountered in aerospace endeavors, from high-altitude flight to re-entry into the Earth’s atmosphere, thereby contributing to the safety and efficiency of aircraft and spacecraft.

In the defense and marine sectors, CNC machine operators also play a crucial role in manufacturing critical components, albeit with different sets of challenges and requirements. For defense, this might include parts for military vehicles, firearms, and communication systems—all requiring exact precision to ensure operational reliability under combat conditions. Similarly, in the marine industry, these operators craft parts for submarines, vessels, and offshore platforms. They must account for factors like corrosion resistance and structural integrity to ensure these components perform optimally in harsh oceanic environments. By leveraging CNC technology, operators produce parts that meet stringent defense and marine specifications, making them indispensable in crafting machinery and structures that can endure the rigors of use in these demanding industries.

In both contexts, the CNC machine operator’s role is indispensable in turning design blueprints into actual, high-quality parts critical for the functionality and safety of advanced systems.

A CNC (Computer Numerical Control) machine operator in the automotive industry plays a pivotal role in manufacturing precision components that meet stringent quality standards essential for vehicle performance and safety. They use advanced CNC machinery to fabricate engine parts, drive shafts, transmission components, and intricate brackets, ensuring each piece is within tolerance specifications. With the automotive industry’s shift towards electric and hybrid vehicles, the role of a CNC machine operator has expanded to include the production of battery housings and electric drivetrain components. Operators meticulously oversee machining processes, adjusting tool paths and parameters to minimize material waste and maximize efficiency. Their expertise ensures that each automotive part is produced consistently, meeting the rigorous demands of mass production while maintaining high quality.

In the electronics sector, CNC machine operators are essential in crafting precision components for a wide array of devices, ranging from consumer electronics to sophisticated medical equipment. They configure and manage CNC machines to produce intricate circuit boards, heat sinks, and electronic enclosures with exceptional accuracy. Operators are adept at working with high-performance materials, including aluminum, copper, and specialized plastics, to manufacture parts that require tight tolerances and flawless finishes. As the demand for miniaturized, high-performance electronics increases, CNC operators adapt to newer, more complex machining techniques. Their role is crucial in ensuring that electronic components not only fit seamlessly within compact designs but also meet stringent electromagnetic compatibility and thermal management requirements. Through their precision and skill, CNC machine operators contribute significantly to the advancement of technology in the electronics industry.

A CNC (Computer Numerical Control) machine operator in the construction industry plays a pivotal role in the precision manufacturing of building components, which are fundamental to the integrity and functionality of construction projects. Utilizing advanced software and machinery, these operators program and oversee automated machines that are capable of producing detailed structural elements such as beams, columns, and intricate architectural designs. The expertise of a CNC machine operator ensures that materials are cut, shaped, and finished within tight tolerances, which mitigates human error and improves the overall quality and efficiency of construction processes. By streamlining production, CNC machine operators significantly reduce labor costs and time, while enhancing the safety and reliability of construction projects.

In the realm of energy, CNC machine operators contribute to the creation of highly specialized equipment and components that are essential for energy production and distribution. Whether in the fabrication of precision parts for turbines in renewable wind energy, the detailed components of nuclear reactors, or the intricate piping systems in oil and gas extraction, CNC operators ensure that each part meets stringent industry standards. Their role is crucial for the operational efficiency and longevity of energy systems, as precision in manufacturing reduces the risk of machinery failure and downtime. Additionally, the adoption of CNC technology in energy applications promotes the development of innovative solutions and the incorporation of advanced materials, ultimately leading to more sustainable and efficient energy systems.

In the industrial equipment industry, a CNC (Computer Numerical Control) machine operator plays a pivotal role in the manufacturing process. These operators are skilled professionals responsible for setting up, maintaining, and operating CNC machines that fabricate parts and products from raw materials. By interpreting technical drawings and blueprints, CNC machine operators program the machines to execute precise movements and cuts, ensuring that the end products meet stringent specifications. Their expertise allows for the production of complex components with high accuracy and consistency, essential in industries such as automotive, aerospace, and heavy machinery manufacturing.

The application of CNC machine operators in the industrial equipment industry extends beyond mere operation. They are also tasked with performing routine maintenance and troubleshooting to minimize downtime and maintain the efficiency of the production line. CNC machine operators must possess a strong understanding of both the mechanical and software aspects of the machines they handle, enabling them to make adjustments and corrections as needed. Their role is critical in achieving optimal productivity and quality control, as they ensure that the manufacturing process adheres to industry standards and customer requirements. This precision and efficiency directly contribute to the competitiveness and innovation within the industrial equipment sector.

Computer Numerical Control (CNC) machine operators play a crucial role in the medical devices industry. These skilled professionals operate sophisticated machinery that utilizes pre-programmed software to dictate the movement of tools and machinery, enabling the precise manufacturing of complex medical devices. High precision is indispensable when producing components such as orthopedic implants, dental implants, and cardiovascular stents, where even microscopic deviations can result in significant clinical implications. CNC machine operators meticulously monitor and control the manufacturing process, ensuring that each component meets stringent quality standards and regulatory requirements. Their expertise helps translate the intricate designs into tangible products that can improve patient outcomes and advance medical technologies.

Beyond merely operating the machinery, CNC machine operators in the medical devices industry often collaborate closely with engineers and designers. This synergy ensures that the final products are not only manufactured to exact specifications but also optimized for functional performance and reliability. In addition to technical prowess, CNC operators need a deep understanding of the materials commonly used in medical devices, such as titanium, stainless steel, and various biocompatible polymers. Expertise with these materials ensures that the devices produced are durable and safe for use in medical applications. Through their precision and collaborative efforts, CNC machine operators significantly contribute to the innovation and production of life-enhancing medical devices, making them indispensable members of the healthcare manufacturing ecosystem.

A CNC (Computer Numerical Control) machine operator is a skilled technician responsible for operating and maintaining CNC machines, which are automated tools used in machining and manufacturing to precisely cut, shape, and finish metal, plastic, or wood components. These machines are programmed via computer software to perform a variety of tasks with high accuracy and repeatability, making them essential in producing parts for industries such as aerospace, automotive, and medical devices. CNC machine operators set up the machines by installing the correct tools, inputting the required specifications, and adjusting the machine settings to ensure optimal performance. They monitor the machining process to ensure that the parts produced meet the desired specifications and make adjustments as necessary to maintain quality.

In addition to operating the machines, CNC machine operators are also responsible for routine maintenance and troubleshooting to prevent and resolve any issues that may arise during production. This includes cleaning and lubricating the machines, replacing worn-out tools, and performing minor repairs. The role requires a deep understanding of the machinery, the materials being used, and the software that controls the machines. Operators must also be proficient in reading blueprints and technical drawings to accurately translate designs into physical parts. The precision and efficiency offered by CNC machines, combined with the expertise of CNC machine operators, play a critical role in modern manufacturing, enabling the production of complex and high-quality components at scale.

Sure, here is a list of frequently asked questions (FAQ) with answers regarding CNC machine operator quality work from SourcifyChina factory:

What is a CNC machine operator?

A CNC machine operator is a skilled professional responsible for operating CNC (Computer Numerical Control) machines. These machines are automated tools controlled by computer software to produce high-precision components. Operators ensure that machines are running properly, monitor production, and perform some minor maintenance tasks.

What qualifies as high-quality work for a CNC machine operator?

High-quality work for a CNC machine operator is defined by precise machining, adherence to design specifications, efficient production, minimal errors, and exemplary finish. Quality work often involves attention to detail, ensuring measurements are exact, and following stringent industry standards.

How does SourcifyChina ensure the quality of its CNC operations?

SourcifyChina maintains high-quality standards through rigorous training programs for operators, regular maintenance of CNC machines, and strict adherence to international quality certifications. Additionally, every product undergoes multiple quality checks and inspections before dispatch.

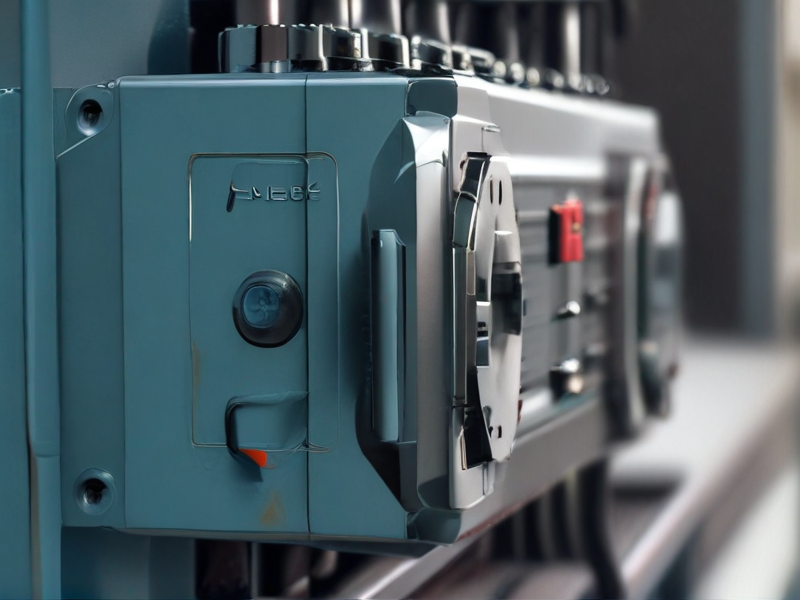

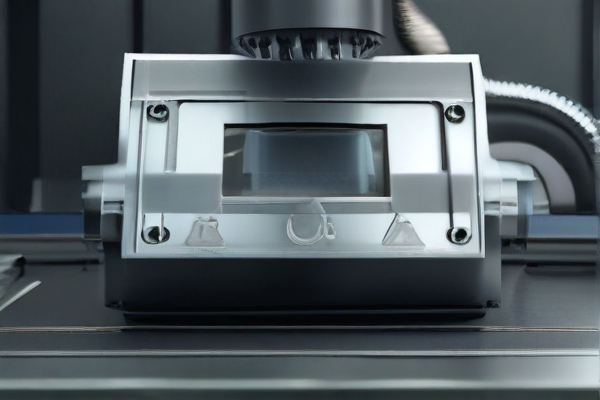

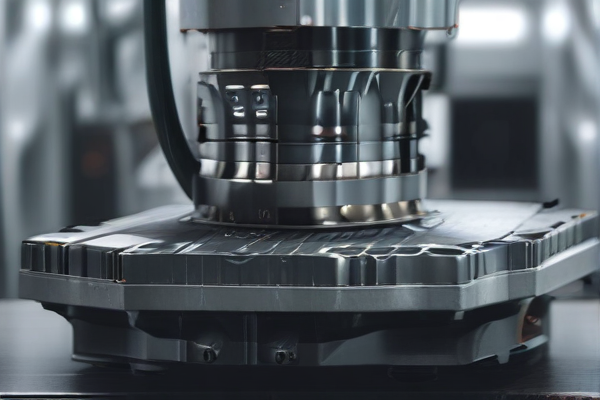

What types of CNC machines are used at SourcifyChina?

SourcifyChina employs a range of CNC machines including CNC milling machines, CNC lathes, and CNC routers. Each type of machine specializes in different kinds of cutting, drilling, and shaping tasks to meet diverse manufacturing needs.

Are the operators at SourcifyChina certified?

Yes, operators at SourcifyChina are highly trained and certified to ensure they meet both national and international standards. They undergo continuous training to stay updated with the latest technologies and best practices in CNC machining.

What materials can SourcifyChina CNC machines handle?

SourcifyChina’s CNC machines can handle a variety of materials including metals (like aluminum, steel, and titanium), plastics, composites, and more. This versatility enables them to cater to a broad spectrum of industries.

Can SourcifyChina provide customized CNC machining solutions?

Absolutely, SourcifyChina prides itself on providing tailored CNC machining services to meet specific customer requirements. Customization options are available for different industries ranging from automotive to aerospace and beyond.

What are the steps to ensure dimensional accuracy in CNC machining?

To ensure dimensional accuracy, SourcifyChina follows a meticulous process which includes thorough design reviews, the use of precise measurement tools, regular calibration of machines, and multiple inspection stages throughout the manufacturing process.

These FAQs should provide a clearer understanding of CNC machine operator quality work at SourcifyChina factory.

A CNC (Computer Numerical Control) machine operator in a manufacturing context, such as at a SourcifyChina factory, is responsible for operating machines that perform tasks like cutting, drilling, or milling materials. Here are some key tips and responsibilities for a CNC machine operator:

1. Understanding Blueprints and Schematics:

– Interpret technical drawings and blueprints to understand the specifications and tolerances required for each part.

2. Machine Setup:

– Set up CNC machines by installing and aligning tools and workpieces. This includes loading materials and selecting the right tools for the job.

3. Programming and Calibration:

– Input or adjust machine programs as needed. This involves understanding G-code or other CNC programming languages.

– Calibrate machines to ensure precision and accuracy, adjusting settings to meet specified tolerances.

4. Operation and Monitoring:

– Operate the CNC machine, ensuring it runs smoothly and efficiently. Monitor the process to detect any issues or malfunctions.

– Make necessary adjustments during operations to maintain quality and efficiency.

5. Quality Control:

– Inspect finished parts for accuracy, using precision measuring tools like calipers and micrometers.

– Ensure that all products meet quality standards and specifications.

6. Maintenance and Troubleshooting:

– Perform routine maintenance on machines to prevent downtime.

– Troubleshoot and resolve any issues that arise during the manufacturing process.

7. Safety and Compliance:

– Follow all safety protocols to ensure a safe working environment.

– Comply with all company policies and regulatory requirements related to manufacturing and machine operation.

8. Continuous Improvement:

– Suggest and implement process improvements to enhance efficiency and quality.

– Stay updated with new technologies and methods in CNC machining.

By mastering these areas, CNC machine operators at factories like SourcifyChina can significantly contribute to efficient, high-quality production processes.

Sure, here are some frequently asked questions (FAQ) with answers about sourcing CNC machine operators from SourcifyChina factory:

1. What is a CNC machine operator?

A CNC (Computer Numerical Control) machine operator is a skilled technician responsible for operating and maintaining CNC machines that perform various manufacturing tasks. They work with precision programs to control the output and quality of the crafted components.

2. Why should I consider sourcing CNC machine operators from SourcifyChina factory?

SourcifyChina factory provides highly trained and experienced CNC machine operators who can handle intricate and complex manufacturing requirements. Their operators are proficient in operating advanced machines, ensuring high-quality production with increased efficiency and reduced errors.

3. How skilled are the CNC machine operators at SourcifyChina?

The CNC machine operators at SourcifyChina factory are highly skilled, possessing thorough technical knowledge and hands-on experience. They are adept in programming, machine setup, operation, and troubleshooting to ensure production runs smoothly and efficiently.

4. What types of CNC machines can operators from SourcifyChina handle?

Operators from SourcifyChina are capable of handling a wide range of CNC machines including lathes, mills, routers, and grinders. They are trained to operate both 3-axis and multi-axis CNC machines for various manufacturing applications.

5. Can SourcifyChina factory provide CNC machine operators for short-term projects?

Yes, SourcifyChina factory can provide CNC machine operators for both short-term and long-term projects, tailored to meet your specific production needs and timelines.

6. How does SourcifyChina ensure the quality and reliability of their CNC machine operators?

SourcifyChina employs rigorous selection and training processes to ensure that their CNC machine operators meet high standards. Continuous professional development and quality assurance practices are in place to maintain reliability and performance.

7. What are the costs associated with sourcing CNC machine operators from SourcifyChina?

Costs can vary depending on the duration and complexity of the project. SourcifyChina offers competitive pricing tailored to your specific requirements, ensuring cost-effective solutions without compromising quality.

8. How can I get in touch with SourcifyChina to discuss my CNC machine operation needs?

You can contact SourcifyChina through their website or customer service hotline to discuss your requirements. Their team will assist you in finding the best CNC machine operators for your projects.

These answers should help you understand the basics of how CNC machine operators from SourcifyChina factory can benefit your manufacturing processes.

When sourcing information or services about CNC machine operators, especially from a platform like SourcifyChina, it’s crucial to follow a strategic approach. Here are some tips to help you:

1. Define Your Needs: Clearly outline what you need from a CNC machine operator, including the types of machines (e.g., milling, turning), materials (e.g., metals, plastics), and specific skills or certifications required.

2. Use Precise Keywords: When searching on SourcifyChina, use specific keywords like “CNC machine operator,” “CNC machinist,” or “CNC manufacturing services.” This helps in narrowing down the most relevant suppliers or manufacturers.

3. Evaluate Supplier Profiles: Look for suppliers who have detailed profiles, including information about their CNC machinery, capacity, certifications (like ISO9001), and client feedback. High-quality suppliers often provide comprehensive descriptions of their capabilities.

4. Request Documentation: Verify the operator’s qualifications and the company’s capabilities. Request documentation such as certification copies, a list of machine models, and details on quality control procedures.

5. Ask for Samples: To ensure quality, ask for sample parts to be produced. Evaluate these samples for precision, surface finish, and compliance with your specifications.

6. Communicate Clearly: Maintain clear and concise communication with potential suppliers. Use diagrams, technical drawings, and clear instructions to convey your requirements.

7. Check Lead Times and Pricing: Confirm that the supplier can meet your lead times and budget. Compare quotes from multiple suppliers to get a fair market rate.

8. References and Reviews: Look for reviews or ask for referrals from past clients. Reliable suppliers often have a proven track record of delivering quality work.

By following these steps, you can efficiently source a competent CNC machine operator through SourcifyChina, ensuring that your manufacturing needs are met with precision and reliability.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.