Understanding

Galvanized Metal: Reliable Insights from SourcifyChina’s Factory

Discover the fundamentals of galvanized metal, provided by the trusted experts at SourcifyChina’s factory. Learn how the galvanization process fortifies metal against corrosion, ensuring durability and long-lasting quality for your manufacturing needs.

Choosing SourcifyChina for purchasing galvanized metal from China ensures high-quality products, competitive pricing, and exceptional customer service. Their established network of reliable manufacturers guarantees efficient and timely delivery, catering to your specific needs.

With extensive experience in the Chinese manufacturing industry, SourcifyChina stands out for its rigorous quality control measures, ensuring you receive only the best galvanized metal. Their commitment to excellence makes them a trusted partner.

Moreover, SourcifyChina offers comprehensive support, from initial inquiries to post-purchase service. Their knowledgeable team assists with every step, providing seamless communication and addressing any concerns swiftly, ensuring a hassle-free buying experience.

Completing the package, SourcifyChina prioritizes long-term relationships with clients, offering flexible terms and continuous improvements to meet evolving market demands. Their dedication to customer satisfaction makes them the ideal choice for your galvanized metal needs.

Galvanized metal is steel coated with a protective layer of zinc to prevent rusting and corrosion. It is widely used in construction, automotive, and household applications.

Types and Options:

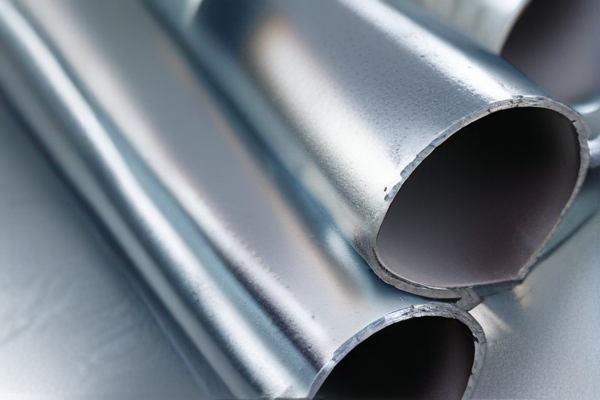

– Hot-Dip Galvanized: Steel is dipped in molten zinc, creating a thick, robust coating.

– Electro-Galvanized: Zinc is applied through electroplating, resulting in a smoother, thinner layer.

– Pre-Galvanized: Steel is galvanized in coil form before being fabricated.

– Galvannealed: Combines hot-dip galvanizing with annealing, resulting in a matte finish that holds paint well.

– Painted Galvanized: After galvanizing, a paint layer is added for added durability and aesthetic appeal.

– Spangled Galvanized: This type shows a unique, decorative pattern on the surface, which is a result of the crystallization process of zinc.

Applications and Uses:

– Construction: Used in roofing, wall panels, and support beams.

– Automotive: Applied in car bodies and parts to resist rust.

– Utility Poles: Ensures long-lasting outdoor use.

– Agriculture: Utilized in fencing, silos, and animal pens.

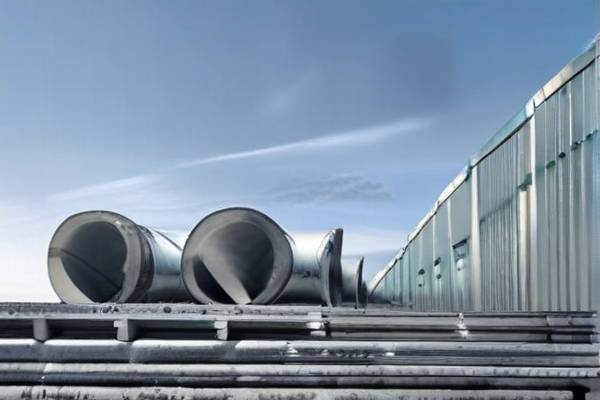

– HVAC Systems: Ductwork and components benefit from corrosion resistance.

– Marine: Protects parts exposed to harsh marine environments.

Benefits:

– Durability: Extends lifespan of steel products.

– Cost-Effective: Less maintenance compared to non-galvanized steel.

– Environmentally Friendly: Zinc is recyclable.

– Aesthetic Appeal: Various finishes available for different visual needs and preferences.

– Strength: Maintains structural integrity while providing corrosion protection.

Considerations:

– Initial Cost: Can be more expensive than non-galvanized steel.

– Weight: Adds extra weight to the steel.

– Surface Smoothness: Hot-dip galvanizing can lead to a rougher surface compared to other types.

Galvanized metal is steel coated with a protective layer of zinc to prevent rusting. This durable, corrosion-resistant material is widely used in various industries due to its longevity and strength.

– Construction: Used for structural frames, beams, and roofing materials.

– Automotive: Employed in car bodies and chassis for rust resistance.

– Agriculture: Utilized for fencing, water tanks, and equipment.

– Electrical: Used in cable trays, conduits, and light poles.

– Plumbing: Applied for pipes and pipe fittings.

– Household: Common in appliances, furniture, and home decor.

– Marine: Vital for shipbuilding and offshore structures.

– Energy: Used in wind turbines and solar panel frames.

– Public Infrastructure: Incorporated into guardrails, signposts, and bridges.

– Tools and Hardware: Found in nuts, bolts, and fasteners.

– Railroad: Used in track components and railcars.

– HVAC Systems: Applied in ductwork and air conditioning units.

– Outdoor Furniture: Preferred for its weather-resistant properties.

– Storage: Used in storage racks and pallet shelves.

– Aviation: Utilized in certain parts of aircraft for longevity.

Galvanized metal delivers high performance in diverse environments, making it a versatile and reliable choice for many applications.

Galvanized metal is a form of steel coated with a layer of zinc to provide increased resistance to corrosion and rust. This process extends the metal’s life span and makes it ideal for various applications, including construction, automotive, and household products.

The galvanization process typically involves immersing the metal in a hot zinc bath. The zinc reacts with the underlying steel to form a series of zinc-iron alloy layers, offering robust protective qualities. This results in a finish that can withstand harsh environmental conditions, reducing maintenance needs.

SourcifyChina offers high-quality galvanized metal products sourced from reliable Chinese manufacturers. Their focus is on ensuring that the materials meet international quality standards, offering competitive pricing without compromising durability and performance. This makes SourcifyChina an excellent partner for businesses requiring dependable metal materials.

Overall, galvanized metal is a practical choice for any project demanding resilience and longevity. With suppliers like SourcifyChina, access to top-tier materials has never been easier.

SourcifyChina is dedicated to ensuring the highest quality control standards in the manufacturing of galvanized metal. This process begins with rigorous selection of raw materials to ensure durability and resistance to corrosion.

The quality control process at SourcifyChina involves multi-stage inspections, starting from the initial raw material analysis to the final product evaluation. Each step aims to identify and eliminate defects before they affect product quality.

Automated systems and advanced technology play crucial roles in monitoring each phase of production. This ensures that the galvanization process adheres to international standards, providing a consistent and reliable end product.

SourcifyChina also employs skilled professionals who perform manual inspections for finer details that machines might miss. Their expertise ensures that only top-quality galvanized metal reaches the market.

Final tests include coating thickness measurements and salt spray tests to ascertain the metal’s ability to withstand harsh environments. These rigorous procedures guarantee that the galvanized metal will perform well under various conditions.

Customer feedback is another vital component of quality control at SourcifyChina. By listening to end-user experiences, they continually refine their processes to better meet market demands and expectations.

Through these meticulous quality control measures, SourcifyChina ensures their galvanized metal products are not only durable but also cost-effective. The comprehensive approach to quality assurance sets them apart in the competitive manufacturing landscape.

In summary, SourcifyChina employs a thorough and detailed quality control manufacturing process for galvanized metal. This ensures that every product they produce meets high standards of durability, reliability, and performance.

SourcifyChina specializes in sourcing and supplying high-quality galvanized metal across various industries. This type of metal is coated with a layer of zinc to prevent rusting, ensuring durability and longevity.

The company has extensive capabilities in providing both hot-dip galvanized and electro-galvanized metals. Each type of galvanization has its strengths: hot-dip for bulkier items needing heavy-duty corrosion protection, and electro-galvanized for lighter, precision tasks.

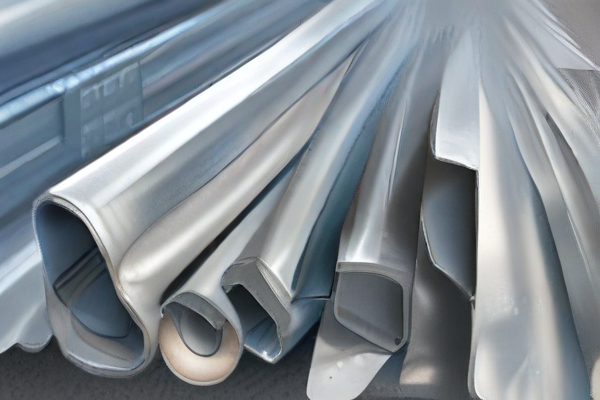

SourcifyChina’s expertise also extends to customized solutions, catering to specific client requirements. They ensure bespoke sizes, shapes, and zinc coating thickness, all with strict adherence to quality standards.

One of their standout features is rapid delivery and competitive pricing. Their efficient logistics network guarantees timely supply chains, minimizing downtime for clients and keeping projects on schedule.

Moreover, their customer service is second to none. They focus on clear communication, transparency, and post-purchase support, making the entire procurement process hassle-free and reliable.

In conclusion, SourcifyChina excels in providing top-notch galvanized metal solutions. Their blend of quality, customization, efficient delivery, and stellar customer service makes them a go-to choice for industries requiring galvanized materials.

Galvanized Metal and Its Benefits

Galvanized metal is steel that has been coated with a protective layer of zinc to prevent rusting. It offers several advantages:

– Corrosion Resistance: The zinc coating protects the steel underneath from rusting, making it highly durable in harsh environments.

– Longevity: Galvanized metal can last for decades with minimal maintenance, reducing long-term replacement costs.

– Cost-Effective: While the initial cost might be higher, the durability and low maintenance make it cost-effective over time.

– Versatility: Suitable for a wide range of applications, from construction to automotive parts.

– Aesthetic Appeal: The shiny, spangled finish provides a clean, attractive look.

– Eco-Friendly: Galvanizing uses less energy than other protective coatings and the metal is 100% recyclable.

– Strength: The galvanization process adds a layer of protection that enhances the structural integrity of the metal.

– Low Maintenance: Reduced need for frequent upkeep saves both time and money.

In summary, galvanized metal offers a combination of durability, cost-effectiveness, versatility, and aesthetic appeal, making it an excellent choice for various applications.

Galvanized metal is steel or iron that has been coated with a layer of zinc to prevent rusting. This process improves the metal’s durability and provides long-lasting protection against corrosion.

– Corrosion Resistance: The zinc coating acts as a barrier, keeping moisture and other elements from reaching the base metal and causing rust.

– Durability: The galvanization process enhances the metal’s ability to withstand harsh environmental conditions, extending its lifespan.

– Cost-Effective: Galvanized metal is generally less expensive over time as it requires less maintenance and has a longer service life compared to non-treated metals.

– Versatile Applications: It is suitable for a wide range of uses, including construction, automotive, and industrial applications.

– Low Maintenance: The zinc layer protects the metal so effectively that it requires very minimal maintenance, reducing the need for frequent repairs or replacements.

– Ease of Inspection: Any damage to the galvanized coating is usually easy to detect, allowing for timely repairs that prevent further degradation.

– Aesthetic Appeal: The galvanization process can also give the metal a pleasing, shiny finish, enhancing the visual appeal of structures and products.

– Recyclability: Galvanized metal can be recycled without losing its protective properties, making it an environmentally friendly option.

– Adhesive Quality: The zinc coating provides a good surface for paint and other coatings to adhere to, making further customization easier.

– Standardization: Galvanized metal complies with many industry standards, ensuring consistent quality and performance across different applications.

SourcifyChina is a renowned sourcing company specializing in custom products and projects. They are experts in guiding clients through the complexities of manufacturing bespoke items in China, ensuring high-quality standards and cost efficiency.

Galvanized metal is a type of steel that has been coated with a layer of zinc to prevent rust and corrosion. This process enhances the metal’s durability and longevity, making it ideal for outdoor and industrial applications where exposure to moisture and elements is a concern.

Custom projects from SourcifyChina often incorporate galvanized metal due to its robust, weather-resistant properties. This material is particularly popular in construction, automotive, and marine industries, where both strength and durability are essential.

The company focuses on thorough quality checks and precise specifications to meet client requirements for galvanized metal components. From design to delivery, SourcifyChina ensures that every custom product upholds the highest standards, aligned with international norms.

In conclusion, SourcifyChina’s expertise in sourcing galvanized metal for custom projects offers clients a reliable solution for high-quality, long-lasting products. Their comprehensive approach guarantees satisfaction and excellence, from initial concept to final production.

SourcifyChina specializes in the sourcing and procurement of galvanized metal products, providing essential solutions for various industries ranging from construction to automotive. Galvanized metal, a primary offering of SourcifyChina, is steel that has been coated with a layer of zinc to prevent rusting and enhance durability. This zinc coating acts as a protective barrier against corrosion, significantly extending the lifespan of the metal and making it a cost-effective choice for many applications. SourcifyChina leverages its extensive network of reliable manufacturers and suppliers in China to offer high-quality galvanized metal at competitive prices, ensuring that clients receive superior products tailored to their specific needs. The company prides itself on its rigorous quality control processes, timely delivery, and exceptional customer service, making it a trusted partner for businesses globally. Through its dedicated sourcing efforts, SourcifyChina continuously contributes to the optimization of supply chains, helping businesses achieve efficiency and sustainability.

Galvanized metal, primarily steel coated with a layer of zinc, is extensively utilized in Aerospace, Defense, and Marine applications due to its exceptional corrosion resistance, strength, and durability. In aerospace engineering, where materials are routinely exposed to harsh atmospheric conditions, galvanized components contribute to the longevity and reliability of aircraft structures. The zinc coating acts as a sacrificial layer, preventing oxidation of the underlying steel, ensuring that critical components like landing gears, engine mounts, and structural frames maintain their integrity over extended periods. This not only reduces maintenance costs but also enhances the safety and performance of aerospace vehicles, making galvanized metal an indispensable material in the industry.

In defense applications, galvanized metal is employed in the construction of military vehicles, armor plating, weapon systems, and various support structures. The protective zinc layer provides resilience against the corrosive effects of moisture, chemicals, and extreme temperatures, which are commonly encountered in combat and operational environments. This durability is crucial for maintaining the functionality and effectiveness of defense equipment over time. Similarly, in marine applications, galvanized metal is widely used for shipbuilding, offshore platforms, and other maritime structures exposed to saltwater and high humidity. The enhanced resistance to rust and corrosion ensures that ships and marine facilities remain operational and safe, reducing the frequency and cost of repairs. Thus, the unique properties of galvanized metal make it a vital material across these critical sectors.

Galvanized metal, coated with a layer of zinc to prevent corrosion, is a crucial material in automotive applications. The automotive industry relies heavily on galvanized steel for manufacturing car bodies and other components. This coating enhances the durability and lifespan of vehicles by providing robust resistance to rust and other environmental factors. As cars are exposed to various climatic conditions, the protective zinc layer ensures that the metal components remain untainted, reducing maintenance costs and improving safety. Moreover, the ductility and strength of galvanized steel allow for complex shapes and forms, essential for modern automotive design and functionality. This makes galvanized metal not only a practical choice but also a strategic one for weight reduction and fuel efficiency through more aerodynamic and lighter vehicle structures.

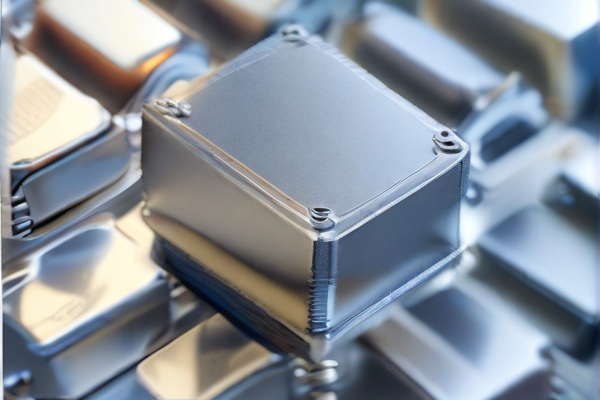

In the realm of electronics, galvanized metal finds extensive application due to its excellent conductive properties and corrosion resistance. Electronic devices, ranging from household appliances to sophisticated communication equipment, utilize galvanized components to ensure longevity and reliability. Casing and frames made from galvanized steel protect sensitive electronic circuits from environmental damage. Additionally, connectors and other small parts crafted from galvanized metal prevent electrical faults caused by corrosion. This property is particularly beneficial for outdoor electronic installations, like communication towers and satellite dishes, where prolonged exposure to harsh weather conditions can lead to significant degradation. Thus, the use of galvanized metal in electronics not only enhances the durability but also ensures the consistent performance of electronic products over time, proving to be indispensable in maintaining the integrity of modern electronic systems.

Galvanized metal, which is steel or iron coated with a protective layer of zinc, plays a pivotal role in the construction industry. The process of galvanization involves dipping the base metal into molten zinc, which forms a resilient barrier against corrosion and environmental damage. This protective layer not only extends the lifespan of the metal but also adds an additional layer of strength and durability. Common applications in construction include the use of galvanized steel in structural frameworks, roofing materials, and various outdoor fixtures such as fences, handrails, and street furniture. The metal’s ability to withstand extreme weather conditions and resist rust makes it an ideal choice for building materials that are exposed to the elements. Furthermore, galvanized metal requires minimal maintenance, thereby reducing long-term costs and ensuring structural integrity over extended periods.

In the realm of energy, galvanized metal is indispensable in the creation and maintenance of infrastructure necessary for power generation and distribution. Electrical power transmission towers, solar panel mounts, and wind turbine components are often constructed from galvanized steel to ensure longevity and reliability. The galvanization process helps these structures endure harsh environmental conditions, such as high humidity, salt spray, and extreme temperatures, which are common in areas like coastal regions and deserts. Moreover, galvanized components are also crucial in the development and protection of pipelines for natural gas and oil, where resistance to corrosion is essential to prevent leaks and potential environmental hazards. By significantly improving the durability and lifespan of metal components, galvanization ensures uninterrupted energy supply and reduces the need for frequent replacements, contributing to more sustainable and cost-effective energy infrastructure.

Galvanized metal, primarily steel or iron coated with a layer of zinc, offers immense value in the industrial equipment industry due to its enhanced durability and superior corrosion resistance properties. The galvanization process involves hot-dipping the base metal in molten zinc or electrochemical plating, forming a protective barrier that prevents rust and extends the lifespan of the equipment. This makes galvanized metal indispensable in manufacturing heavy machinery, agricultural implements, transportation systems, and construction equipment which are often subjected to harsh environments and exposure to moisture and chemicals. As a result, the industry significantly lowers maintenance costs and enhances reliability and safety, contributing to more efficient and cost-effective operations.

Moreover, the use of galvanized metal aligns with widespread industry standards for sustainability and environmental protection. The zinc coating, which can be recycled along with the base metal, minimizes waste and reduces the need for frequent replacements, thus conserving raw materials. Additionally, galvanized metals do not require the application of toxic paints or coatings, which further minimizes environmental impact and aligns with regulatory compliance requirements. Its application in industrial storage tanks, piping systems, and structural frameworks provides enduring performance, ensuring operational stability in varying climatic conditions. Ultimately, the integration of galvanized metal in industrial equipment not only meets rigorous performance demands but also supports ecological stewardship, reaffirming its crucial role in modern industry.

Galvanized metal, typically steel or iron coated with a layer of zinc, is widely recognized for its enhanced durability and resistance to corrosion. The process of galvanization involves submerging the metal in a bath of molten zinc, creating a robust coating that shields the underlying metal from environmental factors such as moisture and oxygen. This corrosion-resistant property is particularly advantageous in the healthcare industry, where the longevity and reliability of medical devices are paramount. Medical instruments, hospital beds, and diagnostic equipment that incorporate galvanized components are less susceptible to rust and wear, ensuring they maintain functionality and safety over extended periods of use.

In the realm of medical devices, the use of galvanized metal extends beyond simple support structures; it also plays a critical role in patient safety and asepsis. For example, in surgical environments where sterilization is crucial, galvanized metal surfaces are easier to clean and disinfect due to their smooth and non-porous nature. This characteristic helps in minimizing the risk of infection. Furthermore, high-precision medical devices, such as MRI and X-ray machines, often utilize galvanized metal for shielding and structural integrity, leveraging its electromagnetic interference (EMI) shielding properties. In summary, galvanized metal not only enhances the durability of medical devices but also supports stringent healthcare standards, ensuring safe and reliable patient care.

Galvanized metal, typically steel or iron coated in a protective layer of zinc, plays a crucial role in machining and manufacturing applications due to its enhanced corrosion resistance, which extends the life of components and structures. The galvanization process involves immersing the base metal in molten zinc to form a robust, durable coating that can withstand harsh environmental conditions. This property is particularly advantageous in industries like automotive, construction, and agriculture, where elements are frequently exposed to moisture, chemicals, and mechanical wear. In machining operations, galvanized metal offers the dual benefits of strong mechanical integrity and reduced maintenance needs, often translating to lower long-term operational costs.

In manufacturing, galvanized metal finds extensive application in producing a wide array of parts, from fasteners, pipes, and conduits to large assemblies like frames and housing units. The zinc coating not only provides superior protection against rust and corrosion but also retains the workability and machinability of the base metal. During fabrication, manufacturers must consider the unique properties of galvanized metal, such as its tendency to generate abrasive zinc particles, which may necessitate specialized tools and cutting fluids to mitigate wear. Moreover, understanding the thermal and mechanical behavior of galvanized coatings is essential to ensuring reliable welds and joint integrity. By integrating galvanized metals into production processes, manufacturers can deliver high-quality, durable products that perform well under challenging conditions, meeting both regulatory standards and customer expectations.

Here’s a list of frequently asked questions (FAQ) regarding the quality of galvanized metal work from SourcifyChina factory:

1. What is galvanized metal?

Galvanized metal is steel or iron that has been coated with a layer of zinc to protect it from corrosion and rust. The zinc coating acts as a barrier to environmental elements, preventing oxidation and extending the lifespan of the metal.

2. How does SourcifyChina ensure the quality of galvanized metal work?

SourcifyChina follows stringent quality control processes that include sourcing high-grade raw materials, employing skilled labor, and utilizing modern galvanizing techniques. Each product undergoes rigorous inspections and testing to meet international standards.

3. What types of galvanizing processes are used at SourcifyChina?

SourcifyChina commonly uses hot-dip galvanizing and electro-galvanizing processes. Hot-dip galvanizing involves dipping the metal into molten zinc, while electro-galvanizing uses an electric current to apply the zinc coating. Both methods have their own advantages depending on the application.

4. Can SourcifyChina produce custom galvanized metal products?

Yes, SourcifyChina offers customization services to meet specific client requirements. They can produce a wide range of custom shapes, sizes, and designs, tailored to fit various industrial needs.

5. What industries can benefit from SourcifyChina’s galvanized metal work?

Industries such as construction, automotive, furniture manufacturing, agriculture, and marine applications can benefit from using high-quality galvanized metal products from SourcifyChina due to their durability and resistance to rust.

6. What certifications does SourcifyChina hold for its galvanized metal products?

SourcifyChina holds several certifications, including ISO 9001 for quality management systems and ISO 14001 for environmental management. These certifications ensure that their products meet or exceed industry standards.

7. How does SourcifyChina handle orders and shipping for international clients?

SourcifyChina has an efficient order processing and logistics system. They offer flexible shipping options and handle all necessary documentation for smooth international trade. Customers can track their orders in real-time and receive updates on their shipment status.

This concise FAQ should provide a helpful overview of what to expect from SourcifyChina’s galvanized metal work.

Galvanized metal manufacturing involves applying a protective zinc coating to steel or iron to prevent rusting. At SourcifyChina Factory, the process typically starts with high-quality raw metal, which undergoes thorough cleaning to remove impurities. This ensures the zinc adheres properly during galvanization. Here’s a concise guide to their process:

1. Cleaning: The metal is cleaned using caustic solutions to remove oil, grease, and other contaminants. This is followed by pickling in an acidic solution to eliminate rust and scale, ensuring a clean surface.

2. Rinsing and Fluxing: After cleaning, the metal is rinsed to remove acidic residues and then dipped in a flux solution. The flux prevents oxidation before the galvanizing process.

3. Galvanizing: The prepared metal is immersed in a bath of molten zinc at temperatures around 450°C (842°F). The zinc reacts with the steel to form zinc-iron alloy layers, providing robust corrosion resistance.

4. Cooling and Inspection: Post-galvanizing, the metal is cooled in a quench tank to solidify the zinc coating. It undergoes rigorous inspection to ensure it meets quality standards, including coating thickness and adherence testing.

5. Finishing: Some products may require additional finishing processes, such as passivation or chromate coating, to enhance durability and appearance.

Benefits of SourcifyChina’s Galvanized Metal:

– Corrosion Resistance: Zinc coating provides long-lasting protection against rust and environmental elements.

– Durability: With proper maintenance, galvanized metal can last decades.

– Cost-Efficiency: Galvanization is a cost-effective method compared to maintaining untreated metals.

– Versatility: Suitable for various applications, from construction to automotive industries.

By adhering to strict quality control measures, SourcifyChina Factory ensures their galvanized metal products are dependable and meet international standards, making them a trusted choice for galvanization needs.

Sure, here is a succinct FAQ for sourcing galvanized metal from SourcifyChina factory:

—

What is galvanized metal?

Galvanized metal is steel or iron that has been coated with a layer of zinc to prevent rust and corrosion. The zinc acts as a protective barrier, extending the lifespan of the metal.

—

What types of galvanized metal do you offer?

SourcifyChina offers a range of galvanized metal products, including galvanized sheets, coils, pipes, and structural materials. We can cater to specific requirements based on size, thickness, and coating preferences.

—

What is the minimum order quantity (MOQ)?

The MOQ varies depending on the specific product and customization requirements. Generally, it ranges from 1 ton to 5 tons. Please contact us with your specific needs for a precise quote.

—

Can you provide customization services?

Yes, we offer customization services. You can specify the dimensions, coating thickness, and additional treatments according to your project needs. Custom orders are assessed on a case-by-case basis.

—

What standards do your galvanized metal products comply with?

Our galvanized metal products comply with international standards such as ASTM, JIS, and EN. We ensure our materials meet industry-specific requirements for safety and durability.

—

What is the lead time for orders?

Lead time varies depending on the order size and customization details. Generally, it ranges from 15 to 40 days after confirming the order. For more accurate timelines, please contact our sales team.

—

Do you provide samples?

Yes, we provide samples to help you verify the quality and specifications of our products. Sample costs and shipping fees may apply and can be discussed with our sales representatives.

—

What are the payment terms?

Our standard payment terms are 30% T/T in advance and 70% balance before shipment. We are open to negotiating different terms based on client requirements and order size.

—

How do you ensure product quality?

We have a stringent quality control process that includes raw material inspection, in-process quality checks, and final product testing. All products are tested for compliance with relevant standards before dispatch.

—

Do you handle international shipping?

Sourcing galvanized metal effectively, particularly from a supplier like SourcifyChina factory, involves a series of key steps and considerations. Here are some concise tips to help you navigate the process:

1. Understand Galvanized Metal: Galvanized metal is steel or iron coated with a layer of zinc to prevent rusting. The zinc acts as a barrier to corrosive elements, making the metal durable and long-lasting.

2. Identify Specific Requirements: Clearly define the specifications you need, such as thickness, size, and type (e.g., hot-dip or electro-galvanized). This ensures you communicate effectively with the supplier and receive the appropriate product.

3. Research Suppliers: Utilize platforms like Alibaba, Global Sources, or Made-in-China to find potential suppliers. Look for SourcifyChina factory on these platforms, read reviews, and check their certifications to confirm their credibility.

4. Request Samples: Before placing a large order, request samples of galvanized metal. This enables you to assess the quality and ensure it meets your standards.

5. Verify Certifications: Ensure that SourcifyChina factory holds the necessary certifications (e.g., ISO 9001) that guarantee quality management and compliance with international standards.

6. Negotiate Terms: Discuss and agree on terms like price, minimum order quantity (MOQ), lead time, and shipping. Clear terms help avoid misunderstandings and ensure smooth transactions.

7. Quality Control: Establish quality control measures, either by hiring a third-party inspection service or entrusting your requirements to the factory’s in-house quality assurance team.

8. Logistics Planning: Plan your logistics carefully. Consider factors like shipping time, customs clearance, and cost. Working with a reliable freight forwarder can streamline this process.

By following these tips, you can efficiently source high-quality galvanized metal from SourcifyChina factory, ensuring the material meets your project needs and standards.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.