Technology and Applications of what is the cnc machine

CNC Machines: Technology and Applications

Technology:

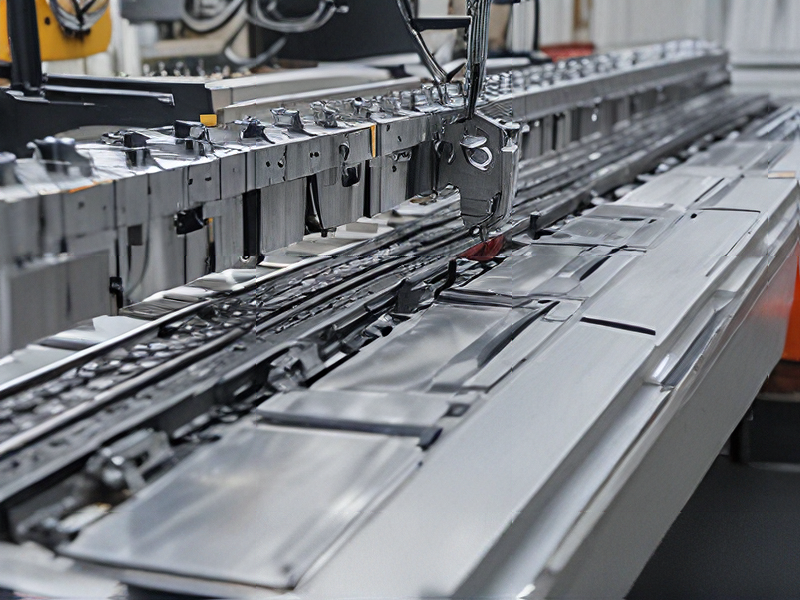

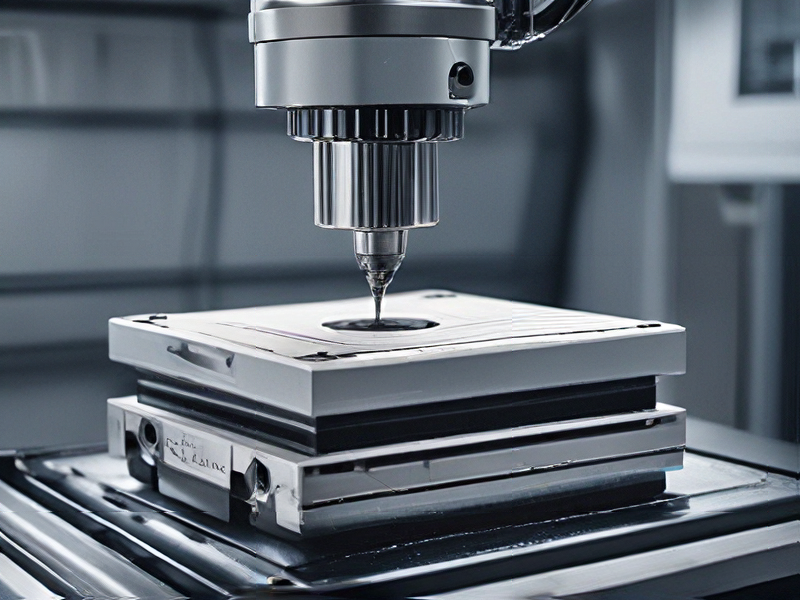

CNC (Computer Numerical Control) machines are automated milling devices that make industrial components without human assistance. They employ a computer system to control tools like lathes, mills, routers, and grinders, following programmed instructions to perform precise machining operations. The process begins with a CAD (Computer-Aided Design) model, which is translated into a CNC-compatible code using CAM (Computer-Aided Manufacturing) software. The code controls the machine’s movements, ensuring high accuracy and repeatability.

Applications:

1. Manufacturing:

CNC machines are pivotal in mass production, enabling consistent quality and precise specifications. They manufacture components for industries like automotive, aerospace, and electronics.

2. Prototyping:

They are essential in the rapid prototyping process, allowing engineers to test and iterate designs quickly.

3. Medical:

CNC machining is used to produce medical devices, implants, and prosthetics with high precision and custom specifications.

4. Aerospace:

The aerospace industry relies on CNC for producing complex parts with tight tolerances, such as turbine blades and structural components.

5. Woodworking:

CNC routers cut intricate designs in wood, producing furniture, cabinetry, and decorative items with detailed craftsmanship.

6. Jewelry:

CNC machines create intricate jewelry designs, ensuring precision and uniformity in each piece.

CNC machines revolutionize manufacturing by reducing manual labor, enhancing precision, and increasing production speed. Their versatility and precision make them indispensable across various industries, driving innovation and efficiency in modern manufacturing processes.

Quality Testing Methods for what is the cnc machine and how to control quality

CNC machines (computer numerical control) demand stringent quality control due to their precision engineering.

Testing Methods:

* Dimensional Inspection: Using calipers, micrometers, and coordinate measuring machines (CMMs) to verify part dimensions against blueprints.

* Surface Finish Analysis: Profiling instruments and optical comparators assess surface roughness and smoothness.

* Functionality Testing: Simulating real-world operations to ensure parts function correctly.

* Material Testing: Evaluating material properties like hardness, tensile strength, and fatigue resistance.

* Process Capability Studies: Analyzing process variations to determine if they meet specified tolerances.

Quality Control Measures:

* Tooling Inspection: Regularly calibrating and inspecting tools for wear and damage.

* Machine Calibration: Periodically calibrating the CNC machine for accuracy and repeatability.

* Workholding Systems: Ensuring workpieces are securely held during machining to prevent movement and dimensional errors.

* Process Monitoring: Using sensors and data analysis to track key process parameters and identify deviations.

* Statistical Process Control (SPC): Implementing SPC charts to monitor process stability and detect trends.

By implementing these rigorous testing methods and quality control measures, manufacturers can ensure the accuracy, reliability, and precision of CNC machined parts.

Tips for Procurement and Considerations when Purchasing from what is the cnc machine

When procuring a CNC (Computer Numerical Control) machine, several tips and considerations are essential to ensure a successful purchase:

Tips for Procurement

1. Define Requirements:

– Clearly outline the specific tasks and materials the CNC machine will handle. This helps in selecting the right type of CNC machine, whether it’s a milling machine, lathe, router, or another type.

2. Budget Planning:

– Determine a realistic budget that includes not only the cost of the machine but also installation, training, maintenance, and potential upgrades.

3. Vendor Research:

– Investigate various vendors and manufacturers. Look for reviews, testimonials, and case studies to gauge reliability and service quality.

4. Technical Support and Service:

– Ensure the vendor provides robust after-sales support and service. This includes warranties, availability of spare parts, and technical assistance.

5. Training and Usability:

– Consider the level of training required for operators. Machines with user-friendly interfaces and comprehensive training programs can reduce downtime and increase productivity.

6. Future-Proofing:

– Choose a machine with scalability and upgrade options to accommodate future needs and technological advancements.

Considerations

1. Machine Specifications:

– Evaluate the machine’s speed, precision, and capacity. Ensure it meets the specific requirements of your projects.

2. Software Compatibility:

– Verify that the CNC machine is compatible with your existing software and design tools. Integration is key for seamless operation.

3. Energy Consumption:

– Consider the machine’s energy efficiency to manage operational costs and environmental impact.

4. Space Requirements:

– Ensure you have adequate space for the machine, including room for operation, maintenance, and any auxiliary equipment.

5. Safety Features:

– Look for machines with built-in safety features to protect operators and reduce the risk of accidents.

6. Cost of Ownership:

– Analyze the total cost of ownership, including initial purchase, maintenance, operation, and potential downtime costs.

By following these tips and considering these factors, you can make an informed decision and select a CNC machine that best fits your operational needs and budget.

FAQs on Sourcing and Manufacturing from what is the cnc machine in China

FAQs on Sourcing and Manufacturing CNC Machines from China

1. What is a CNC machine?

A Computer Numerical Control (CNC) machine is a device used in manufacturing that utilizes pre-programmed software to control the movement of tools and machinery. These machines can perform a variety of tasks such as cutting, drilling, milling, and turning with high precision.

2. Why source CNC machines from China?

China is a leading manufacturer of CNC machines, offering competitive prices, a wide variety of models, and advancements in technology. The lower labor and production costs in China make it an attractive option for sourcing high-quality CNC machines.

3. How to identify reliable CNC machine manufacturers in China?

Look for manufacturers with a good track record, certifications like ISO, and positive customer reviews. Websites like Alibaba, Made-in-China, and Global Sources can help you find reputable suppliers. Visiting trade shows and exhibitions in China also provides opportunities to meet manufacturers directly.

4. What factors should I consider when selecting a CNC machine?

Consider the type of materials you will be working with, the complexity of the tasks, the precision required, the machine’s size and power, and the availability of technical support and spare parts.

5. How to ensure the quality of CNC machines from China?

Request samples or trial runs, check for quality certifications, and consider third-party inspections. Working with a sourcing agent can also help verify the quality and reliability of the machines.

6. What are the shipping and customs considerations?

Understand the Incoterms (FOB, CIF, etc.) to know what costs are included in the price. Be aware of shipping times, import duties, and taxes. Using a reputable logistics company can simplify the shipping process.

7. How to handle after-sales service and maintenance?

Ensure the manufacturer provides a warranty and has a responsive after-sales service team. It’s beneficial to have local technicians trained in maintaining and repairing the CNC machines.

By considering these factors, you can effectively source and manufacture CNC machines from China, ensuring high quality and cost-efficiency.