Technology and Applications of wooden cutting machine

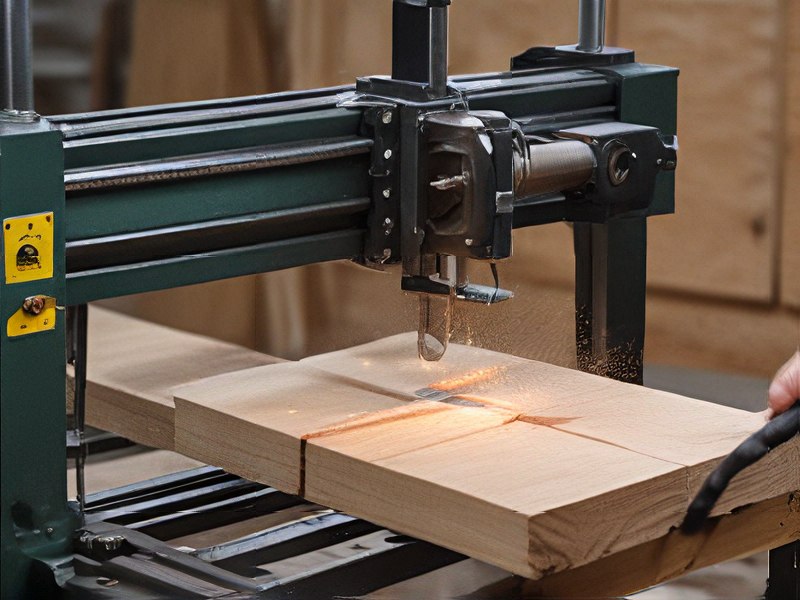

Wooden cutting machines, also known as CNC routers or wood cutting CNCs, utilize computer-aided design (CAD) and computer numerical control (CNC) technology to precisely cut, shape, and engrave wood.

These machines are widely used in various industries:

* Furniture Manufacturing: Creating intricate designs, custom cabinets, and wooden furniture components.

* Construction: Cutting and shaping wooden beams, panels, and other structural elements.

* Sign Making: Producing wooden signs, plaques, and decorative elements with precision engravings.

* Woodworking & Craft: Enabling hobbyists and artisans to create intricate wooden models, toys, and art pieces.

Wooden cutting machines offer advantages like high accuracy, repeatability, and efficient material utilization.

They come in various sizes and configurations, ranging from small desktop models to large industrial machines. The choice depends on the scale and complexity of the woodworking project.

Quality Testing Methods for wooden cutting machine and how to control quality

Quality testing for wooden cutting machines involves several methods to ensure precision, durability, and safety. Here are key methods and quality control measures:

Testing Methods:

1. Dimensional Accuracy Test:

– Laser Measurement: Use laser tools to measure cut dimensions and ensure they meet specified tolerances.

– Calipers and Micrometers: Verify the accuracy of smaller components and cuts.

2. Cutting Performance Test:

– Material Samples: Test on different types of wood to evaluate the machine’s performance, speed, and quality of cuts.

– Edge Quality Inspection: Check for smoothness and consistency of the cut edges.

3. Durability and Reliability Test:

– Continuous Operation: Run the machine continuously for extended periods to assess its durability.

– Vibration Analysis: Monitor vibrations to detect potential issues with bearings or alignment.

4. Safety Test:

– Emergency Stop Function: Ensure the emergency stop button works effectively.

– Guarding and Shields: Verify all safety guards and shields are in place and functioning.

5. Noise Level Test:

– Decibel Meter: Measure the noise level during operation to ensure it is within acceptable limits.

Quality Control Measures:

1. Standard Operating Procedures (SOPs):

– Develop and implement SOPs for machine operation, maintenance, and inspection to ensure consistency and reliability.

2. Regular Maintenance:

– Schedule regular maintenance checks to identify and rectify wear and tear before they cause significant issues.

3. Training:

– Provide comprehensive training for operators to ensure they understand how to use and maintain the machine correctly.

4. Quality Audits:

– Conduct periodic audits to ensure all quality control procedures are being followed.

5. Feedback Loop:

– Implement a system for operators and customers to report issues, which are then analyzed and addressed promptly.

6. Calibration:

– Regularly calibrate measurement tools and sensors to maintain accuracy.

By combining these testing methods and quality control measures, manufacturers can ensure that wooden cutting machines perform reliably and produce high-quality cuts.

Tips for Procurement and Considerations when Purchasing from wooden cutting machine

Purchasing a wooden cutting machine requires careful consideration for optimal performance and longevity.

Key Procurement Tips:

* Define Your Needs: Determine the types of wood you’ll work with, the desired cutting precision, and the volume of work.

* Types of Machines: Explore different options like band saws, scroll saws, table saws, and CNC routers, each suited for specific tasks.

* Motor Power & Blade Quality: A powerful motor ensures smooth cutting through thick wood, while sharp, high-quality blades guarantee accurate and clean cuts.

* Safety Features: Prioritize machines with safety guards, emergency stops, and dust collection systems to protect yourself and your workspace.

* Budget & Maintenance: Factor in the initial cost, ongoing maintenance, and potential blade replacement expenses.

Considerations:

* Workspace Size: Ensure the machine fits comfortably in your workspace, allowing for safe operation and maneuverability.

* Portability: Consider portability if you need to move the machine frequently.

* User-Friendliness: Look for intuitive controls and features that simplify operation, especially if you’re a beginner.

* Brand Reputation & Warranty: Choose reputable brands with good customer support and reliable warranties.

Thoroughly research and compare different models before making a purchase.

FAQs on Sourcing and Manufacturing from wooden cutting machine in China

## FAQs on Sourcing & Manufacturing Wooden Cutting Machines in China

1. Where can I find reliable wooden cutting machine suppliers in China?

Numerous online platforms like Alibaba, Global Sources, and Made-in-China connect you with various manufacturers and suppliers. Trade shows focused on woodworking machinery are also excellent resources for sourcing.

2. What are the key factors to consider when choosing a supplier?

Prioritize:

* Experience and Reputation: Look for established suppliers with positive customer reviews and industry recognition.

* Product Quality: Request samples and inspect their manufacturing facilities to assess quality standards.

* Communication: Effective communication is crucial. Ensure the supplier is responsive, transparent, and understands your needs.

* Pricing and Payment Terms: Compare quotes from multiple suppliers and negotiate favorable payment terms.

3. What are the common types of wooden cutting machines in China?

Popular options include:

* CNC Router: For intricate designs and precise cuts.

* Laser Cutter: Ideal for delicate work and engraving.

* Plasma Cutter: Suited for thicker materials.

* Panel Saw: For straight and efficient cutting of large panels.

4. What are the typical lead times for manufacturing and delivery?

Lead times vary depending on the complexity of the machine and the supplier’s production capacity. Expect a timeframe of 4-8 weeks for standard machines.

5. How can I ensure the smooth shipment of my wooden cutting machine from China?

Work with a reputable freight forwarder who specializes in handling machinery exports. Ensure proper packaging, insurance, and clear documentation.